|

|

Inventories are materials stored, waiting for processing,

or experiencing processing. They are ubiquitous in modern business.

Observation of almost any company balance sheet reveals that

a very significant part of its assets comprise inventories

of raw materials, products within the production process, or

finished products.

Because of their practical and economic importance, the subject

of inventory control is a major consideration in many situations.

Questions must be constantly answered as to when and how much

raw material should be ordered, when a production order should

be released to the plant, what level of safety stock should

be maintained at a retail outlet, or how in-process inventory

is to be maintained in a production process. These questions

are amenable to quantitative analysis through the subject of

inventory theory. The Inventory Add-in add-in embodies some

of the mathematical results of inventory theory. The Inventory

Add-in is part of the OM/IE collection of the Jensen add-ins.

It is described at the website www.ormm.net.

This game simulates some of the stochastic systems considered

by the add-in and the subject of inventory theory.

|

| |

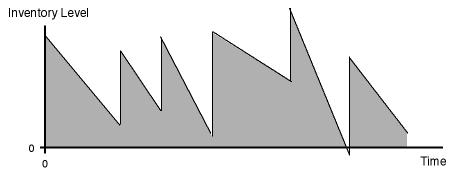

We consider here an inventory

holding a single product as illustrated in the figure below.

The figure might represent a raw material inventory. The flow

out of inventory is a relatively continuous activity where

individual items are placed into the production system for

processing. To replenish the inventory, an order is placed

to a supplier. After some delay time, called the lead-time,

the raw material is delivered in a lot of a specified amount.

At the moment of delivery, the rate of input is infinite and

at other times it is zero. Whenever the instantaneous rates

of input and output to a component are not the same, the inventory

level changes. When the input rate is higher, inventory grows;

when output rate is higher, inventory declines.

Usually the inventory level remains positive. This corresponds

to the presence of on hand inventory. In cases where demand

exceeds the available inventory customers must either wait

or sales may be lost. When the customer is willing to wait,

we show the shortage as a negative inventory value. We call

this a backorder or shortage condition. A backorder is a stored

output requirement that is delivered when the inventory finally

becomes positive. Backorders are possible for some systems,

while they are not for others. A finished product inventory,

for example, may promise later delivery if a customer arrives

to find no product available. The will generally be extra costs

when inventory is backordered.

Alternatively,

a customer with alternative suppliers may go elsewhere if he

or she finds the inventory empty. This is called a lost sale.

The inventory may go to zero, but will never be negative. The

demands on the inventory that occur while the inventory level

is zero are called lost sales. For most businesses, lost sales

are bad. There is generally a cost of goodwill suffered by

the disappointed customer. The cost is at least the value of

the profit foregone from a lost sale.

|