|

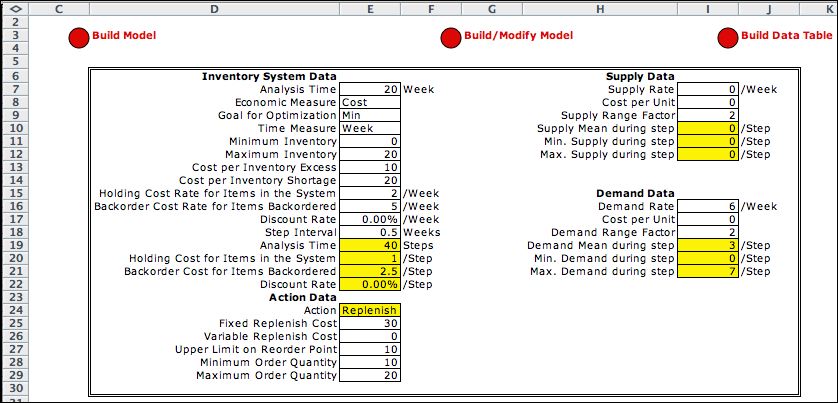

The data below shows the

parameters of our example problem. Note that the supply rate

is specified as zero while the demand rate is 6. This is typical

of inventories where product is withdrawn at random times and

replenished when necessary. The costs of demand and supply

are both zero. The total cost used by the analysis

is an estimate of the inventory operating cost.

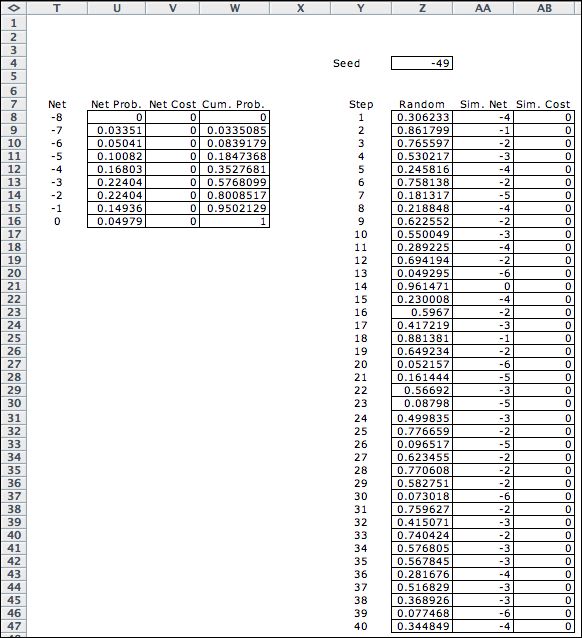

The distribution of the demand is shown in columns U and V.

The random variables are negative indicating that demand draws

material out of the inventory. The deterministic model uses

net demand simulated from this distribution. The simulated

values are linked to a random number seed entered in cell Z5.

A different simulated sequence is obtained with a different

seed.

|

| |

The demand expressed as positive

quantities is shown in the chart below. The deterministic DP

problem is to find a sequence of replenishments to meet this

demand that minimizes total cost. |

|

|

| |

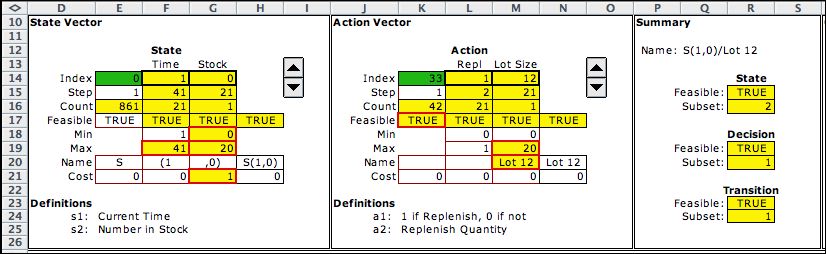

We create the model by clicking the Build

Model button at the top of the data worksheet. A new worksheet

is created with the name DDP_Model. The DDP has only

states and actions. For the DDP demand is not a random

variable but a simulated value for each of the 40 steps of

the analysis.

The model has two state variables, the first is the step number

(time). The second state variable (stock) is the inventory

level. Cells with yellow color and red outlines hold formulas

linking the cell contents to entries on the data worksheet.

