|

|

|

Simulation |

|

-

Inventory Model |

|

|

Here we illustrate the second model type available, the inventory

model. The simulation describes a reorder point - lot size

system. The inventory holds a single product and is reviewed

periodically, weekly for the example. The inventory level is

decreased by demand described as a random variable. When

the inventory level reaches some reorder point specified as

a parameter, an order is placed. The amount of the order is

also a parameter of the simulation. After a predetermined lead

time, the replenishment is delivered and added to the inventory.

During the lead-time, the inventory may be exhausted and shortages

may occur. We assume that shortages are backordered and satisfied

when the next order is delivered. An option models the lost

sales case.

There are costs associated with replenishment, backorders

and inventory level. We will construct a simulation of this

situation. The goal of the analysis might be to choose a reorder

point and lot size that minimizes the average daily cost. Simulation

does not answer that question directly, but it can be used

to evaluate alternative choices.

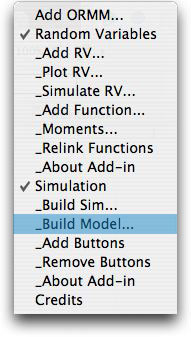

The model is constructed by choosing the Build Model command

and filling in the dialog that is presented. The model name

can contain no spaces or punctuation. The name is used to

identify various ranges on the worksheet and cannot be changed

after the worksheet is constructed. The default is to backorder

shortages, but the lost sales model is obtained if

that box is checked. The Control

Simulation box

operates the inventory one period at a time and the user makes

reorder decisions. The initial inventory is entered as a parameter,

but it may changed on the worksheet. The lead-time affects

the simulation structure and once it is defined here it cannot

be easily changed.

|

The Worksheet Model |

| |

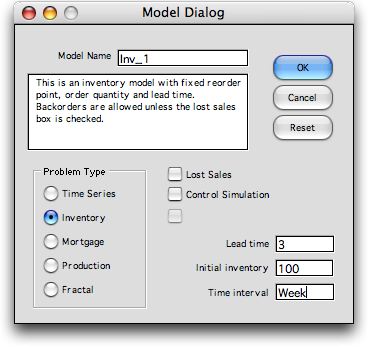

Pressing the OK button

on the model dialog, brings forth a second dialog that provides

the features of the multiline simulation model that will describe

the process. The problem name is fixed as the name given in

the Model dialog and the parameters are set to their proper

values. The numbers of columns may be increased to accommodate

additional model features, but they should not be reduced or

the program will not be able to build the inventory model.

As the worksheet is constructed, a third dialog

will ask for the distribution of the demand. For the example

we suppose that the demand is normally distributed random variable

with mean 25 per week and a standard deviation of 5. Pressing

OK for this dialog, builds the worksheet for the inventory model.

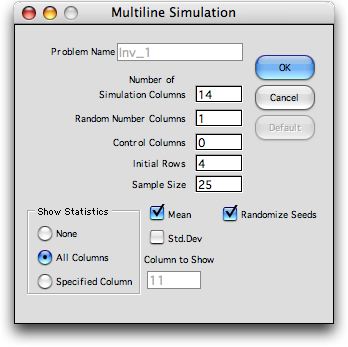

All expressions are automatically placed in row 1 and the random

variable and parameter definitions are placed on the worksheet.

The figure at the left shows the top corner of the worksheet.

The buttons control the operation of the simulation. |

| |

|

The parameters of the system are placed in columns B and

C starting at row 16. The order quantity (C17) and reorder

point (C19) are the decision variables. The initial inventory

is in C21 and the cost parameters are in C25, C27 and C29.

The mean and standard deviation of the demand are in C32

and C33. All these numbers may be changed to represent

the system under study.

The

lead-time parameter in C23 is shown in yellow. This indicates

that the lead-time should not be changed. Changing

the lead-time in C23will not affect the results because

it is fixed in the expressions defining the system. If you

want to analyze the system with a different lead-time,

create another model.

The seed in F13 is used for Monte Carlo simulation. It

controls the sequence of demands realized for the simulation.

Clicking the Simulate button changes the seed

and produces a new simulation run.

The Change button controls aspects of the simulation.

An option useful here is the number of observations in

the simulation. The Chart button produces a chart

of one of the simulated columns.

|

|

| |

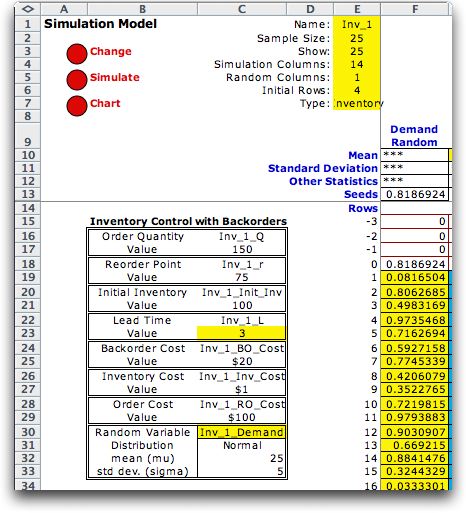

At the top of the worksheet

are simulation parameters in columns E and I. Results for the

simulation run are in column L. |

|

| |

The simulation model

is shown in two parts below. This model has a single random variable

for demand governed by the simulated values in column F. The

columns necessary for the simulation are columns G through T.

