|

|

|

Process

Flow Models |

|

- Defects

|

|

A principal

cause of waste in a production process is the introduction of

defects. The possibility of defects leads to the necessity of

inspection. The results of inspection may be the discard of the

product as scrap or routing to a rework facility. The discovery

and repair or discard of defective items results in additional

variability in the production process. There is also the possibility

that a product with an undiscovered defect is shipped to the

customer. When the customer ultimately discovers the defect there

is the cost of warrantee repair and the loss of customer good

will. All these results are waste. This section describes the

mathematical models used by the add-in to model the creation,

combination and discard of defective items. |

| |

|

The defect feature

of the model is added by checking the Defect checkbox.

The figure shows that the Proportion box is also

checked as the defect model requires the proportion feature. |

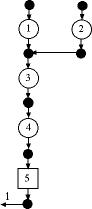

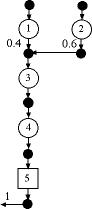

Figure 1

|

A number of kinds of defects might be introduced by

a production process. A fatal defect when present in

a product will cause the product to fail in some way

to satisfy its specifications. In this section, we restrict

attention to fatal defects.

For analysis purposes, we define the probability that

operation i introduces a defect into a unit of

product as  .

To compute the defect probability associated with two or

more operations, we assume that the events producing defects

are statistically independent. .

To compute the defect probability associated with two or

more operations, we assume that the events producing defects

are statistically independent.

Fatal defects are discovered only through inspection.

If discovered, a defective item will be discarded as scrap.

If not discovered, a product with a defect will pass to

other operations to receive subsequent processing. If the

finished product leaves the process with a defect, it is

ultimately discovered by the final inspector, the customer.

Although an item may be made defective by more than one

operation, one fatal defect is sufficient to cause the

failure of the product.

No defects are discovered at non-inspection operations,

however, there may be other sources of scrap at these operations.

For example, a non-inspection operation may have a scrap

factor that represents material removed and discarded.

We also may identify a second kind of fatal defect that

can be immediately observed by the operator and discarded.

For instance the operation may break the item causing immediate

discard. Both these mechanisms will be incorporated into

the scrap proportion for the non-inspection operation.

We assume that discards of this fashion do not affect the

defect probabilities or the way in which the probabilities

combine to determine the removal rate at inspection operations.

To illustrate, consider the process with four serial operations

followed by an inspection station as in Fig. 1. Assume

that each operation introduces fatal defects in 10% of

the items passing through it. The inspection station is

perfect in that it finds and removes all defective items.

The inspection operation is shown as a rectangle in the

figure. The process worksheet with this data is shown below

along with the computed results. Note that an inspection

station is identified by the word "Inspect"

in the Type column. Only the first two letters are used,

so alternatives such as "In" or "Inspect

1"

also represent inspections.

The Defects Out column shows the proportion of

the items that are defective at each operation, and the Flow

Removed column shows the proportion that are removed

from the flow. Note that the defects accumulate in the

flow as it passes through the process. When items finally

reach the inspection station, the defects are discovered

and approximately 35% of the flow is discarded. Since this

example assumes perfect inspection, the defect rate at

the output of the inspection is zero. The effect of the

discard of so many defects is to increase the unit flow

to over 1.5 for all the operations. For each unit that

passes out of the process, 1.5 units must be processed.

The throughput time and WIP is increased proportionally. |

|

|

| |

The

following describes the columns that are important for the

discussion of defects. |

| |

Data Items and Result Items for the Example

Column |

Title |

Explanation |

G |

Defect Rate |

This is the percentage of products

passing through a processing operation that receive defects.

We assume a single defect warrants discard of an item,

however, the defects are only discovered by an inspection.

Defects do not change the flow except for an inspection

operation. For an inspection operation, the defect rate

is the proportion of defects not discovered and

discarded.

|

H |

Proportion |

For a pull system, this is

the proportion of the flow entering the next node that

comes from the operation specified by this data line. For

a push system, this parameter is the proportion

of the flow leaving the operation that goes to the next

operation. The proportion column is necessary when defects

are present.

|

M |

Defects

Out |

For a processing operation ("Op"),

this is the proportion of the items leaving an operation

that have defects. We assume that the defect producing

mechanisms in different operations are independent. The

function in this cell combines the probabilities of defective

parts entering the operation with the defect probability

for the operation to obtain the probability that an item

leaving the operation is defective.

