|

|

|

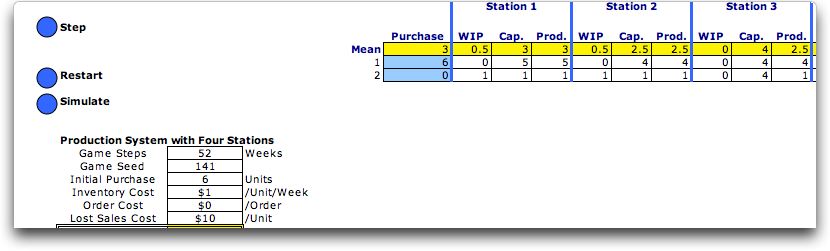

Simulation |

|

-

Production Model |

|

The production model is adapted

from a story in The Goal by Goldratt. We first describe

the story and then use the add-in to model the more general

sequential production process. The story involves three boy

scouts playing with matches. The game involves throwing dice

and passing matches from one boy to the next. The scoutmaster

is at the end of the line trying to light a fire with the matches

produced by the third boy.

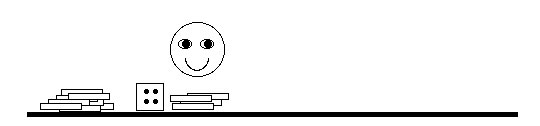

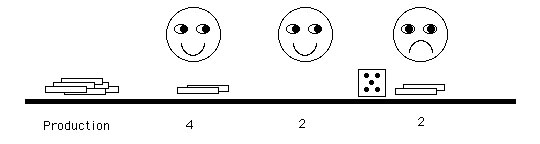

We start with a big pile of matches

to the left of the first boy. Boy 1 throws a single die. The

number showing is his production, so in this case the first

boy produces 4 matches. These matches are the raw materials

for the second boy.

The second boy throws the die. His production capability is

the amount shown on the die, but he can only produce as much

as available from the first boy. His production is the minimum

of his capability or the number remaining from the first boy.

There are 4 matches available, but the capacity of the second

boy is only 2. He passes these to the third boy, leaving 2

matches remaining. These two are called

work in progress (WIP).

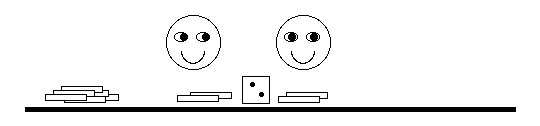

The raw materials for the third boy are the matches provided

by the second boy. Again, he produces the minimum on his die

or the matches available. For this case the capacity of the

third boy is 5, but only 2 matches are available as raw material.

The remaining 3 units of capacity are wasted. This is disappointing

to the third boy because his capacity was so much greater than

his production. There is no additional WIP.

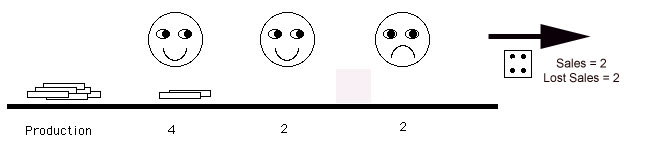

The scoutmaster has a demand that also depends on the throw

of the die. For the first iteration, the scoutmaster demands

4 matches. The third boy has only produced 2, so the scoutmaster

takes these two. The unsatisfied demand is lost. The

scoutmaster is disappointed with the third boy who seems to

be the bottleneck in this system.

In this first iteration, the system

produces 2 matches. Two matches remain in the system as WIP

waiting for processing by boy 2. This WIP has already been

processed by boy 1 and is available to boy 2 for processing

in the next iteration.

Goldratt told this story to illustrate the negative effects

of statistical variation on a serial production line. The simulation

model allows the system to have as many stations as desired

and the statistical variation to be governed by any of the

common probability distributions. |

The Excel Model |

| |

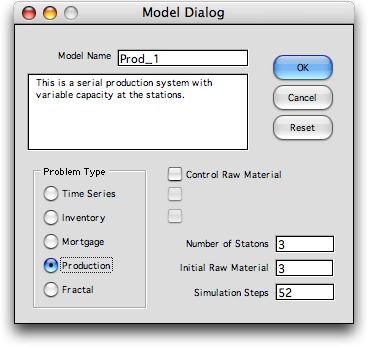

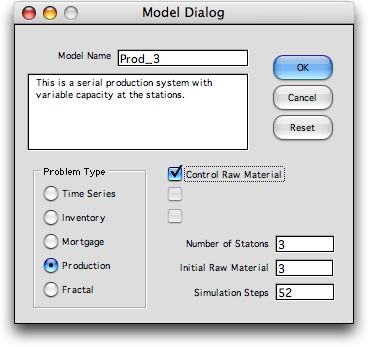

This story describes a serial

production system with a specified number of stations. To create

the model in Excel, click the Production button on

the model dialog. The

dialog has a field for Number

of Stations.