In particular the maximum for state variables are linked to

the corresponding values on the data form. The cost coefficient

for stock (G21) has a formula that evaluates as the unit holding

cost when the stock level is positive and the negative of the

unit backorder cost when the stock level is negative.

The action variable has two dimensions. The first indicates

whether a replenishment order is placed, and the second is the

amount of the replenishment (lot size). The logical condition

in K17 returns FALSE when the replication variable is 0 and

the lot size is greater than 0. |

| |

State subsets are included in the model to

identify the terminal states. All states with time equal

to 41 exit to the final state.

A decision is the combination of a state and

an action. The decision subsets limit feasible combinations.

The bounds of Decision 1, allow orders when the stock

is at or below the reorder point. The order size is limited

between the minimum and maximum lot size. The current state,

(1,0), and action,

(1,12), satisfy these requirements.

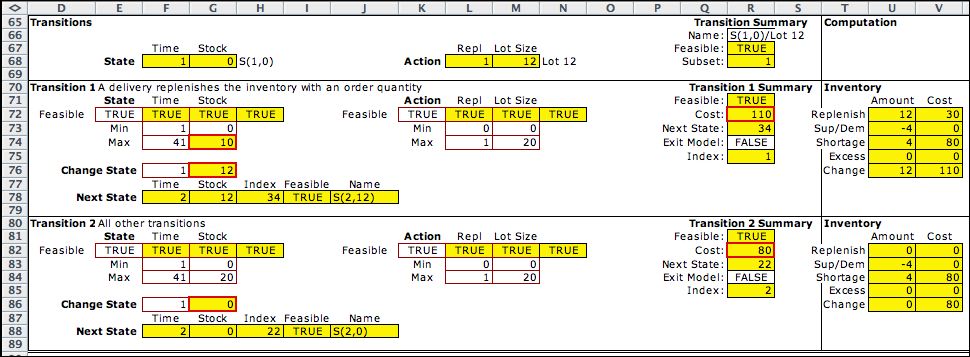

The transitions for the DDP compute the next

state given the current state and action. Computations unique

to the inventory problem are performed in columns T through

V. The numbers computed there give the Change State vector

and the Cost for each decision.

|

Enumeration |

| |

Clicking the List Elements button

at the top of the model worksheet causes the program to sequence

through all feasible states. The resultant list has 862 entries.

The last state is the Final state.

...

The action list has the Hold action that indicates

that the replenishment quantity is 0. The other actions prescribe

replenishment amounts between 10 and 20.

|

Decisions |

| |

For the DDP problem, feasible

decisions and transitions are shown in the Decision List.

A decision is described by a state and an action. The first

25 decisions are shown below.

...

There are 5702 decisions for this model. The decisions for

step 41 all go to the Final state. The final state

has a null transition. |

Call Solver |

| |

The DDP model uses the DP

Solver to find solutions. The Transition structure available

for the DDP is the Transition List. A different name

can be specified other than the one provided.

Part of the DP Solver worksheet is shown

below before optimization.

|

|

| |

Clicking the Solve button

presents the iteration dialog. The Acyclic option

is best for this problem since the state transitions always

go to a state with a greater index. The single

exception is the final state that has a self loop. The Acyclic

option solves the problem in a single pass through the states

from bottom to top.

At the completion of the computation, the solver model has the

solution shown in columns K through L. The optimum action

for each of the 862 states has been determined. The results comprise

the optimum policy.

|

|

| |

For a deterministic problem, the

solution can be traced from an initial state to the final state.

To find the optimum, click the Recover Optimum button.

Choose the intial state index. For the example we choose state

1. S(1,0). Clicking OK constructs the list of states on the

optimum path from the initial state. The list is placed just

below the state

list. Starting from state 1, the optimum

sequence of states with their corresponding actions is shown

below. |

| |

|

| |

The chart of the inventory levels

is below.

Because the lead time is 1 step, the first step

has lost sales of 4. After that the replenishment quantities

always satisfy all demand. Every order replenishes the sum

of some number of steps into the future. For example the 12

units delivered at the end of step 1 satisfies the requirements

of periods 2 through 6. |

Summary |

| |

The complexity of the deterministic problem

depends on the numbers of states and decisions.

For this model, the number of states is equal to the number

of steps in the time horizon multiplied by the number of integers

in the range between minimum and maximum inventories. If either

of these numbers is large, the number of states is also very

large. The number of decisions is always greater

than the number of states.

|

| |

|