|

|

>  |

Teach

Dynamic Programming Add-in

|

|

|

|

|

Many operational problems in manufacturing,

service and distribution require the sequencing

of various types of activities or items. Examples

include a production facility in which chassis

must be sequenced through an assembly

line, an express mail service where parcels

and letters must be routed for delivery, and

a utility company that must schedule repair

work. In

this section, we introduce a robust dynamic

programming formulation that can be used

to tackle a number of such problems. In

most cases, however, the size of the state

space is an exponential function of the number

of items being sequenced.

To choose a sequencing problem select the Sequencing option

button on the Problem Definition dialog.

Choose a name for the model and specify whether

to maximize or minimize the objective. Specify

the number of items to be sequenced.

We discuss the data form option after the

model is described below.

|

|

| |

As a prototype, consider the problem of sequencing

a set of n jobs through a single machine that can

work on only one job at a time. Once a job is started,

it must be completed without preemption. The time required

to process job j once the machine begins to work on

it is p(j) for j = 1,...,n. The

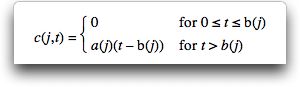

associated cost c(j,t) is a function

of its completion time t and can take a variety of

forms, the simplest being

c(j,t) = a(j)t where a(j)

is the cost per unit time for job j. This form

admits a very simple solution when the objective is to minimize

the total completion cost of all the jobs. The optimum

is obtained by computing the ratio p(j)/a(j) for

each job and then sequencing them in order of increasing values

of this ratio. The job with the smallest ratio is processed

first, the job with next smallest ratio is processed second,

and so on until all jobs are completed. Ties may be broken

arbitrarily.

A much more

difficult problem results when each job j has a due

date b(j). The

cost of a job is zero if it is completed before its due date

but increases linearly if it is tardy. In our models, a(j)

is referred to as the penalty for a late job.

The goal of the optimization is to determine the sequence

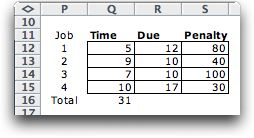

that has the smallest total cost. The table gives

the relevant parameters for a 4-job instance.

There are 4!

= 24 possible solutions. For the solution (3, 1, 2, 4),

the completion times are 7, 12, 21 and 31 respectively. Jobs

3 and 1 are completed before their due date so no cost is incurred. Job

2 is 11 days late resulting in a cost of $440 and job 4 is

14 days late resulting in a cost of $420. The total cost

is therefore $860. |

Returning to the Problem Definition Dialog |

| |

The problem definition dialog at the top of

this page has various options for specifying data forms for

the sequencing problem. When the Make Random Problem box

is checked, the random selects data to create interesting

problems. The DP model of the sequencing problem is

robust regarding the model for the objective function. We try

to illustrate this with the various data forms provided.

The data in the table for the example shows columns for time,

due date and penalty. The amount of data included in the table

depends on the Data

Form entry

on the problem definition dialog. The table above is data form

1. It assumes that the job penalty is constant with the number

of days late. If we had chosen data form 0, the penalty column

is not included. The jobs are assumed to have equal late

penalties of 1. With data form 2, a matrix is constructed

to show the late penalty as a function of the number of days

late. This would be useful when the late penalties are nonlinear

with time. The number of columns in this matrix is equal

to the total of the job times assigned during the generation

process. For the example that number is in cell Q15, so a

table with 31 columns would be constructed for data

form 2. If the number of columns is more than those available

on the worksheet, you will receive an error message.

The initial worksheet constructed depends on whether the Make

Random Problem box is checked on the dialog.

The Max Time entry provides an upper

bound to the job times when the Make Random Problem is

checked. With the default value of 10, all job times are

less than or equal to 10 as in the example. Using other maximum

time entries results in problems with greater time variety.

With the random option, due dates are are randomly selected

using the total job times as an upper bound. That sum

is calculated immediately below the time column. Even when

the Make Random Problem box is not checked,

the jobs are assigned random due times. Any numbers placed on the

data table by the add-in generation process can be replaced by

the user.

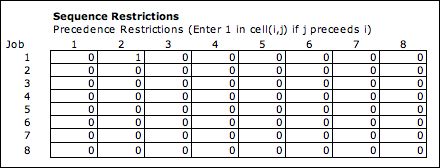

When the Sequence Restrictions box is checked, a table

is included on the worksheet to restrict the order of the sequence.

