|

|

|

Process

Flow Models |

|

- Queues and Inventories

|

|

There are

features of processes that cannot be modeled by linear models.

This is particularly true of the effects of variability. Although

the process flow model is deterministic and does not explicitly

represent the variability often present, it is possible to include

estimates of the average time delays due to a variety of causes.

We do this by providing an Excel user function call time_f (time

function). Four models are currently built into time_f.

On this page we describe three models: one to model the delays

from queues, another to model the delays due to inventories and

the third to model delays due to changes in lot sizes. A fourth

model that computes lost time due to production lines is on the

next page. |

| |

|

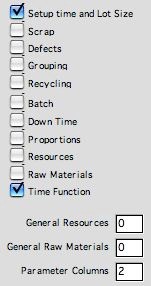

To include inventory

or queue models, check the Time Function box on

the Add Process dialog . It is unnecessary

to check the Setup time and Lot Size box, but

the lot size column is automatically included, whether

or not this box is checked. The lot size column is used

by the time function.

The time function requires two parameter columns. The

user might add other Excel function models in the process

definition. Any number of parameter columns can be included

to hold operation parameters for these models. The number

is specified in the field at the bottom of the dialog. |

|

To illustrate the use of the time

function feature, we use a serial pull process with

inventories and queues. The triangle for operation

1 represents the raw material inventory. The triangle

for operation 6 represents the finished goods inventory.

The d-shaped symbols for operations 2 and 4 are delays

for the queues waiting for machining operations 3 and

5.

Parameters for the operations are

on the Excel worksheet below. The worksheet is shown

in two parts for clarity. All operations use lot sizes

of 10. Only operations 3 and 5 have nonzero operation

times. Scrap and defects are not included, so all ratios

are 1 and all unit flows are 1.

Of interest to the time function

are the two parameter columns, P1 and P2 and the Time

Function column holding the time functions. |

|

| |

|

| |

Data Items and Result Items for the Example

Column |

Title |

Explanation |

B |

Type |

This column is used to identify the

type of the operation. It is particularly important for

the time functions. The time function uses the first three

characters of the type to identify the function to be evaluated, "que" for

queue, and "inv" for inventory, and "lot" for

lot size change. When the type includes the word "line",

the production line formula is

evaluated.

|

H |

Lot Size |

This is the number of units processed

in a lot.

|

I |

P1 |

This is the first parameter column.

The column title may be changed for clarity. For the queue

model, the column holds the average service rate for the

servers of system. For the inventory model, the

column holds the replenishment rate for the inventory system.

The default value, 999999, is meant to represent infinite

service rate or infinite replenishment rate.

|

J

|

P2 |

The second parameter column holds

the number of servers for the queuing model. It holds the

safety stock for the inventory model. Again the title of

the column may be changed. The default value is

1, represents a single server or a safety stock of 1. To

obtain a valid result for a queuing model, the number of

servers must be sufficient to handle the arrival rate.

|

K |

Time

Function |

This column holds the time_f function

provided by the add-in. For the row representing the

raw material inventory (row 7) the function is entered

as below:

=time_f(B7,F7,Q7,H7,I7,J7)

We explain the arguments of the function

for specific applications below.

|

Q |

Operation

Flow |

This is the total flow rate entering

the operation. It is the product of the unit flow and the

process flow V. Both queuing and inventory

models use the total flow rate to compute the operation

delay.

|

|

Queues |

| |

Consider row 8 of the example. It models the

queue for the machining operation described in row 9. The

important information from row 7 is

-

Column B: type = Queue

-

Column H: lot size = 10

-

Column I: service rate = 2/hour

-

Column J: number of servers = 2

-

Column Q: arrival rate = 2.5/hour

The argument in column F is the operation time.

It is not used for the functions on this page.

We have chosen the service rate to be the inverse

of the operation time in cell F9 (1/0.5 = 2). This is reasonable

since the queue is waiting for the service operation in row

9. The minimum number of servers in this case is 2. The result

of the computation, shown in column K, is the average time

each unit remains in the queue. The time does not include

the service time. The service time is added in row 9 that

represents the machining operation that follows the queue.

The queuing model assumes that units are processed

in lots. In general we call Q the lot size. For

the example, Q = 10 units. We assume that lots

arrive according to a Poisson process (the times between

lot arrivals

are exponentially distributed). For the example, the arrival

rate in lots is 2.5/10 or 0.25 per hour. An important result

for an Exponential distribution is that its coefficient of

variation (COV) is 1.

The service time for each unit is exponentially

distributed. The units in a lot are processed individually

and in sequence, so the time to process the lot is the sum

of Q exponentially distributed random variables.

