|

|

|

Process

Flow Optimization |

|

-

Resources and Materials |

|

|

|

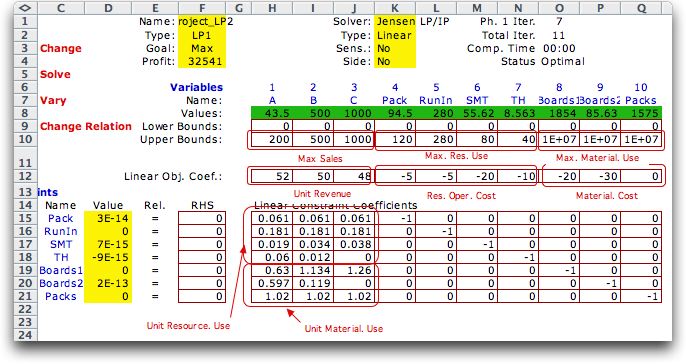

The second option produces

a linear programming model that adds to the product variables,

variables that specify the time used on each resource

and the amounts of each raw material. It includes constraints

on the amounts of raw materials and the amounts of resources

available. It determines the optimum product mix with

these constraints included. |

Clicking OK presents

the Linear Model dialog shown below. As for the LP1 model,

the number of variables and number of constraints can be increased,

but not decreased.

|

| |

|

| |

The figure below shows

the model constructed with the second model option. The data

for the model is derived directly from the data on the Project

Worksheet. The model produced can be solved with the built in

Excel optimizer (Solver add-in) or the LP Solver Add-in. The

solution shown is the optimum product mix for the example. In

addition to the sales value, the hours required for the resources

and the amounts of the raw materials are explicitly displayed

in the variable value row of the LP solution. The model allows

simple upper bounds for the raw material amounts and resource

times. |

| |

|

| |

The optimum sales quantities are transferred

to the Sales column on the Project worksheet. The numbers

in the column are linked by formula to the Project LP2 worksheet,

and the column is colored yellow. When features of the LP model

are changed and the model solved, the solution is reflected

in the sales column. The user can change numbers in the sales

column, but the automatic links to the Project LP2 worksheet

are lost. |

| |

|

| |

|

|