| |

In this section we consider

the push/network process. Many of the definitions and computations

associated with the various drive/structure alternatives are

the same as for the push tree. The principal changes are in the

data defining the network structure and the proportions. The

computation of the unit flows is quite different for the network

structure as compared to the tree structure. |

| |

Push/Network

Process

Figure 1

|

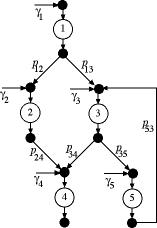

The

push/network process is illustrated in Fig. 1. For this

structure the flow through each operation may go to more

than one operation, and each operation may have several

input flows from other operations. This is a more general

structure than the push/tree process. Product is inserted

or pushed into any of the operations. We use  as

the amount pushed into operation i. We assign

the value of 1 to  .

The push flows to the other operations are given as relative

to  .

Indices are assigned to the operations arbitrarily, however,

it is often convenient to assign the indices to be increasing

in the direction of primary product flow.

For the push network we identify the proportion,  ,

as the amount of the output of operation i that

is passed to operation j for each unit of product

passing through operation i. The value of ,

as the amount of the output of operation i that

is passed to operation j for each unit of product

passing through operation i. The value of  may

be any nonnegative amount. Typically for a service system,

the sum of the proportions leaving an operation is equal

to 1. This means that the flow is split among the several

following operations. It may be necessary to use other

combinations of proportions to represent different systems. may

be any nonnegative amount. Typically for a service system,

the sum of the proportions leaving an operation is equal

to 1. This means that the flow is split among the several

following operations. It may be necessary to use other

combinations of proportions to represent different systems.

The example shows an arc passing from operation 5 back

to operation 3. In a practical instance, this might represent

the reworking of some part.  as

the proportion of the output of operation 5 returned to

operation 3. It is not necessary to define a proportion

for the flow leaving the system at operation 5. as

the proportion of the output of operation 5 returned to

operation 3. It is not necessary to define a proportion

for the flow leaving the system at operation 5.

|

|

Tabular

and Matrix Representation |

| |

Figure 2

|

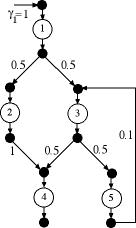

We use Fig. 2 as a numerical example.

Here we push 1 unit into operation 1 and nothing into

the other operations.

Although we can represent much of the data for a push

network with a two-dimensional table as illustrated for

the example below, it is necessary to represent the proportions

on a square matrix. We call this the proportion matrix P.

Notice that we have left out both the Previous and Proportion columns

from the table since the following preceding operation

is not unique for the network. The matrix P describes

both preceding operations and proportions.

For the example, we assume zero scrap rates and grouping

factors equal to 1. |

|

|

|

| Name |

Index |

Push

In |

Scrap |

Group |

| Op.

1 |

1 |

1 |

0 |

1 |

| Op.

2 |

2 |

0 |

0 |

1 |

| Op.

3 |

3 |

0 |

0 |

1 |

| Op.

4 |

4 |

0 |

0 |

1 |

| Op.

5 |

5 |

0 |

0 |

1 |

For the push network structure we define the following notation.

We use i for the general operation index.

= the flow pushed into operation i.

= the flow pushed into operation i.  = the proportion of flow that is scrapped or removed at operation

i.

= the proportion of flow that is scrapped or removed at operation

i. = the number of items grouped at operation i.

= the number of items grouped at operation i. = the proportion of the output of operation i that

is sent to operation j.

= the proportion of the output of operation i that

is sent to operation j. = the time required for one unit to pass through operation

i. (not shown in the table)

= the time required for one unit to pass through operation

i. (not shown in the table)

For the network, flow may pass from an operation to any other

operation, so a matrix is required to describe the proportion

information. We call the matrix P. In general

For the case of the example:

The Excel model created by the Process Flow add-in

is shown below. The add-in adds dummy operations 0 and 6. Indices

are automatically assigned by the add-in, as indicated by the

green field. The Previous column is not required. The

Push In column shows 1 unit pushed into operation 1.

We have indicated arbitrary times in the Operation Time

column. Since the Scrap Rate and Group Factor

are 0 and 1 respectively, we have not included their columns.

No Proportion column is necessary for a network. |

| |

|

|

The structure

and proportions are described by the P matrix

(Transfer Out matrix). This matrix is on the left of

the figure below and includes the dummy operations 0 and 6.

The matrix on the right is called the Augmented Matrix.

Proportion data is entered in the P matrix,

and the Augmented Matrix is determined by Excel formulas. The

two matrices are constructed on the same rows of the Excel worksheet

as the tabular data for the process. |

|

Scrap and Flow Removed |

| |

These features take the

default values, 0 and 1, respectively. They do not affect the

analysis. Nontrivial values would be handled in the same way

as the push/tree structure. |

Grouping, Flow Removed

and Flow Ratio |

|

|

The general expression

for the flow ratio is:

Using the example parameters all ratios are 1,

as shown in column F. The column designations provided in this

discussion (F) refer to the example worksheet above. The column

designations for a different instance will depend on the location

of the process on the worksheet. |

Unit Flow |

| |

Figure 3 |

To illustrate

the computation of the unit flows we use an example with

three operations as in Fig. 3. The value of  ,

the input flow to operation i depends on the push

flow at operation i and the amounts provided by

the preceding operations, j and k. ,

the input flow to operation i depends on the push

flow at operation i and the amounts provided by

the preceding operations, j and k.

We write the equations entirely in terms

of the unit flows by using the flow ratios.

This generalizes to the expression that

must hold for each operation.

We define the augmented proportion matrix as

Also define the column vector u of

unit flows. Then the unit flows are the solution to the

linear set of equations:

The T superscript indicates the matrix transpose

operation.

For the example, the matrices are:

Note that the proportions leaving operation i are

described by row i of the P matrix.

Solving for the unit flows we find:

The unit flow vector is computed using Excel

matrix operations and is shown in column G of the example

worksheet. |

|

Unit Time |

|

|

The time required for operation i per

unit of finished product is called the unit time and designated

. .

This computation is the same for all drive/structure

alternatives and is stored for the example in Column H. The

sum of the unit times is the Throughput time.

It is computed and stored in cell K44.

|

Operation Flow |

|

|

Again, this computation is the same for all

drive/structure alternatives. The illustration assumes there

the operating inverval is hours and the demand interval is

weeks with 40 hours used per week.

The value of V is from cell B46 in

the example. The denominator of the expression depends on

the time units selected for the demand and operation intervals.

It is entered in cell G45. The computed values are placed

in column I of the worksheet.

|

Work-in-Process (WIP) |

|

|

This computation is

the same for all drive/structure alternatives.

The sum of operation WIP values is computed and

stored in cell K45. |

| |

|