|

|

|

Process

Flow Models |

|

-

Production Lines

|

| |

When portions

of the process are arranged into time-paced production lines,

the operation time does not entirely determine the amount of

resource time used by the operations in the line. A line is

characterized by it's cycle time, the time interval between

the departure time of units leaving the line. The operations

in a line are paced to this cycle time. When the operation

time is less than the cycle time, the resource performing the

operation remains idle for a time equal to the difference between

cycle time and operation time.

A line can accommodate operations with times greater than

the cycle time by providing parallel stations. For example,

if an operation time is 9 minutes and the cycle time is 5 minutes,

two parallel stations must be required. Each station requires

two line cycles for a unit of product.

For this case we use the time_f (time function) to

compute the extra resource time required for an operation that

is part of a production line. |

| |

|

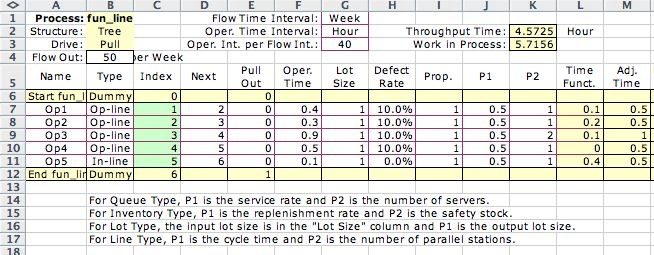

As illustrated previously, we

must choose the Time Function feature when

building the process definition.

To illustrate the use of the time

function feature, we use the example previously to show

defects, but here we assume that the processing operations

and inspection operation are arranged in a paced line.

Although the operations have different processing times,

the line is operated so that every unit of product remains

at each station for the same amount of time.

The line function is invoked by

including the word "line" as part of the Type definition

in column B below. The time function is computed in column

L. For a line operation, the function depends on the

cycle time of the line included as the P1 entry in column

J. It also depends on the number of parallel stations

provided for the operation placed in column K. For an

operation in a line with a time longer than the cycle

time, more than one station must be provided. Multiple

stations process units simultaneously. The delay in time

caused by the line operation is computed with the formula

below and presented in column L.

|

|

| |

|

|

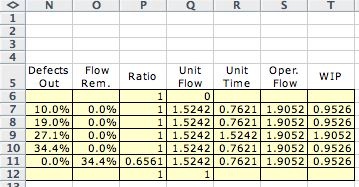

For the example, we use a cycle time of 0.5

hours. Because operation 3 has a processing time of 0.9 hours

we use two parallel stations for this operation. When a unit

passes through this operation, two cycles of the line must

pass (1 hour) before the unit is released. The function computed

in column L shows that 0.1 hour of resource time is lost.

For operations with only one station, the lost time is simply

the difference between the operation time and the cycle time.

With a demand for 50 units per week, the operation

flow is 1.9052 per hour. The WIP indicated in column T indicates

that the line has sufficient capacity to carry this load.

|

| |

|

|