|

|

|

|

Inventory

Theory

|

|

-

General Considerations

|

|

Flow, Inventory and Time |

|

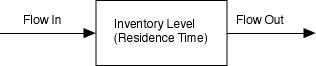

An inventory is represented in

the simple diagram of Fig. 1. Items flow into the system, remain

for a time and then flow out. Inventories occur whenever the

time an individual enters is earlier than when it leaves. During

the intervening interval the item is part of the inventory.

Figure 1. A system component with inventory

For example, say the box in Fig. 1 represents

a manufacturing process that takes a fixed amount of time. A

product entering the box at one moment leaves the box one hour

later. Products arrive at a rate of 100 per hour. Clearly, if

we look in the box, we will find some number of items. That

number is the inventory level. The relation between flow, time

and inventory level that is basic to all systems is

Inventory Level

= (Flow Rate)(Residence Time) |

(1) |

The flow rate must be expressed in the same time

units as the residence time. For the example, we have

Inventory Level = (100 products/hour)(1

hour) = 100 products.

When the factors in this expression are not constant

in time, the expression relates time-averaged quantities.

Whenever two of the factors in the above expression

are given, the third is easily computed. Consider a queuing

system for which customers are observed to arrive at an average

rate of 10 per hour. When the customer finds the servers busy,

he or she must wait. Customers in the system, either waiting

or being served, are the inventory for this system. Using a

sampling procedure we determine that the average number of customers

in the inventory is 5. We ask, how long, on the average, is

each customer in the system? Using the relation between the

flow, time and inventory, we determine the answer as 0.5 hours.

The relation receives extensive use in queuing analysis where

it is called Little's Law.

The relation between time and inventory is important,

because very often the reducing the throughput time for a system

is just as important as reducing the inventory level. Since

they are proportional, changing one factor inevitably changes

the other. |

The Inventory Level |

| |

The inventory level depends on

the relative rates of flow in and out of the system. Define

y(t) as the rate of input flow at time t

and Y(t) the cumulative flow into the system.

Define z(t) as the rate of output flow at

time t and Z(t) as the cumulative

flow out of the system. The inventory level, I(t)

is the cumulative input less the cumulative output.

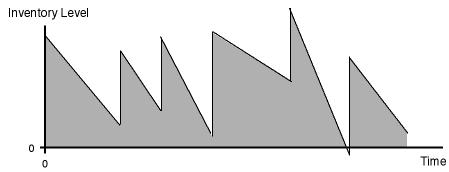

Fig. 2 represents the inventory for a system when the rates

vary with time.

Figure 2. Inventory fluctuations as a function

of time.

The figure might represent a raw material inventory.

The flow out of inventory is a relatively continuous activity

where individual items are placed into the production system

for processing. To replenish the inventory, an order is placed

to a supplier. After some delay time, called the lead-time,

the raw material is delivered in a lot of a specified amount.

At the moment of delivery, the rate of input is infinite and

at other times it is zero. Whenever the instantaneous rates

of input and output to a component are not the same, the inventory

level changes. When the input rate is higher, inventory grows;

when output rate is higher, inventory declines.

Usually the inventory level remains positive.

This corresponds to the presence of on hand inventory. In cases

where the cumulative output exceeds the cumulative input, the

inventory level is negative. We call this a backorder or shortage

condition. A backorder is a stored output requirement that is

delivered when the inventory finally becomes positive. Backorders

are possible for some systems, while they are not for others.

A finished product inventory, for example, may promise later

delivery if a customer arrives to find no product available.

Alternatively, a customer with alternative suppliers may go

elsewhere and the sale is lost. In cases where backorders are

impossible, the inventory level is not allowed to become negative.

The demands on the inventory that occur while the inventory

level is zero are called lost sales. |

Variability, Uncertainty and Complexity |

| |

There are many reasons for variability

and uncertainty in inventory systems. The rates of withdrawal

from the system may depend on customer demand that is often

variable in time and uncertain in amount. There may be returns

from customers. Lots may be delivered with defects causing uncertainty

in quantities delivered. The lead-time associated with an order

for replenishment depends on the production time of the supplier,

which is usually variable and not known with certainty. The

response of a customer to a shortage condition may be uncertain.

Inventory systems are often complex with one component of the

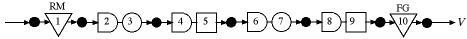

system feeding another. Fig. 3 shows a simple serial manufacturing

system producing a single product.

Figure 3. A manufacturing system with several

locations for inventories

We identify planned inventories in Fig. 3 as inverted

triangles, particularly the raw material (1) and finished

goods inventories (10). Material passing through the production

process is often called work in process (WIP). These

are materials waiting for processing as in the delays

of the figure (2, 4, 6, 8), materials undergoing processing

in the operations (3, 7), or materials undergoing inspection

in the inspections (5, 9). All the components of inventory

contribute to the cost of production in terms of handling and

investment costs, and all require management attention.

For our analysis, we often consider one component

of the system separate from the remainder, particularly the

raw material or finished goods inventories. In reality, rarely

can these be managed independently. The material leaving a raw

material inventory does not leave the system, rather it flows

into the remainder of the production system. Similarly, material

entering a finished goods inventory comes from the system. Any

analysis that optimizes one inventory independent of the others

must provide less than an optimum solution for the system as

a whole. We consider inventories that are related by flow in

the WIP section of these pages.

Real inventory systems must face the dual curse

of variability and uncertainty, and are often embedded in complex

systems. In order to develop a theory to help manage inventories

it is necessary to construct mathematical models that are abstractions

of reality. Every model neglects certain aspects of the problem

to obtain results that may be of use. When we describe simplified

models on the following pages, we do not actually believe that

the models actually are perfectly accurate. On the contrary,

if the modeller attemps to create a model to be an accurate

reflection of reality it would be too complex to be of value.

Simplified models do provide results that can be used for decision-making.

Whether a model has sufficient accuracy to make the results

valid in a particular context must be judged by those charged

with applying the model. |

| |

|

|