The checkbox adds a feature to the model that controls the

flow of raw material into the system. This is illustrated later.

The Raw Material

Supply field

is only relevant if this box is checked.

|

| |

After clicking OK, the multiline

dialog will be presented. Click OK. Then a series of dialogs

will be presented asking about the probability distributions

of the production amount at each stage. The uniform distribution

representing the throw of a single die is the default. The add-in

finally constructs a spreadsheet model of the multistage process.

We illustrate the features below. |

Parameters |

| |

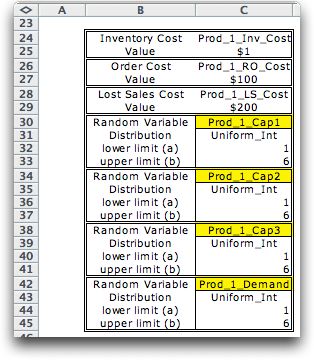

The cost parameters of the model

are below. We assume that an iteration reflects a one-week

interval. The first three entries are the cost parameters.

The inventory cost is the per unit cost of WIP per

week. The cost does not depend on the location of the WIP in

the process. The order

cost is

the cost of placing a nonzero order for raw materials. For

the example, this cost is expended

in every week. It is relevant when manual control of reorders

is controlled manually. The lost sales cost is the

unit cost of demand that is unmet by production.

We have chosen the integer-uniform distribution

for demand and production capacities. The integer-uniform distribution

models the throw of a die. |

Worksheet |

| |

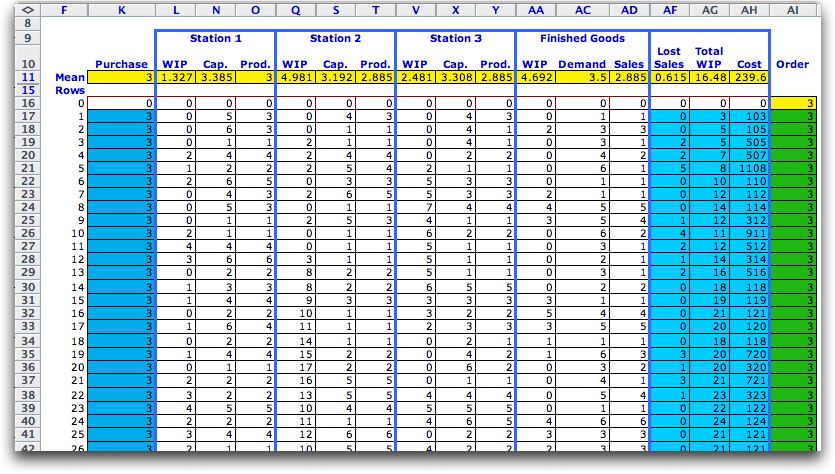

The worksheet illustrates

a three-station example. Station 1 accepts raw material, performs

its operation and then passes the material to station 2. Station

2 performs a second operation and then passes the material

to station 3. After the operation at station 3 the material

enters a finished good inventory. The demanded quantity is

withdrawn from this inventory. If demand is greater than the

amount available, lost sales are experienced. Because it has

so many columns we present the worksheet in two parts.

Columns G through J hold the random numbers that

govern the capacities for the three stations and the finished

good demand. Column K holds the materials purchased in each

week. For the example, the purchase amount is exactly the capacity

of the first station. The input capacity is unlimited.

|

|

| |

The station 1 information is outlined

in blue. We review the equations for period 1, row 17 on the

worksheet. Column L holds the input WIP. It is equal to the output

WIP of the previous period. Cell L17 holds a formula that is

"=P16". Since station 1 always produces its capacity, the WIP

is always 0. Column M holds the amount of material available

for production "=K17+L17".

Column N holds the capacity for production. This is a random

amount taken from the RN1 random variable "=RV_sim(Prod_1_Cap1,-G17)".

