| Models |

|

|

|

|

Resource

Allocation Problem

|

|

|

|

|

|

Resource

Allocation Problem

|

|

|

|

Statement

|

|

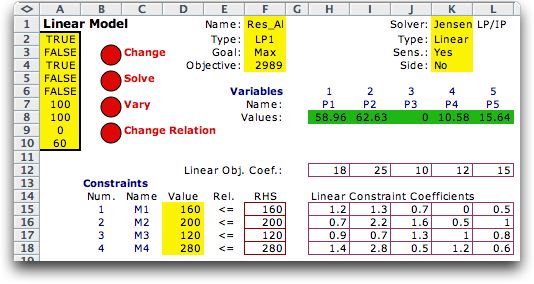

The type of problem most often

identified with the application of linear program is the problem

of distributing scarce resources among alternative activities.

The Product Mix problem is a special case. In this example,

we consider a manufacturing facility that produces five different

products

using four machines.

The scarce

resources are the times available on the machines and the alternative

activities are the individual production volumes. The machine

requirements in hours per unit are shown for each product in

the table. With the exception of product 4 that does not require

machine 1, each product must pass through all four machines.

The unit profits are also shown in the table.

The facility has four machines of type 1, five of type 2,

three of type 3 and seven of type 4. Each machine operates

40 hours per week. The problem is to determine the optimum

weekly production quantities for the products. The goal is

to maximize total profit. In constructing a model, the first

step is to define the decision variables; the next step is

to write the constraints and objective function in terms of

these variables and the problem data. In the problem statement,

phrases like "at least," "no greater than," "equal

to," and "less than or equal to" imply one or

more constraints.

Machine data and processing requirements

(hrs./unit)

|

Machine |

Quantity |

Product 1 |

Product 2 |

Product 3 |

Product 4 |

Product 5 |

|

M1 |

4 |

1.2 |

1.3 |

0.7 |

0.0 |

0.5 |

|

M2 |

5 |

0.7 |

2.2 |

1.6 |

0.5 |

1.0 |

|

M3 |

3 |

0.9 |

0.7 |

1.3 |

1.0 |

0.8 |

|

M4 |

7 |

1.4 |

2.8 |

0.5 |

1.2 |

0.6 |

|

Unit profit, $ |

—— |

18 |

25 |

10 |

12 |

15 |

|

Model |

|

Variable Definitions

Pj : quantity of

product j produced, j = 1,...,5

Machine Availability Constraints

The number of hours available on each machine type is 40 times

the number of machines. All the constraints are dimensioned

in hours. For machine 1, for example, we have 40 hrs./machine ¥ 4

machines = 160 hrs.

|

M1 : |

1.2P1 + 1.3P2 + 0.7P3 + 0.0P4 + 0.5P5 < 160 |

|

M2 : |

0.7P1 + 2.2P2 + 1.6P3 + 0.5P4 + 1.0P5 < 200 |

|

M3 : |

0.9P1 + 0.7P2 + 1.3P3 + 1.0P4 + 0.8P5 < 120 |

|

M4 : |

1.4P1 + 2.8P2 + 0.5P3 + 1.2P4 + 0.6P5 < 280 |

Nonnegativity

Pj > 0

for j = 1,...,5

Objective Function

The unit profit coefficients are given in the table. Assuming

proportionality, the profit maximization criterion can be written

as:

Maximize Z = 18P1+

25P2 + 10P3 +

12P4 + 15P5 |

Solution |

|

The model constructed with the

Math Programming add-in is shown below. The model has been

solved with the Jensen LP add-in. We note several things about

the solution.

- The solution is not integer. Although practical considerations

may demand that only integer quantities of the products be

manufactured, the solution to a linear programming model

is not, in general, integer. To obtain an optimum integer

answer, one must specify in the model that the variables

are to be integer. The resultant model is called an integer

programming model and is much more difficult to solve for

larger models. The analyst should report the optimal solution

as shown, and then if necessary, round the solution to integer

values. For this problem, rounding down the solution to:

P1 = 59, P2 = 62, P3 = 0, P4 = 10 and P5 = 15 will result

in a feasible solution, but the solution may not be optimal.

