| |

Similar

to the sequential method, the CRAFT method also investigates

departments for switching. Candidates for switching are pairs

of departments that have the same area or pairs of departments

that are adjacent in the layout. For example, consider the feasible

switches that involve department 6 in the layout above. Departments

2 and 8 have the same area, so the pairs (2, 6) and (6, 8) are

feasible. Departments that are adjacent to 6 are departments

3, 5, 7, 9 and 10, so the pairs involving these departments

and department 6 are feasible.

To evaluate the effect of switching the

two departments, the CRAFT method assumes that the centroids

of the two departments are switched and computes the resultant

cost savings. When the two departments are the same size, this

evaluation is accurate. When the departments have different

sizes, the centroids of the departments do not exactly switch

locations. In this case the evaluation may be not be accurate

and a switch that looks promising may actually increase the

cost of the layout. The CRAFT method implemented by this add-in

terminates if this occurs.

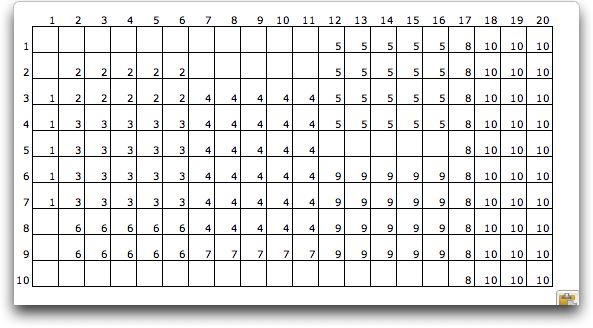

For the example, the best feasible pair

is 9 and 10. Since the two departments are different sizes,

there are many alternatives for arranging the cells of the smaller

sized department 9 into the larger area formerly holding department

10. The program has an algorithm for choosing the arrangement

that results in the layout below. Although one might question

the logic of this arrangement, it is difficult to program an

algorithm that always makes the most reasonable assignment.

The user can adjust the assignment of cells by changing cell

indices, but this is a manual operation. |

| |

The next iteration

interchanges departments 2 and 5. Note that this change causes

department 5 to overlap two widths of the formerly sequential

layout. Although we started with a sequential layout, the CRAFT

method does not consider department widths in its algorithms.

We have erased the lines representing aisles, because no aisles are implied by the CRAFT layout. |

| |

The

program next determines that if the centroids of departments

7 and 8 are switched, the cost of the layout will be reduced.

When the switch is actually made, the cost increases. The add-in

recovers the solution before the switch and terminates. The

summary of the CRAFT process is shown below. |

| |

The

CRAFT method is not restricted to initial layouts obtained

by the sequential method. By choosing Blank on

the dialog, a blank layout is presented.

An initial layout is constructed by placing numbers or colors

on the layout. One possible initial layout is below.

The blank spaces might represent the

actual building shape or unusable portions of the facility. Pressing

the Evaluate button,

colors the cells and evaluates the layout. |