| |

In this section we consider

the push/tree process. Many of the definitions and computations

associated with the various drive/structure alternatives are

the same as for the pull/tree. We limit our discussion to those

aspects that are different. The principal changes are in the

data defining the tree structure, the definition of the proportion

parameter and the computation of the unit flow. |

| |

Push/Tree

Process

Figure 1

|

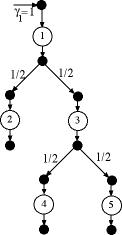

The generic push/tree process is illustrated

in Figure 1. For this structure the flow through each

operation comes from a unique preceding operation, while

each operation may have several output flows to other

operations. Product is inserted or pushed into the operation

with the smallest index, operation 1 for the example,

in the amount  .

We usually assume that this amount is 1. In addition to the initial operation of the process, our

models also allow flow to be pushed into the other operations.

These products entering the system at intermediate points.

In general, we identify the amount pushed into the input

of operation i as  ,

the push flow at operation i. ,

the push flow at operation i.

For tree structures we require that the operations be

indexed so that when flow passes from operation i to

operation j, i < j.

For the push tree we identify the proportion,  ,

as the proportion of the output of operation i that

is sent to operation j. The value of ,

as the proportion of the output of operation i that

is sent to operation j. The value of  may

be any positive amount to represent a variety of manufacturing

situations. may

be any positive amount to represent a variety of manufacturing

situations. |

|

Tabular

Representation |

| |

Figure 2

|

We use Fig. 2 as a numerical example.

Here we push 1 into operation 1 and nothing into the

other operations.

For this illustration, we are assuming that 10% of the

units passing through each operation are scrapped. We also

assume proportions of 0.5 for operations 2 through 5. This

means that operation 1 sends half of its output to each

of operations 2 and 3. Further, operation 3 sends half

of its output to each of operations 4 and 5. Units are

removed from the operations with no successor operations

in the amounts required to fulfill the pushed input flows. |

|

|

|

We represent the data

for the example push tree with a two-dimensional table as illustrated

below. Here we provide only the columns necessary to show the

tree structure and compute flows. Later we add other operational

data.

| Name |

Index |

Previous |

Push

In |

Scrap |

Group |

Proportion

|

| Op.

1 |

1 |

0 |

1 |

0.1 |

1 |

1 |

| Op.

2 |

2 |

1 |

0 |

0.1 |

1 |

0.5 |

| Op.

3 |

3 |

1 |

0 |

0.1 |

1 |

0.5 |

| Op.

4 |

4 |

3 |

0 |

0.1 |

1 |

0.5 |

| Op.

5 |

5 |

3 |

0 |

0.1 |

1 |

0.5 |

For the push tree, an operation can obtain its input from no

more than one other operation, so the column labeled Previous

is sufficient to describe the tree structure. The column labeled

Proportion gives the proportion of the output of the

previous operation that is sent to the operation. The number

(0.5) in the row for Op. 2, holds the value of  . .

For the push/tree structure we define the following notation.

We use i for the general operation index.

-

= the index of the operation preceding (or before) operation

i. This is the number in the Previous column.

= the index of the operation preceding (or before) operation

i. This is the number in the Previous column.

= the flow pushed into the input of operation i.

= the flow pushed into the input of operation i.  = the proportion of flow that is scrapped or removed at operation

i.

= the proportion of flow that is scrapped or removed at operation

i. = the number of items grouped at operation i.

= the number of items grouped at operation i. = the proportion of the output of operation

= the proportion of the output of operation  that is sent to operation i.

that is sent to operation i. = the time required for one unit to pass through operation

i. (not shown in the table)

= the time required for one unit to pass through operation

i. (not shown in the table)

We use the symbol b as the first subscript on  to indicate that it is the proportion of the output of the preceding

operation that is sent to operation i. When an operation

has no preceding operation we assign the value 0 to

to indicate that it is the proportion of the output of the preceding

operation that is sent to operation i. When an operation

has no preceding operation we assign the value 0 to  ,

and ,

and  has no effect.

has no effect.

The Excel model created by the Process Flow add-in

is shown below. The add-in adds dummy operations 0 and 6. Indices

are automatically assigned by the add-in, as indicated by the

green field. The Previous column represents the tree

structure of Fig. 1. The Push In column shows 1 unit

pushed into operation 1. We have indicated arbitrary times in

the Operation Time column. The Scrap Rate,

Group Factor and Proportion columns are filled

with the data specified for the example. |

|

|

|

The columns

starting with J are computed using formulas inserted by the

add-in. Our purpose in this section is to provide the derivation

of these formulas for the push/tree process. |

Scrap and Flow Removed |

|

|

This is the same as the

pull/tree structure. |

Grouping, Flow Removed

and Ratio |

|

|

The computations are

the same as for the pull/tree structure.

The example shows the flow ratios in the columns

labeled Ratio (K). Since all scrap rates are 0.1 and

all grouping factors are 1, all ratios are 0.9. |

Unit Flow |

| |

Figure 3 |

For operation i in

Fig. 3, the value of  is

entirely dependent on the push flow added at operation i and

the amount passed from operation j. Since the

amount from operation j is is

entirely dependent on the push flow added at operation i and

the amount passed from operation j. Since the

amount from operation j is  we

have the relation between the unit flows at i and j. we

have the relation between the unit flows at i and j.

Notice that the unit flow for an operation

depends on the unit flow of its unique preceding operation.

For the push/tree process, the unit flows can be computed

recursively, starting with the  and

continuing for each operation with sequentially increasing

operation index. The results for the example are shown

in the Unit Flow column (L) of the Excel display.

Notice the unit flow through operation 5 is 0.2025. This

means that for 1 unit of product introduced at operation

1, 0.2025 units must pass through operation 5. If the scrap

rates were zero, all ratios would have been 1, and the

unit at flow operation 5 would have been entirely determined

by the proportions. The unit flow at operation 5 would

have been 0.25 in this case. and

continuing for each operation with sequentially increasing

operation index. The results for the example are shown

in the Unit Flow column (L) of the Excel display.

Notice the unit flow through operation 5 is 0.2025. This

means that for 1 unit of product introduced at operation

1, 0.2025 units must pass through operation 5. If the scrap

rates were zero, all ratios would have been 1, and the

unit at flow operation 5 would have been entirely determined

by the proportions. The unit flow at operation 5 would

have been 0.25 in this case. |

|

Unit Time |

|

|

The computations are the same as for the pull/tree

structure. The results are shown in column M. The sum of the

operation unit time values is the total time in the system

for each unit entering node 1. For a serial system, this is

the cycle time for the product. In the more general context

we call it the throughput time. This sum is computed and stored

in cell K16.

|

Operation Flow |

|

|

The computations are the same as for the pull/tree

structure. The results are shown in column N.

|

Work-in-Process (WIP) |

|

|

The computations are

the same as for the pull/tree structure. The results are shown

in column O.

The sum of the operation WIP values is the average

WIP of the entire process. This sum is computed and stored in

cell K17. |

| |

|