- The solution is basic. The simplex solution procedure used

by the Jensen LP add-in will always return a basic solution.

It will have as many basic variables as there are constraints.

As described elsewhere in this site, basic variables are

allowed to assume values that are not at their upper or lower

bounds. Since there are four constraints in this problem,

there are four basic variables, P1, P2, P4 and P5. Variable

P3 and the slack variables for the constraints are the nonbasic

variables.

- All the machine resources are bottlenecks for the optimum

solution with the hours used exactly equal to the hours available.

This is implied by the fact that the slack variables for

the constraints are all zero.

- This model does not have lower or upper bounds specified

for the variables. This is an option allowed with the Math

Programming add-in. When not specified, lower bounds on variables

are zero, and upper bounds are unlimited.

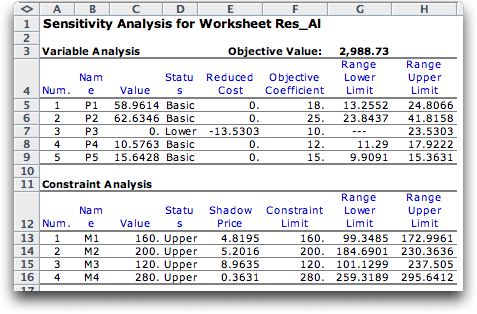

The sensitivity analysis amplifies the solution. The analysis

shows the results of changing one parameter at a time. While

a single parameter is changing, all other problem parameters

are held constant. For changes in the limits of tight constraints,

the values of the basic variables must also change so that

the equations defining the solution remain satisfied.

Variable Analysis

- The "reduced cost" column indicates the increase

in the objective function per unit change in the value of

the associated variable. The reduced costs for the basic

variables are all zero because the values of these variables

are uniquely determined by the problem parameters and cannot

be changed.

- The reduced cost of P3 indicates that if this variable

were increased from 0 to 1 the objective value (or profit)

will decrease by $13.53. It is not surprising that the reduced

cost is negative since the optimum value of P3 is zero. When

a nonbasic variable changes, the basic variables change so

that the equations defining the solution remain satisfied.

There is no information from the sensitivity analysis on

how the basic variables change or how much P3 can change

before the current basis becomes infeasible. Note that the

reduced costs are really derivatives that indicate the rate

of change. For degenerate solutions (where a basic variable

is at one of its bounds) the amount a nonbasic variable may

change before a basis change is required may actually be

zero.

- The ranges at the right of the display indicate how far

the associated objective coefficient may change before the

current solution values (P1 through P5) must change to maintain

optimality. For example, the unit profit on P1 may assume

any value between 13.26 and 24.81. The "---" used

for the lower limit of P3 indicates an indefinite lower bound.

Since P3 is zero at the optimum, reducing its unit profit

by any amount will make it even less appropriate to produce

that product.

Constraint Analysis

- A shadow price indicates the increase in the objective

value per unit increase of the associated constraint limit.

The status of all the constraints are "Upper" indicating

that the upper limits are tight. From the table we see that

increasing the hour limit of 120 for M3 increases the objective

value by the most ($8.96), while increasing the limit for

M4 increases the objective value by the least ($0.36). Again,

these quantities are rates of change. When the solution is

degenerate, no change may actually be possible.

- The ranges at the right of the display indicate how far

the limiting value may change while keeping the same optimum

basis. The shadow prices remain valid within this range.

As an example consider M1. For the solution, there are 160

hours of capacity for this machine. The capacity may range

from 99.35 hours to 173 hours while keeping the same basis

optimal. Changes above 120 cause an increase in profit of

$4.82 per unit, while changes below 120 cause a reduction

in profit by $4.82 per unit. As the value of one parameter

changes, the other parameters remain constant and the basic

variables change to keep the equations defining the solution

satisfied.

|

General Resource Allocation Model

|

| |

It is common to describe a problem

class with a general algebraic model where numeric values are

represented by lower case letters usually drawn from the early

part of the alphabet. Variables are given alphabetical representations

generally drawn from the later in the alphabet. Terms are combined

with summation signs. The general resource allocation model

is below. When the parameters are given specific numerical

values the result is an instance of the general model.

|

| |

|

|