|

|

|

Process

Flow Analysis |

|

- Drive/Structure

In this section we recognize two structure alternatives, tree

and network, and two drive alternatives, pull and push. To find

the flows in the operations of a process, the structure of the

process and the driver of the flows must be specified. We review

the four possibilities on this page. More detailed pages are

reached through the links on the titles.

|

|

The structure and drive

options are set with buttons on the Add Process dialog.

The structure determines the arrangement of the flow paths in

the operations chart. A tree either starts with a single raw

material and the flow diverges to produce multiple products,

or starts with several raw materials and the flow converges

to produce a single product. A network allows an arbitrary interconnection

between operations.

The drive option specifies the cause of flow through the process.

For the pull option, products are pulled from the outputs of

operations. For the push option, items are pushed into the inputs

of the operations. |

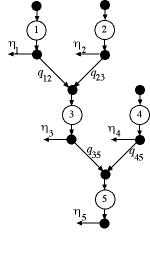

Figure 1

|

The generic pull/tree process is illustrated in Figure 1. For

this structure the flow through each operation goes to a unique

following operation, while each operation may have several input

flows from other operations. This structure is appropriate for

modeling many manufacturing processes where raw materials are

combined or mixed to produce a single product. Product is withdrawn

or pulled from the operation with the greatest index, operation

5 for the example, in the amount  .

For analysis purposes we will usually assume that this amount

is 1, so we can compute the flow through each operation per

unit of finished good.

In addition to the final operation of the process, our models

also allow flow to be pulled from the other operations. These

flows represent intermediate products. In general, we identify

the amount pulled from the output of operation i as

,

the pull flow at operation i. ,

the pull flow at operation i.

For the tree structures we require that the operations be indexed

so that when flow passes from operation i to operation

j, i < j. The greatest index is

m. For the example m is 5.

For the pull tree, we identify  as the amount of the output of operation i required

for each unit of product passing through operation j.

The value of

as the amount of the output of operation i required

for each unit of product passing through operation j.

The value of  may be any positive amount to represent a variety of manufacturing

situations. An assembly operation that requires one unit of

each input to be combined to produce one unit of a subassembly

would have the proportions equal to 1 for each input. A mixing

operation that combines inputs into a mixture would have input

proportions that sum to 1. An operation that requires more than

one unit of some input would be modeled with a proportion greater

than 1 on the associated input.

may be any positive amount to represent a variety of manufacturing

situations. An assembly operation that requires one unit of

each input to be combined to produce one unit of a subassembly

would have the proportions equal to 1 for each input. A mixing

operation that combines inputs into a mixture would have input

proportions that sum to 1. An operation that requires more than

one unit of some input would be modeled with a proportion greater

than 1 on the associated input. |

|

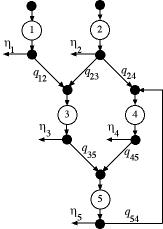

Figure 2 |

The generic push/tree

process is illustrated in Fig. 2. For this structure the flow

into an operation comes from a unique preceding operation, while

the operation may have several output flows going to other operations.

This structure is appropriate for modeling service systems where

customers arrive at a source node, node 1 in the example in

the amount  .

We call the items entering the system, units of product. In

addition to node 1, products may also be pushed into the network

at other operations. The flow entering at operation i

is .

We call the items entering the system, units of product. In

addition to node 1, products may also be pushed into the network

at other operations. The flow entering at operation i

is  .

Note that push flow enters the process just before an operation. .

Note that push flow enters the process just before an operation.

The flow that passes through an operation may be split to go

to other operations to receive different types of processing.

Units pass through the tree until finally they are withdrawn

at the nodes that have no successors, nodes 2, 4 and 5 in the

figure. For analysis purposes, we will usually assume that  = 1 and that all other

= 1 and that all other  are zero, so that we can compute the flows passing through the

operations per unit of flow entering node 1. We call these amounts

the unit flows.

are zero, so that we can compute the flows passing through the

operations per unit of flow entering node 1. We call these amounts

the unit flows.