For an inspection operation ("In"), the probability

of a defective part leaving is zero if the inspection

is perfect, that is inspections find and remove all defective

items. If the inspection is not perfect, the function

computes the probability that a defective item leaves

the inspection.

|

N |

Flow

Removed |

For a processing operation, this

cell then contains the adjusted scrap rate for the operation.

When the operation is an inspection, defective items are

removed as waste. The proportion discarded is shown in

this column.

|

O |

Ratio |

This is the ratio between output

flow and input flow for an operation.

|

|

Pull

serial process |

| |

Fig. 1 is an example of a pull serial process.

The flow is not affected by defects until it reaches an inspection.

There, some or all the defective items are removed. To compute

the amount removed, we must first compute the probability

that an item entering an inspection is defective. When inspection

is perfect, this probability becomes the removal rate at the

inspection operation.

Consider the example in Fig. 1. Assuming the

material entering operation 1 has no defects, the probability

that a defect is produced is  .

Since they are not removed, defective units are still processed

in operation 2 along with the non-defective ones. Assuming

independence, we can compute the following probabilities about

the output of operation 2. .

Since they are not removed, defective units are still processed

in operation 2 along with the non-defective ones. Assuming

independence, we can compute the following probabilities about

the output of operation 2.

These probabilities are computed in the Defects

Out column, where we see 0.1 as the probability of a

defect at the output of operation 1 and 0.19 at the output

of operation 2. There is a 0.01 probability that an item has

two defects after passing through the first two operations.

The remaining entries in the Defects Out

column are computed similarly using a recursive relation

The Flow Removed column (J) shows the

proportion of the flow that is discarded as scrap. For non-inspection

operations, no flow is removed. For a perfect inspection,

the scrap rate of the inspection operation is set equal to

the defect probability at its input and the proportion of

defects out becomes 0. When the inspection is not perfect,

we use  as the probability that the inspection does not detect a defect.

as the probability that the inspection does not detect a defect.

|

Push

serial process |

| |

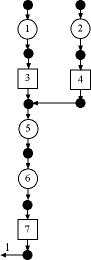

Figure 2

|

The effect of defects in a push serial system are

the same as for the pull serial system as illustrated

in Fig. 2 and in the worksheet for this process. The

defect rates are the same as for the pull example,

but the flows are different because of the different

drive mechanism for the push process. For every unit

entering node 1 approximately 0.66 units leave node

5.

|

|

|

Pull

non-serial process |

| |

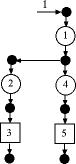

Figure 3

|

We observe the effects of defects in a non-serial

process in Fig. 3. When two or more branches come together,

as the outputs of 1 and 2, the probabilities of defects

combine.

Thus we have at the output of operation

3, the probability of defect:

1 - (1 - 0.1)(1 - 0.1)(1 - 0.1) = 0.271

The results for the example in Fig. 3

are almost the same as the results for the example

of Fig. 1. The only difference is for operation 2 that

has a defect probability of 0.1 rather than 0.19. This

does not affect on the unit flows, because the same

number of defects are produced and are not eliminated

until the inspection station is reached at the end

of the process.

|

|

|

| |

Figure 4

|

The process of Fig. 4 is the same Fig. 3 except we

add inspection stations before the assembly operation

at 5. The operations have been renumbered to meet the

restrictions of a tree structure.

The Excel worksheet for the example shows that the

extra inspection stations reduce the unit flows in

all the operations. The throughput time and WIP are

increased because of the extra inspection time.

For a process with defects, the problem of finding

the optimum location and number of inspection stations

is relevant. With additional cost information, this

add-in can guide the search for an optimum.

|

|

|

Push/tree

structures |

| |

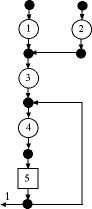

Figure 5

|

The process of Fig. 5 is a push tree. Defects are

produced in operations 1, 2 and 4, and removed at the

inspections at 3 and 5.

The analysis of a push tree is easier

than for a pull tree, since each operation in a push

tree has at most one predecessor. To illustrate, consider

operation 1 in the figure. Assuming the material entering

operation 1 has no defects, the probability that a

defect is produced is  .

Although defective units may be produced in operation

1, they are still processed in operations 2 and 4.

Assuming independence, we can compute the following

probabilities about the output of operation 2. .

Although defective units may be produced in operation

1, they are still processed in operations 2 and 4.

Assuming independence, we can compute the following

probabilities about the output of operation 2.

These probabilities are computed in the Defects

Out column. We see 0.1 as the probability of

a defect at the output of operation 1 and 0.19 at

the output of operation 2. There is a 0.01 probability

that an item has two defects after passing through

the first two operations.

