|

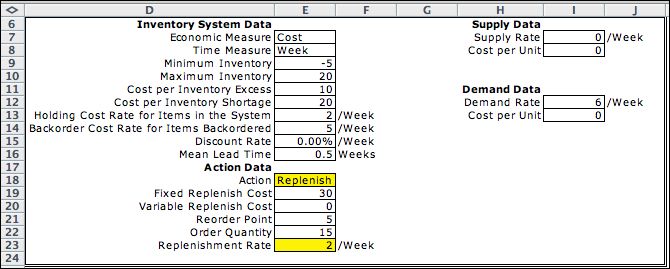

The CTMC data is quite similar

to the DTMC except that a step size is not specified and values

that depend on the step size are not computed. The cell formerly

holding the step size now holds a parameter called mean

lead time. The lead time is the time between when a replenishment

order is placed and when the order quantity is delivered into

inventory. The other models assume a fixed lead time of one

step, 0.5 weeks in our example. For the CTMC the lead time

is a random variable that has an exponential distribution with

a mean of 0.5 weeks.

For the CTMC all the event components are random

variables with exponential distributions. This is consistent

with the demand over a finite interval having a Poisson distribution,

as assumed by the other models. Time is continuous and a transition

occurs only when an event occurs. Two or more events

cannot occur at the same time. In the inventory model there

are only three event components: an arrival when a unit of

supply arrives, a departure when a unit of demand arrives,

and a replenishment when the lot (or order quantity) is delivered.

Since the supply rate for the example is 0, the supply event

never occurs. The demand rate is 6 per week, so the mean time

between demand events is 1/6. The mean replenishment time

is 0.5 weeks, so the mean replenishment rate is 2 per week. |

The Model |

|

The model for the CTMC is quite

different than the models using the fixed step size. The state

variable now has two dimensions. The first state variable is

the stock level. The second state variable is binary. The value

of 1 indicates that a replenishment order has been placed and

the value of 0 indicates that no order is outstanding.

The event has three components, one for supply, one for demand,

and one for replenishment. Each has two possibilities, 0 and

1. The value 1 indicates that the associated event

has occurred, while a 0 indicates that it has not. The feasibility

cell K17 has a logical expression:

=SUM(CTMC_DPM_Event)=1

This means that exactly one of the components is equal to

1 when an event occurs. The example shows the occurrence

of the demand event. The current stock level is 3 and a replenishment

order is outstanding. |

|

| |

An event signals a transition, and the transition

blocks determine the new state, the cost of transition and

the rate of transition. The first block represents the delivery

of a replenishment order. This transition is possible

only when there is an outstanding order (the second state variable

is 1) and the event indicates a replenishment.

The second transition describes the process of placing an

order. An order is placed whenever there is no outstanding

order and the stock level is less than or equal to the reorder

point (5 for the example).

The third transition describes a simple unit supply or demand.

This transition is feasible for the given state and event and

the transition prescribes a transition to state (2, 1). The

rate of the transition is 6 and its cost is 0. |

|

Lists |

| |

The enumeration process creates the state

list, event list and transition list. |

| |

|

The state list is generated by

sequencing all possible values of the state counter E14.

There are 52 states with the parameters specified on the

Data worksheet. |

|

| |

|

The event list has only three

entries. |

|

| |

|

When all feasible states are

enumerated with all feasible events, 72 transitions are

discovered. Transitions with 0 rate are not listed and

we see no events with supply. |

|

Markov Analysis |

| |

|

The Markov Analysis add-in

is the only solution alternative for the CTMC. On transferring

the lists to that program we find that many of the states

are transient for the data parameters given.

A variety of analyses are possible with the add-in, but

there are too many states to obtain steady-state results. |

|

Summary |

| |

The CTMC model is interesting because it is

so different than the DTMC model. It includes a state variable

indicating whether a replenishment has been ordered. This suggests

a way to handle a fixed lead time (other than 1) in the other

models. The new model would have a state variable that counts

the number of steps since the replenishment order. When that

state variable reaches the lead time, the replenishment would

be delivered. We leave this as an exercise for the student. |

| |

|