For the tree structures we require that the operations be numbered

so that when flow passes from operation i to operation

j, i < j. The greatest index is

m. For the push tree, we identify  as the proportion of the output of operation i that

is passed to operation j. The value of

as the proportion of the output of operation i that

is passed to operation j. The value of  may be any positive amount to represent a variety of manufacturing

situations. For a splitting operation that separates the total

flow passing through operation i into several paths,

the sum of the proportions leaving i would equal 1.

may be any positive amount to represent a variety of manufacturing

situations. For a splitting operation that separates the total

flow passing through operation i into several paths,

the sum of the proportions leaving i would equal 1. |

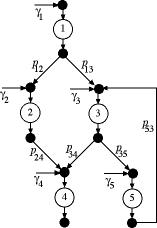

| Pull/Network

Process

Figure 3 |

The pull/network process is illustrated in Fig. 3. For this structure

the flow through each operation may go to more than one operation,

and each operation may have several input flows from other operations.

This is a more general structure than the pull/tree structure.

Product is withdrawn or pulled from any of the operations. Again

we use  as the amount pulled from operation i. With m

operations we assign the value of 1 to

as the amount pulled from operation i. With m

operations we assign the value of 1 to  .

The pull flows from the other operations are given as relative

to .

The pull flows from the other operations are given as relative

to  .

Indices are assigned to the operations arbitrarily, however, it

is often convenient to assign the indices to be increasing in

the direction of primary product flow. .

Indices are assigned to the operations arbitrarily, however, it

is often convenient to assign the indices to be increasing in

the direction of primary product flow.

For the pull network, we identify  as the amount of the output of operation i required

for each unit of product passing through operation j.

The value of

as the amount of the output of operation i required

for each unit of product passing through operation j.

The value of  may be any nonnegative amount to represent a variety of manufacturing

situations. An assembly operation that requires one unit of

each input to be combined to produce one unit of a subassembly

would have the proportions equal to 1 for each input. A mixing

operation that combines inputs into a mixture would have input

proportions that sum to 1. An operation that requires more than

one unit of some input would be modeled with a proportion greater

than 1 on the associated input.

may be any nonnegative amount to represent a variety of manufacturing

situations. An assembly operation that requires one unit of

each input to be combined to produce one unit of a subassembly

would have the proportions equal to 1 for each input. A mixing

operation that combines inputs into a mixture would have input

proportions that sum to 1. An operation that requires more than

one unit of some input would be modeled with a proportion greater

than 1 on the associated input.

The example shows an arc passing from operation 5 back to operation

4. In a practical instance, this might represent the reworking

of some part. Although we might be tempted to identify  as the proportion of the output of operation 5 returned to operation

4, this is not correct for a pull network.

as the proportion of the output of operation 5 returned to operation

4, this is not correct for a pull network.  is the proportion of the flow through operation 4 that comes

from operation 5. Similarly,

is the proportion of the flow through operation 4 that comes

from operation 5. Similarly,  is

the proportion of the flow through operation 4 that comes from

operation 2. is

the proportion of the flow through operation 4 that comes from

operation 2. |

| Push/Network

Process

Figure 4 |

The push/network process is illustrated in Fig. 4. For this structure

the flow through each operation may go to more than one operation,

and each operation may have several input flows from other operations.

This is a more general structure than the push/tree process. Product

is inserted or pushed into any of the operations. We use  as the amount pushed into operation i. We assign the

value of 1 to

as the amount pushed into operation i. We assign the

value of 1 to  .

The push flows to the other operations are given as relative to .

The push flows to the other operations are given as relative to

.

Indices are assigned to the operations arbitrarily, however, it

is often convenient to assign the indices to be increasing in

the direction of primary product flow. .

Indices are assigned to the operations arbitrarily, however, it

is often convenient to assign the indices to be increasing in

the direction of primary product flow.

For the push network we identify  as the amount of the output of operation i that is

passed to operation j for each unit of product passing

through operation i. The value of

as the amount of the output of operation i that is

passed to operation j for each unit of product passing

through operation i. The value of  may be any nonnegative amount. Typically for a service system,

the sum of the proportions leaving an operation is equal to

1. This means that the flow is split among the several following

operations. It may be necessary to use other combinations of

proportions to represent different systems.

may be any nonnegative amount. Typically for a service system,

the sum of the proportions leaving an operation is equal to

1. This means that the flow is split among the several following

operations. It may be necessary to use other combinations of

proportions to represent different systems.

The example shows an arc passing from operation 5 back to operation

3. The value of  is the proportion of the output of operation 5 returned to operation

3. In a practical instance, this might represent the reworking

of some part. It is not necessary to define a proportion for

the flow leaving the system at operation 5.

is the proportion of the output of operation 5 returned to operation

3. In a practical instance, this might represent the reworking

of some part. It is not necessary to define a proportion for

the flow leaving the system at operation 5. |

|

|