|

|

|

Facility

Layout |

|

-Defining

the Facility |

| |

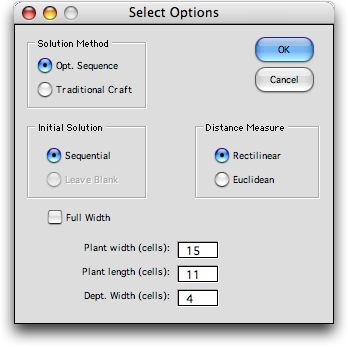

The

button on the Layout Data worksheet presents the dialog

box shown below with which the various solution options

are selected. The distance between two departments is the

distance between their respective centroids. When

material movement is parallel to the length and width boundaries

of the plant, it is reasonable to use the rectilinear measure.

When the movement is via straight lines between the two

centroids, the Euclidean measure is appropriate. Two

solution options are available, the Optimum Sequence method

and the Traditional Craft. We first discuss the Optimum

Sequence method. The length and width of the plant and the

aisle width are set in the fields at the bottom. |

| |

|

| |

The

facility layout worksheet has various parameters and options

listed at the top of the page as illustrated below. The cells

on this worksheet that are colored yellow hold either formulas

or data controlled by the program, so they should not be manually

changed. The worksheet name should not be changed.

At the top of the page in column B we

see the name, number of departments, length and width of the

facility, total area and the cost for the current layout (shown

in the next figure). We hope to find a layout that minimizes

the cost in cell B8. Column E holds parameters that are described

subsequently.

Starting in row 11, a row is provided

for each department. Column A holds the department name,

column B holds its color, column C holds the area defined

on the Layout Data worksheet, column D holds the area defined

for the department on the current layout. Columns E and

F hold the computed centroids of the department. For this

example, we are using an Aisle

layout. Column G shows the sequence number of the department. The

ranges shown in green hold numbers computed by the program. |

|

|

|

When

the Sequential button is selected for the initial solution,

a layout is automatically generated with the departments listed

in numerical order in column G. This is the default initial

sequence, but the numbers in this column can be changed to accommodate

a user-supplied initial sequence. This is important if some

departments are given a fixed index in the sequence.

The Leave Blank option is available

only with traditional craft. Here the layout is left blank initially

and the user must manually define the department locations in

the layout. The layout is immediately to the right of this data

on the worksheet.

The initial layout for the example was

generated with the default sequence using an Aisle layout and

is shown below. |

| |

|

| |

The layout starts

in cell J11. The number of colored cells to the right of J11

is the width of the facility and the number of colored cells

below J11 is its length. The locations of the departments are

specified by department indices or colors. The initial layout

can be entered manually or automatically. It is most convenient

to use an automatic Aisle layout. The aisles are indicated

by the white lines running through the centers of the departments.

This layout form is often associated with the ALDEP layout construction

procedure.

The aisle layout is determined by the

department width, which for the example is equal to 5, and the

sequence of departments. For the example we have chosen the

sequence as the department indices. The first department in

the sequence starts in cell J11 and is assigned cells to the

right until the department area is completely defined or the

department width is reached. For the example, department 1 requires

all five cells. The second department is placed below the first,

using as many rows as necessary to enter the entire area. We

continue to add departments until the entire length of the facility

is used. Then the departments are placed at the bottom of aisle

2. In the example, department 4 uses both aisles 1 and 2. The

layout continues up aisle 2 until the top is reached for department

8. The the layout proceeds down aisle 3 until all departments

are placed. For the example, five cells remain unused. The white

lines on the layout show the serpentine nature of this layout

procedure.

To illustrate the effect of a different

department width we click the Change button. The dialog

below is presented. Any of the options may be changed

by clicking a button or changing the fields defining the width

and length of the plant and the depth of an aisle. In this

case we change the depth to 4.

Because the department areas are not

multiples of 4, the layout becomes more irregular. This affects

that accuracy of distance measurements since department centroids

are no longer in the center of rectangular departments. |

| |

|

| |

An

alternative layout that more nearly maintains rectangular departments

is obtained when the Full Width box is checked. The

result for the example is shown below. For this option, departments

are increased in area so that they fill an integral number of

rows of the layout. Note that the area of department 1 has increased

from 5 to 8. Of course, when department areas are increased,

it may be necessary to increase the size of the facility. This

is the case for the example where it is necessary to increase

the length of the facility to 12 so that the larger departments

can be accommodated. |

| |

|

| |

The next step is to

search for the optimum layout. We consider first the Optimum

Sequence method and then the Traditional Craft method

on the following pages. |

| |

|

|