|

|

|

Process

Flow Models |

|

- Downtime

|

|

There will be times

when a process experiences downtime, that is, time when the

resources associated with production becomes idle. Downtime

may be caused by a failure of a machine that causes production

to stop until the problem is located and repaired. It may also

result if some raw material is unavailable. Then production

must stop until the raw material is obtained. Usually, downtime

is disruptive and should be eliminated if possible, but a correct

model should recognize the existence of downtime.

We accommodate downtime by providing a column on the data

form. A number entered in the column for a particular operation

represents the expected downtime per unit produced. The time

is accumulated in the Adjusted Time column and ultimately

is included in the Unit Time. Downtime expends the

time available on a resource and thus reduces the time available

for useful production.

There are mechanisms that cause an entire process to go down.

Such times should be included for all operations in the process

affected. All downtimes must be expressed as expected times

per unit of production. |

| |

|

To include downtime

in the analysis, click the Downtime button on

the dialog. To keep the example simple, we do not select

the remaining options.

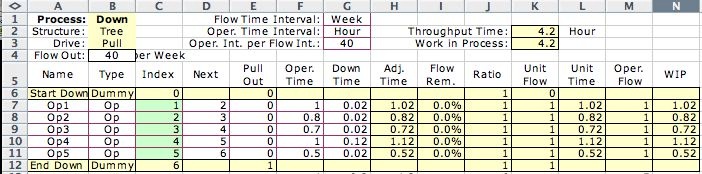

The example has five operations arranged in series.

The demand for the product is 40 per week and the operating

interval is 40 hours per week. With no losses, this results

in a flow rate of 1 per hour as shown in column M. The

operating times are shown in column F. If each operation

were implemented in a separate station, the WIP in column

N shows that all the stations average 1 or less product,

so one station for each operation is sufficient when

all downtimes are equal to 0. |

|

| |

|

|

For purposes of illustration, assume that 1%

of the items passing through the line will cause an event

that results in the entire line being shut down. Further

assume that the average downtime caused by this event is

2 hours.

With a flow of 40 per week, the expected downtime for the

system is 40*0.01*2 = 0.8 hours per week. Expressed as a

per unit amount this is 0.8/40 = 0.02 hour per unit.

A second event that occurs at a rate of 1%

of the units process, causes only operation 4 to shut down.

This downtime is 10 hours for each event. By the same reasoning

this adds an additional 0.01*10 = 0.1 hours per unit at operation

5.

The resulting downtimes are added on the form below.

|

| |

|

| |

The WIP values now indicate that a single station is no longer

sufficient for operations 1 and 4 since the values

are greater than 1 for these operations.

Not shown by this analysis is the disruptive effect of the

randomness of the downtime events. When the entire process

shuts down, the materials in process remain at the idle production

stations, so when the process restarts there is no marked

redistribution of WIP. When a single station is affected

and the other stations

continue processing, problems of supply arise when stations

downstream of the downed station become starved and inventory

piles up at the downed station. This analysis does not show

this effect.

When disruptive events concerning a single station are allowed,

inventory must be maintained to buffer the effects of downtime.

The add-in does provide an inventory option through the Time

Function feature, but the parameters of the inventory

must be externally set.

|

| |

|

|