The table below shows a problem with eight jobs. The 1 in cell

(1,2) requires that job 2 precede job 1 in the sequence. Restrictions

such as these are easy to incorporate in the DP algorithm and

actually

make the problem

simpler.

|

DP Model |

| |

|

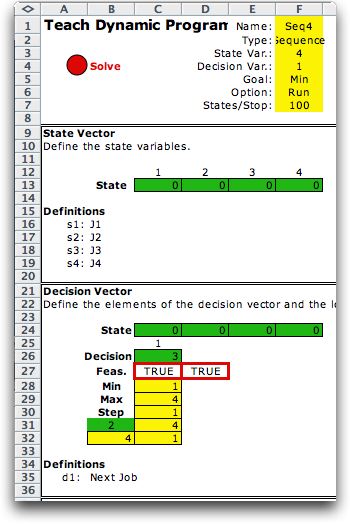

The add-in automatically creates

the model that solves the DP for a given number of jobs.

You can see the model by creating an example with the TeachDP

add-in or by looking at the example workbook for this section

(Worksheet Seq4 in teachdpdem.xls). The figure at the left

shows the state and decision vectors for the model

example.

The model requires a

state variable for each position in the sequence. The state

defines the set of jobs that are already scheduled. There

is a single decision variable that is the index of the

next job to schedule.

|

|

Solving the Problem |

| |

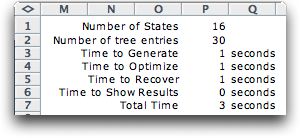

Clicking the Solve button

solves the problem. The solution statistics are below. The

program first generates the states. Since there are four binary

state variables, there are 16 states in the exhaustively generated

set.

The figure below shows the decision network for

the example. Each node represents a state. Each arc represents

a decision that leads from one state to another. Since a state

indicates the set of completed jobs, the finish time of the set

can computed as the sum of the job times for the jobs in the

set. Given the

state, the cost of adding a job to the set can be computed and

assigned to the decision arc. The DP solver has the problem of

finding the shortest path through the decision network from some

initial state to a final state. The heavy lines in the figure show

the arcs and nodes on the optimum path. The path starts at the

initial state

(0,0,0,0) and ends

at the

final state (1,1,1,1). |

| |

|

| |

The DP solution algorithm works

backwards starting from (1,1,1,1). It firsts finds the optimum

decision from each of the states with three 1's. These decisions

are trivial. For example, there is only one way to go from

(1,1,1,0), and that is J4. The cost

of J4 leading from (1,1,1,0) to (1,1,1,1) is 420. We assign

that value to state (1,1,1,0). Retreating to the states with

two 1 entries, there are two possible decisions. The optimization

finds the one that yields the smallest value. For example,

from state (1,0,1,0), J2 and J4 are the decisions. Given

the data the optimum is J2 with a cost of 440. It leads to

(1,1,1,0). Continuing with the states with only one entry with

value 1, each state has three decisions. All must be evaluated

to find the optimum at each state. For the example, we find

that from state (0,0,1,0) the optimum is J1. The cost associated

with that decision is 0 because J1 is completed on time. There

are four feasible decisions leading from (0,0,0,0). The optimum

is J3 leading to state (0,0,1,0).

At the completion of the solution process, we have for each

state the optimum decision and the optimum cost to reach the

final state. One last process is required. |

Recovering the Optimum |

| |

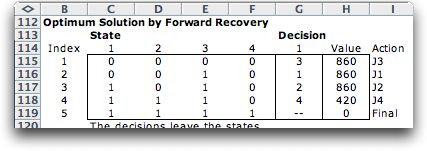

After the DP process is complete, we can find

the optimum from any state to the final state. Since we have

only one initial state, (0,0,0,0), we will find

the path from (0,0,0,0) to (1,1,1,1). The process is called recovering

the optimum.

State (0,0,0,0) has the optimum decision J3.

The value associated with (0,0,0,0) is 860, the length of

the path to (1,1,1,1). We record this as the first row of our

solution matrix. The decision leads to state (0,0,1,0), where

the optimum decision is J1 with cost of 860. It is the same

as (0,0,0,0) since the cost of J3 is 0. This leads to state

(1,0,1,0) where the value is again 860. Decision J2 with a

cost of 440 then leads to (1,1,1,0). The value at this state

is 420, the cost of the last decision J4. The last state has

no more decisions, so this is the final state. The optimum

sequence starting from the initial state is: J3, J1, J2 and

J4 with a total cost of 860.

The Options command under the Teach

DP menu allows various output alternatives to view the details

of the DP process.

|

Summary |

| |

Although DP is quite efficient for

small problems, the number of states grows exponentially with

the number of jobs. This 4 job example has 16 states, a five

job problem has 32 states, and in general the number of states

is 2 raised to the power of the number of jobs. |

| |

|

|