| |

A problem that benefits from the side model construction

is the multiperiod problem. Here the problem is to plan the

operations of some system over several periods during a time-planning

horizon. Some decisions are made at the beginning of the horizon,

while others are made in each period. Certain variables link

the decisions from one period to the next.

We illustrate this case with the aggregate scheduling problem

described in the modeling

section. A company wants a high level, aggregate production

plan for the next 6 months. Projected orders for the company's

product are listed in the table. Over the 6-month period, units

may be produced in one month and stored in inventory to meet

some later month's demand. Because of seasonal factors, the

demand for the product and the cost of production is not constant,

as shown in the table.

Aggregate planning data |

| |

Demand |

Production |

|

Month |

(units) |

cost ($/unit) |

|

1 |

1300 |

100 |

|

2 |

1400 |

105 |

|

3 |

1000 |

110 |

|

4 |

800 |

115 |

|

5 |

1700 |

110 |

|

6 |

1900 |

110 |

The cost of holding an item in inventory for 1 month is $4/unit-mo.

Items produced and sold in the same month are not put in inventory.

The maximum number of units that can be held in inventory is

250. The inventory level at the beginning of the planning horizon

is 200 units; the inventory level at the end of the planning

horizon is to be 100. The problem is to determine the optimal

amount to produce in each month so that demand is met while

minimizing the total cost of production and inventory. Shortages

are not permitted. The general model is below.

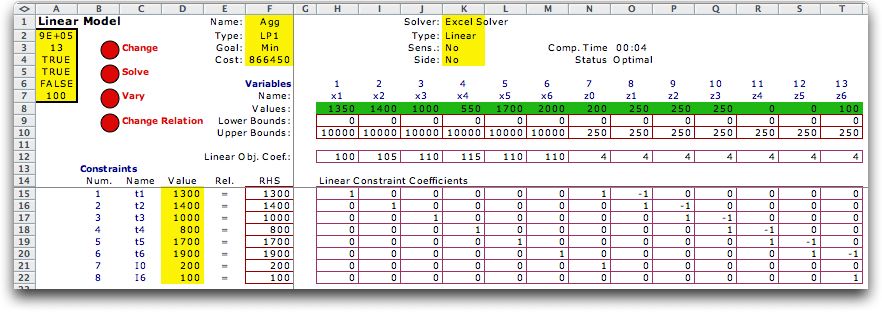

We construct the model with the Math Programming add-in and

solve it with the Excel solver to obtain the solution below. |

|

Using the Side Model |

| |

In the formulation above one notes

that the constraint matrix is sparse, that is, it contains

many 0's. This is usually true in a multiperiod model because

most of the variables appear in the constraints associated

with only a single period. For this simple example there is

only one constraint per period. Each production variable is

present in only one constraint while each inventory variable

appears in two. We will construct a more compact model using

the side model feature. For this purpose we identify

the inventory variables as the linking variables in the master

problem and the production variables as the side variables

in the subproblems. First we construct the master problem shown

below.

Only the inventory variables are included with the two constraints

describing the beginning and ending inventory. The solution

to the model has no meaning since important information

regarding demand and production cost is not included.

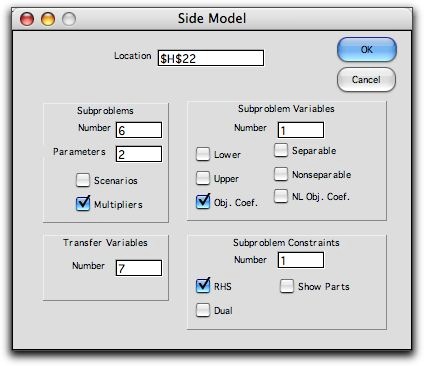

To create the subproblems. choose Side Model under

the Math Programming add-in entries in the ORMM menu

item. The dialog below contains the parameters of the side

model.

The cell field indicates the location

on the worksheet for the side model. Replications is

the number of rows, or individual subproblems to construct. Parameters indicates

the number of columns to include with model related parameters.

Transfer is the number of linking variables. Variables is

the number of side variables in each of the subproblem rows.

The Obj. box indicates that a column is to provided

for objective coefficients of the side variables. Constraints indicates

the number of constraints for each row of the side model. The RHS box

indicates that a row is to be included for the Right-hand-side values. Clicking

OK results in the side model below. The formulas shown in row

19 link the data in the parameter columns to the objective

and RHS columns. |

|

| |

The T and W matrices are composed

entirely of 1's. The D rows determine the contribution of the

master transfer variables to the constraints.The constraints

described by the side form are:

z0 - z1 + x1 = 1300

z1 - z2 + x2 = 1400

z2 - z3 + x3 = 1000

z3 - z4 + x4 = 800

z4 - z5 + x5 = 1700

z5 - z6 + x6 = 1900

The model form includes a Change button that allows

columns of the side model to be added or deleted. Addition

of columns is possible only if the associated region currently

has at least two columns of that type. In the example, the

numbers of parameters and transfer variables can be increased,

but the number of side variables and side constraints cannot.

When we click the Solve button at the top of the

page. The solution to the combination of the main model and

the side model is obtained. The solution is the same as when

all the variable and constraints were included in the same

model. |

|

Adding Fixed Charges |

| |

For such a simple problem, there

does not seem to be a very large savings when using the side

model, rather than including the entire problem in the master

problem. More savings are apparent when the side model grows

in size. For an example we change the problem to add a fixed

charge whenever nonzero production occurs. The fixed charge

might represent the setup cost for producing a product.

The master problem shown below is the same as

the original except we have increased the maximum inventory

to allow a more interesting solution. The figure shows the

optimum solution |

|

| |

The side model is shown below with

the optimum solution to the subproblems. We have included the

parameters directly as the RHS of the period constraints and

the objective coefficients. The setup costs result in fewer production

runs over the time horizon. |

|

| |

For this example, the addition of

setup costs increased the number of variables and constraints

by 6. If the side model was not used the constraint matrix would

have increased from 8*13 = 104 cells to 14*19 = 266 cells plus

additional cells in the variable and constraint limits. The change

more than doubles the number of cells required. Using the side

model, the change required only 49 additional cells for the side

model. The value of the side model increases as the complexity

of the individual subproblems. increases. The structure of the

subproblems is easy to check and the parameters are easy to apply.

The side model formulation does not change the model. It simply

makes it easier to represent the model on the worksheet. |

| |

|