|

|

|

Combinatorics |

|

-Routing

Problem - Multiple Vehicles |

|

The Routing/Multiple command creates

a model that is the same as the Routing/Single command

except that more than one vehicle (called trucks in

the following) can serve the sites of the problem. The more general

class of problems is called the Vehicle Routing Problem (VRP).

This model can address a variety of practical situations. |

|

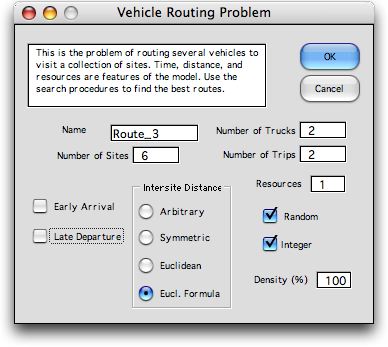

The dialog has

the same features as the single vehicle case except three

new fields are provided. The Number of Trucks field

indicates the number of trucks that can be sent on independent

routes at the same time. The Number of Trips field

indicates the number of separate trips these trucks can

take. A number greater than the number of trucks indicates

that a truck can take more than one trip in a day, but

must visit the depot between each trip. A Resource is

some feature of a truck that is used up when the truck

visits a site. The program allows more than one resource.

The minimum number is 1.

|

|

| |

Features of the problem are illustrated

by the example. It is the same as used on for the single vehicle

problem except here there are two trucks serving the six

sites. The two trucks are identified by the headings Depot

1 and Depot 2 in columns D and E of the model. The data in

these columns refers to the two trucks. Column L has a third

depot entry, Depot 3. This column represents the end of the

route.

The distance matrix starts in row 15. A single depot is assumed

and the distances related to all depot columns (D, E and L)

are the same. We color these entries gray to show that they

are determined by formulas and should not be changed directly.

The location of the depot in the x, y columns (columns

M and N) controls all the distances related to the depot columns.

The initial decisions in row 9 define a route that visits

each site in numerical order. Since the first two indices represent

separate trucks, the solution does not have interest. It will

be changed when we search for the optimum. |

| |

|

| |

One new data item appears below

the distance table and that is row 33 holding the resource

values. The resource is something that is provided by the truck

but is used up by the sites on its route. Resources could represent

weight, deliveries, packages or some other measure of capacity.

Here we use the site count as capacity and indicate that each

truck can visit half of the sites. Each truck has a capacity

of 3 and each site reduces this capacity by 1 (the resource

contribution of a site is -1). The number labeled P1, the value

1000 in cell M33, is the penalty for violating the resource

constraint.

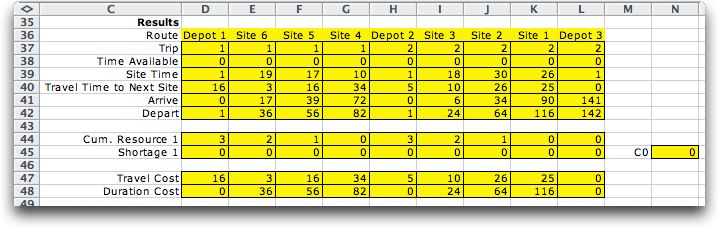

Computations related to the resource are in rows 44 and 45.

Row 44 computes the cumulative resource use of the route. Whenever

a depot (or truck) is encountered on the route, the resource

of the truck is placed in the associated cell. For the example,

truck 1 in column D contributes the resource value of 3 in

D44. Since the route immediately passes through the depot,

truck 2 contributes its resource value of 3 in E44. The resources

contributed by trucks do not add as it is assumed that every

time the route passes through the depot a new trip begins.

