| |

The

sequential layout is defined by the department width and the

sequence used to layout the departments along the aisles of

the facility. The optimum sequence method of solution

starts with an arbitrary initial sequential solution and tries

to improve the layout by switching two departments in the sequence.

At each step, the method computes the cost changes for all possible

switches of two departments and chooses the most effective pair.

The two departments are switched in the sequence and the method

repeats. The process stops when no switch results in a reduced

cost. To illustrate we start with the departments sequenced

in order of department index as below. |

| |

|

| |

Clicking

the Solve button presents the dialog below. The top

button stops at each iteration to show the new layout. The second

button stops when there is no further improvement. |

| |

|

| |

Starting

from the initial sequence, the program finds the best switch

and presents its conclusion below. |

| |

|

| |

Clicking Yes

causes the change in layout. Notice that departments 9 and 10

are switched in sequence and in location. |

| |

|

| |

The

next best switch is departments 1 and 3. Notice that the change

in sequence affects the relative locations of the departments

switched. When the departments are of different size, the locations

of all departments between are also adjusted. |

| |

|

| |

We

restarted the process with the initial sequence and chose the

Do Not Stop option. The process stopped with no further

improvement after one additional switch of departments 6 and

7. The result is shown below. |

| |

|

| |

To

the right of the layout appears a summary of the switches made

during the process. |

| |

|

| |

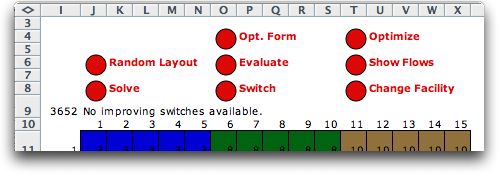

Above

the layout there are several additional buttons. The Random

Layout button generates a random sequence of departments

and places them on the layout. Since the switch heuristic does

not guarantee optimality, it is useful to start at several different

solutions and select the best.

The Evaluate button evaluates

the current sequence placed in column G of the worksheet.

The user can manually change the sequence. The Switch button

allows the user to force the program to switch two departments.

The Change Facility button allows the user to change

features of the facility, such as length, width or department

width, or change the solution options. The Show Flows

button draws lines between centroids to show the flows. We

discuss the Opt. Form and Optimize buttons

later. |

| |

For

the example we generated a random sequence using the Random

Layout button and performed the switch procedure until no

improvement was possible. The resulting layout is shown below

with the summary results. Note that this layout is much different

that the one previously discovered. Its cost is slightly larger

than before. |

| |

|

| |

|

| |

We

initiated the layout with a department width of 4 with the resultant

sequential layout as below. |

| |

|

| |

After

a sequence of switches we obtain the final layout shown with

its summary below. |

| |

|

| |

|

| |

Clicking

the Show Flows button shows the flow lines between

departmental centroids. The thickness of a line shows the relative

magnitude of the flow-cost between two of the departments. Four

different thickness are used with a thin line indicating a relative

small flow-cost between two departments and a thick line indicating

a large flow-cost. |

| |

|

| |

The sequential layout

can be easily automatically generated. The sequential layout

method quickly finds good layouts for alternative facility designs.

The Traditional Craft method is an alternative. It

is described on the next page.

|

| |

|