The same computations can be made for

operation 4 which also receives its input from operation

1. Since all have the same defect probabilities, we

find the probability of defect at the output of 4 to

be 0.19.

The remaining entries in the Defects

Out column are computed similarly using the

recursive relation

The Flow Removed column (J)

shows the proportion of the flow that is discarded

due to defects. For non-inspection operations, no flow

is removed. For a perfect inspection, the removal rate

at the inspection operation is set equal to the defect

probability at its input and the proportion of defects

out becomes 0. When the inspection is not perfect we

use  as

the probability that the inspection does not detect

a defect. as

the probability that the inspection does not detect

a defect.

|

|

|

Network

Structures |

| |

Figure 6

|

The formulas for defect probabilities are applied

recursively, starting at the operations with the lowest

indices and passing to operations with higher indices.

The indexing for the operations of a tree assures that

this recursive approach is successful. For the more

general network structures, the recursive process is

not valid.

The add-in does not disable the defect option for

network structures, but it should be used with caution.

An example is in Fig. 6. This network structure is

the same as Fig. 3, but part of the output of inspection

station 5 is routed back to operation 3 for additional

processing. We assume that 80% of the input to operation

4 comes from operation 3, while 20% comes from operation

5.

Not considering the branch from 5 to the input of

4, the structure is a tree. We model the defects using

only that tree. In fact, this is valid for this example,

because the items routed from operation 5 do not contain

defects. The Excel model is below. The Next and Proportion columns

describe the tree structure and the Transfer In matrix

defines the network structure. It is important that

the two models are consistent.

|

|

|

Proportions |

| |

Figure 7

|

Most of the examples to this point used branch proportions

of 1. Here we consider situations in which proportions

may be other than 1. For pull/tree structures it is

necessary to adjust the defect formulas. Consider the

situation of Fig. 7. The numbers on the branches entering

operation 3 imply that 40% of the items passing through

operation 3 receive items from operation 1 and 60%

receive inputs from operation 2. To compute the defect

probability for an operation receiving several inputs

we use the following general expression.

For the example, we have at the output

of operation 3, the probability of defect:

1 - (1 - 0.1)[1 - (0.4)(0.1)][1 - (0.6)(0.1)]

= 0.1878

This result is rounded to 18.8% on the

worksheet below.

For the push tree the defect probabilities

are not affected by branch proportions.

|

|

|

Grouping

Factors |

| |

Figure 8

|

In the example of Fig. 8, four items from operation

1 are grouped to form a single item passing out of

operation 2. For example, four sheets of plywood might

be glued at operation 2 and four individual sheets

becomes one assembled item for subsequent processing.

At operation 4, the process divides the item in some

manner, so that one item becomes four in subsequent

processing. Continuing with the plywood example, perhaps

operation 4 cuts the assembled plywood sheets into

four individual smaller parts.

Grouping factors are useful in a variety of contexts

and defect probabilities must be adjusted to account

for them.

The expression assumes that the items

are grouped prior to the operation. Any defects produced

at the operation are not raised to the power.

In the example, we introduce 10% defects

in operation 1 with no further defects in the subsequent

operations. At operation 2 we group four of the items

into one. The defect probabilities for the operations

are computed recursively, starting from operation 1.

|

|

|

User

Defined Functions |

|

|

The defect proportions are computed using User Defined

functions provided by the add-in. There are two different

functions used in pull and push trees respectively. The function

used for pull trees is:

= pull_defect(op_type, index, next_range,

prop_range, defect_range, d, g)

The arguments labeled range refer to

the named ranges on the Excel process definition. Algebraically

the function computed is:

For push trees the appropriate function is:

= push_defect(op_type, prev, index_range,

prop_range, defect_range, d, g)

The arguments labeled range refer to

the named ranges on the Excel process definition. Algebraically

the function computed is:

The functions are placed in the Defects

Out column. The arguments on the worksheet are references

to the cells holding the appropriate parameters.

The process definition also uses functions to compute the

amount removed at the operation. These functions combine the

effects of scrap removed at an operation and items removed

due to defects. Different functions are required for pull

and push trees.

= pull_remove(op_type, Index, next_range,

prop_range, defect_range, Scrap, d, g)

= push_remove(op_type, prev, index_range,

prop_range, defect_range, Scrap, d, g)

The functions are placed in the Flow Removed

column of the process definition. The contents of the Flow

Removed column is used to compute the Ratio column.

|

| |

|

|