As the route proceeds through the sites, the cumulative value

of the resource declines until it becomes negative. Columns

I though K show negative values in row 44. A negative value

indicates a shortage of the resource. Shortages are reported

in row 45. The total cost of shortage is the total shortage

multiplied by the shortage penalty. It is computed in cell

N45. All these quantities are automatically computed with Excel

formulas indicated by the yellow color of the cells. |

| |

|

| |

The travel, duration and shortage

costs are added in cell F5 at the top of the worksheet. This

is quantity is the objective function that is to be minimized. |

Optimization |

| |

We choose a solution method by clicking the

Search button on the worksheet. The button calls a

dialog from the Optimize add-in for selecting the

solution method. The dialog shows the Random search

method chosen. This means that 10 random solutions will be

generated and the best of the ten solutions will be reported.

We did not choose the Exhaustive option in this case

because it requires over 5000 solution evaluations.

The results of the random search are shown below. The route

follows (Depot 1, 2, 4, 5, Depot 2, 3, 6, 1, Depot 3). This

solution implies that truck 1 serves sites 2, 4 and 5, and

truck 2 serves sites 3, 6 and 1. Notice that the arrival and

departure times indicate that the two trucks operate at the

same time, both starting at time 0. The solution has no shortage

since each truck serves three sites. The total cost is 555. |

| |

|

| |

The map showing the route is below. The route

has two parts the first truck is shown in red and the

second in green. |

|

| |

To improve the solution, we again click the Search button,

but then choose to improve the current solution.

|

| |

The resultant solution is shown below. The

route follows (Depot 1, 6, 5, 4, Depot 2, 3, 2, 1, Depot 3).

The total cost of this solution is 513.

The map for this solution is below. |

|

| |

Additional investigation

may find better solutions. |

|

| |

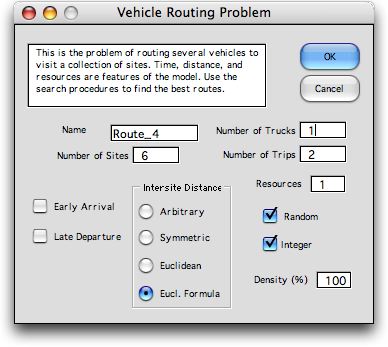

With more trips than trucks, a truck

may cover more than one trip. The trips occur sequentially in

time. To illustrate, consider a problem with a single truck,

but with two trips.

The model shows one depot column (column

D) at the left of the form, representing a single truck. Two

depot columns are at the right (columns K and L). Column K

describes the second trip of the truck, while column L is the

destination at the end of the route. The resource row (row

33) assigns 3 to each truck and -1 to each site. The solution

shown in the figure is the result of the search process described

below. |

|

| |

We search for the optimum by first

generating 10 random solutions and then improving the best

of these. The results are shown below. The

route follows (Depot 1, 3, 6, 5, Depot 2, 2, 1, 4, Depot 3).

The total cost of this solution is 800. The interesting part

of these results is the row labeled Arrive. Although

the solution includes two trips, they are both accomplished

by a single truck. After leaving site 5 at time 73. The truck

arrives at the depot at time 92. One minute later it leaves

for the second trip. The truck returns to the depot after the

entire route is complete at time 249. |

| |

|

| |

The map describing the solution

is below. Notice the first trip indicated by the red lines

is much shorter than the second trip. This is due in part to

the duration penalty. The penalty causes sites with high site

time and located far from the depot to be serviced as late

as possible.

|

|

|

| |

The previous examples used multiple trips because

of limited resources. Time windows also create the necessity

for extra trucks and multiple trips. To illustrate, I created

a problem with 20 sites, two trucks and four trips. Each trip

is given a resource of 5, so that a feasible solution

divides the sites evenly between them. Each site was given

a latest departure time of 240 minutes. Although

the problem is too large to present here, it is included in

the demonstration file for this section. A solution was found

by choosing the best of 100 randomly generated solutions. The

2-change improvement method was applied to that solution. A

map of the solution is below. |

|

| |

The red and green trips are for the first truck

and the black and blue are for the second. The solution shown

is not feasible because the first trip has six sites. A feasible

solution obviously exists, but the search did not discover

one. The solution also has some late departures. |

| |

|

|