The model is simulated for 25 weeks, but only the first five

weeks are shown. The interesting result is in column T that shows

the cost per week. The other columns are necessary to determine

the replenishment orders, backorder amounts and inventory amounts. |

|

| |

The initial conditions

are in the rows labeled -3 through 0. The only nonzero value

shown is in cell K10. This cell holds a formula that links its

value to the initial inventory level in cell C21. |

|

| |

The cells in column V,

W and X summarize the results for the 25 simulated weeks. |

|

Row 1 |

| |

The simulation is implemented

by the formulas in table row 1, Row 19 on the worksheet. To create

the other rows of the simulation, we simply perform the Excel

function Fill Down on the simulation form. In this way

all the rows have the same formulas as row 1, but displaced in

reference. A few of the cells are named for the formulas.

- Inv_1_Demand is the range {C31...C33}. This range identifies

the normal distribution for the demand and specifies the

mean and standard deviation.

- Inv_1_r is the number in cell C19. This is the order point.

When the inventory position reaches the order point an order

must be placed.

- Inv_1_Q is the number in cell C17. It is the order quantity

that is placed at each replenishment order.

- Inv_1_BO_Cost , Inv_1_Inv_Cost, and Inv_1_RO_Cost are in

C25, C27 and C29 respectively. They are the cost parameters

for the inventory system.

|

Column |

Quantity |

Formula |

F |

Demand Random |

=SIM_rand(-F18) |

G |

Beginning Inventory |

=K18 |

H |

Delivery |

=O15 |

I |

Inventory + Delivery |

=G19+H19 |

J |

Demand |

=MAX(ROUND(RV_sim(Inv_1_Demand,-F19),0),0) |

K |

Ending Inventory |

=I19-J19 |

L |

On Order |

=L18-H19+O18 |

M |

Inventory Position |

=L19+K19 |

N |

Reorder |

=IF(M19<=Inv_1_r,1,0) |

O |

Order Quantity |

=IF(N19=1,Inv_1_Q,0) |

P |

Inv. Less Shortages |

=I19-J19 |

Q |

Fraction Backorder |

=IF(I19>0,IF(P19>0,0,-P19/ABS(J19)),IF(P19>0,-I19/ABS(J19),1)) |

R |

Back Orders |

=IF(Q19=1, -K19 -P19 /2,-MIN(K19,I19 )*Q19/2) |

S |

On Hand |

=IF(Q19=0, K19 +J19 /2,MAX(K19,I19 )*(1-Q19)/2) |

T |

Cost |

=S19*Inv_1_Inv_Cost + R19*Inv_1_BO_Cost + N19*Inv_1_RO_Cost |

|

|

| |

We identify several

interesting cells in row 0 and row 1.

Cell |

Description |

I18 |

This cell holds the initial inventory

amount. It may be changed, as well as the other cells in

the initial rows of the model. |

H19 |

This cell is interesting because

it points several rows higher (earlier) in the simulation.

Cell H19 represents the replenishment amount received in

day 1 and points to the order quantity that occurred four

days earlier (in cell M15). We are assuming here that orders

are placed at the end of the day and are available for

sale three whole days later. The amount will be available

for sale during the fourth day following the order.

In general, expressions may point to any cell that describes

the system earlier in time. It is necessary to provide

one more initial row than the lead-time. Otherwise the

expression would point to a non-numerical cell.

Expressions may also point to cells in row 1. It is good

practice to only point to cells to the left in row 1. Otherwise

it is possible to create circular references. Excel does

not allow this. It is not reasonable to point to cells

lower (later) in the simulation. Circular references will

almost certainly be created. |

N19 |

This cell holds an "IF" expression,

that returns 1 if the inventory position in cell M19 is

less than the reorder point. Thus it indicates if an order

will be placed. |

O19 |

This cell holds an expression

that places the order quantity into the cell if the previous

cell, N19, is 1. |

T19 |

This cell computes the cost

per day based on the cost parameters and the decision to

order, the backorder amount and the inventory amount. Both

of the latter are computed at the end of the day. |

|

| |

By increasing the

sample size, the model can be simulated for a large number

of days to determine the average cost of operating the inventory.

The figure below shows the results of 1000 observations with

a reorder point of 75 and an order quantity of 150. A number

of rows and columns are hidden for clarity. Whenever the ending

inventory plus the amount on order is less than 75 and order

is placed. The order amount is 150.

At the top of the worksheet, the add-in has added summary

information about the simulation run. The cost of this policy is

$111 per week. To use the simulation for decision making, we

would vary the reorder point and order quantity to minimize

the total cost. Since the simulation is dynamic, this can be

done without rebuilding the model. |

|

| |

This model has been implemented

as the Inventory Game using the Control option.

The student observes the results at the end of each week and

makes real-time decisions regarding the inventory policy. |

| |

|

|