The mean service rate for a lot is the service rate for an

individual unit divided by Q. For the example, this

is 2/10 = 0.2. The sum has a Gamma distribution. An important

result for a Gamma is that its coefficient of variation (COV)

is  . .

We use a non-markov queuing model to compute

the mean time in queue. The formulas used are the same as

used in the Queue add-in. The non-markov model uses

the arrival rate, service rate, number of servers, COV of

the arrival process, and COV of the service process. All parameters

are available from the row for Queue 1.

=time_f(type = "queue",unit arrival

rate,lot size,service rate,number of servers)

The data used for the queuing model is:

The result shown in cell K8 is the mean time

in Queue 1, 1.763 hours. This is actually the queue time

for a lot, but it is also the queue time for each unit. A

unit must wait as long as its lot waits. Holding items in

lots results in significantly increased queue times.

The queue represented in row 10 is similarly

analyzed by the time function to obtain a queue time of 1.1

hours.

|

Inventories |

| |

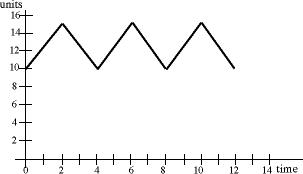

Inventories are another instance of variability in flow.

An example is the raw material inventory represented for the

example in row 7. Perhaps raw materials must be delivered

by truck and it is more efficient to deliver a quantity (lot)

of raw materials than a single unit. Then the pattern of inventory

could be approximated as below.

Using the data for the example, raw materials

arrive in lots of 10 units. Since the flow rate through the

inventory is 2.5 per hour, the orders must arrive every 4

hours. We are assuming here a continuous withdrawal of items

from the inventory, but arrivals occur at discrete times.

The variability causes a delay as units remain in inventory.

The time function that computes this delay has the parameters:

=time_f(type = "inventory",usage

rate,lot size,replenishment rate,safety stock)

In cell K7 we see the function call:

=time_f(B7,Q7,H7,I7,J7)

For the example, the columns holding the parameters

are:

-

Column B: type = Inventory

-

Column H: lot size = 10

-

Column I: replenishment rate = 999999/hour

-

Column J: safety stock = 0

-

Column Q: usage rate = 2.5/hour

The formula for average delay with an infinite replenishment

rate is:

For the example, the average delay for the raw

material inventory is 2 hours.

Row 12 represents the finished goods inventory.

Since that inventory is supplied by Machine 2, we assume that

the inventory is replenished at a finite rate equal to the

inverse of the unit processing time of Machine 2, 5 per hour.

If we assume that product is withdrawn from the system at

a uniform rate of 2.5 per hour, the finished goods inventory

pattern is as below. The inventory variation is on top of

the safety stock. Of course the figure is an abstraction.

Obviously it would be unnecessary to have safety stock in

such a well behaved system. The safety stock is used to handle

the variability of the output demand which in reality is quite

unpredictable.

The time function computes the average time

an item remains in this inventory with the formula below.

In cell K12 we see the function call:

=time_f(B12,Q12,H12,I12,J12)

For the example, the columns holding the parameters

are:

-

Column B: type = Inventory

-

Column H: lot size = 10

-

Column I: replenishment rate = 5/hour

-

Column J: safety stock = 10

-

Column Q: usage rate = 2.5/hour

For the example, the average delay for the raw

material inventory is 5 hours. The safety stock contributes

4 hours, while the cycle inventory contributes 1 hour.

|

Lot Size

Change |

|

|

It is common in some manufacturing systems to have different

operations to use different lot sizes. For example, the

first operation might have a lot size of 1 and a second

operation may have a lot size of 10. Considered in isolation,

we can compute the unit times of the two operations and

use them to compute the throughput time for the system.

This neglects, however, an important interaction that

results in a delay for items passing through the system.

That interaction is the lot size change activity.

When the lot size changes from 1 to 10, there must be

a delay while items from the first operation are gathered

to create a lot of size 10. The WIP created is a function

depends only of the input and output lot sizes. The formulas

are given in the discussion for the Inventory add-in.

The WIP is 4.5 for this example. The time function computes

the appropriate time delay for the lot size change operation.

|

Other

functions |

| |

No doubt there are other features of the process model that

could be implemented as a time function. Other features could

be implemented by changing

the time_f user function. It is accessible through

the Visual Basic code that implements the add-in.

It should be noted that the functions shown in this example

are valid only if the queues and inventories only involve

a single process. If multiple processes share inventories

of raw materials or units from several processes share production

resources, the inventory and queue models should be system

models, and not models relating only to individual processes.

Such system models could be constructed using the data from

the Economic Analysis worksheet. The models could

be constructed automatically, but the current add-in does

not have this capability.

|

| |

|

|