Column O holds the actual production, "=MIN(M17,N17)".

Column P holds the WIP available for the next period, "=M17-O17".

The results of station 1 are not too interesting, given that

it produces an amount equal to its capacity. Station 2 has more

interesting results. The formulas for station 2 are the same

as for station 1, but the columns references are advanced by

5.

The columns for station 3 and the finished goods inventory

are below. The formulas again are similar to stations 1 and

2. Columns AF compute lost sales, "=MAX(0,AC17-AD17)", total

WIP, "=L17+Q17+V17+AA17", and total cost, "=AG17*Prod_1_Inv_Cost+IF(K17>0,Prod_1_RO_Cost,0)+AF17*Prod_1_LS_Cost". |

|

| |

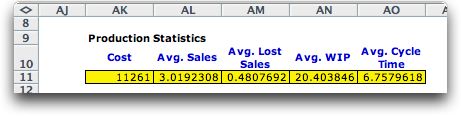

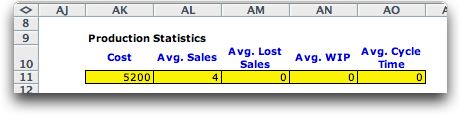

To the right of the station and

demand simulation we see summary results for the 52 weeks simulated.

Although the mean production capacity at each station is 3.5

per week, the average sales per week is just above 3. The average

demand is 3.5 per week, so the lost sales are about 0.5. The

average WIP per week is about 20.4. The average time required

for a match to move from station 1 to sales is the cycle time.

By Little's Law:

Cycle Time = WIP/Sales

For the example the average cycle time is

about 6.8 weeks.

The results indicate that the sequential production

process with statistical variability is not very efficient. The

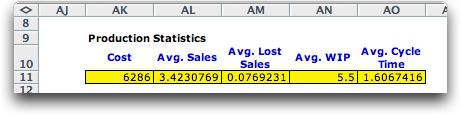

effect of reducing variability is illustrated when we change

the lower and upper limits on the uniform distributions to 3

and 4. The random variables have the same mean values but much

less variance. The system results shown below are much better.

With integer variables we cannot reduce the variability

to zero and maintain a mean value of 3.5 per week, but we can

set the lower and upper limits to 4. This eliminates variability,

and results in an average production rate of 4. When variability

is eliminated, lost sales, WIP and cycle time all go to zero.

In this model, the minimum cycle time is 0, because

material does not enter inventory if it passes through the system

in a single period. |

Controlling Raw Material Flow |

| |

One suggestion for controlling

a system such as this is to control the input flow of raw material.

This is an option available for the model. To investigate this

option click the Control Raw Material box.

With the control option a new column is included in the model

shown as column AI below. The column shown in green is the

order quantity that will be delivered in the next period. When

the worksheet is created this column has zero's except for

the yellow entry at the top. We have filled in the column with

the value 3. This puts a steady flow of 3 units into the system

at each period. |

|

| |

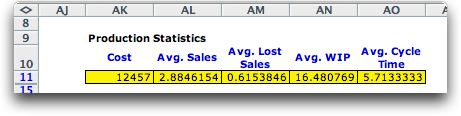

The results of the 52-week simulation

are below. Since the average demand is 3.5, there will be lost

sales. Because of statistical variability there is still a

considerable amount of WIP and cycle time is greater than the

minimum value of 0.

|

| |

The control column is very general

in that order quantities can be entered by hand or with formulas.

There are a number of questions one might explore with this model.

- What is the effect of reducing the variability of the production

capacities?

- What is the effect of having more production stations?

The model allows the analysis of any number of stages.

- If one were to add more capacity, would be better at the

beginning of the line or at the end? Capacity is added by

increasing the upper range on the uniform distribution.

- Can a similar simulation be constructed for a pull system

of production, rather than the push system illustrated here?

- Using the control column, how would you model a CONWIP

inventory policy? This policy orders raw materials in exactly

the amounts sold in each period. The WIP remains constant

at the initial value throughout the simulation.

- Would it be useful to adopt an order level-order quantity

policy? In some periods the order quantity could be zero,

thus reducing the reorder cost.

|

The Game |

| |

The control option is built into

the Production

Game provided as a template in the Template section

of this site.

The game reveals the situation one week at a time. The student

fills in the order quantity during each period. The goal of the

game is to select order quantities to minimize the total cost

of operating the system. |

|

| |

|

|