| |

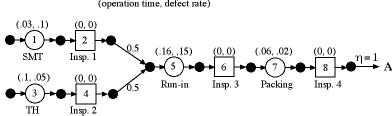

It may be that several

products are constructed using common subassemblies. We have

adapted the add-in to recognize subassemblies as raw materials.

This may reduce substantially the data required for some systems.

To illustrate we consider product A used earlier for illustration.

The product receives its inputs from two separate manufacturing

lines, the SMT line and the TH line. The process is shown below.

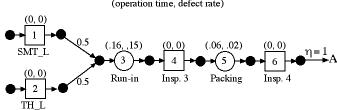

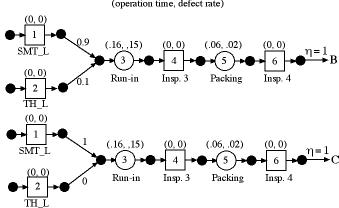

Since products B and C are the same as product

A except receiving different proportions of inputs from the

two lines, it may be more efficient to describe the processes

as below. Here we have identified a new SMT product and a new

TH product. These are subassemblies that are inputs to operations

1 and 2 respectively in the product A process. We use SMT and

TH as the product names. We use SMT_L and TH_L to identify the

process resources.

Products B and C differ only in the proportions

coming from the two lines.

It is more convenient to represent the

system as a collection of subassemblies because the details

the SMT and TH lines need not be repeated. |

Defining the Subassemblies |

| |

The figure below shows the Excel worksheet

describing process A. Note that operations 1 and 2 link to

the SMT and TH subassemblies. The link is provided by the

names in column K. The subassemblies SMT and TH are listed

as the raw materials for the first two operations.

|

| |

|

| |

The portion of the worksheet defining

the SMT and TH subassemblies appears below. The flows through

the subassemblies are not automatically linked to the processes

defined for A, B and C. Linking equations could be placed

in cells B49 and B60, however, the program does not provide

them. The linking occurs on the Project worksheet.

|

| |

|

| |

The definitions for B and C also use

SMT and TH as raw materials.

|

| |

|

| |

|

Project Worksheet |

| |

Selecting the Process Economics

item from the OM/IE menu, creates the Project worksheet.

It is similar to the worksheet without subassemblies, however,

new features are added to link the processes to the subassemblies.

We see in the Product portion of the worksheet the

table describing the economics of production. The contents

are driven by the Sales entered in column I, 200,

500 and 1000, for products A, B and C respectively. Note that

SMT and TH have no sales. Column J, however, shows the production

of these subassemblies that are required by their inclusion

in the three primary products. Column J is computed from the

Assembly matrix starting in column O. The assembly matrix

is constructed by the add-in from data defining the processes.

Column K shows the sum of the resource

operation cost and raw material cost for each product. For

products A, B and C, however, this cost does not include the

cost of the subassemblies. Column L computes the total cost

including subassemblies. Column M is the net operating profit

computed as the unit revenue less the unit total cost.

|

|

| |

Further down the Project worksheet

we find the matrices defining material and resource use. Note

that SMT and TH are listed both as materials and products

in these matrices.

|

| |

|

Mathematical

Programming Models |

| |

The mathematical programming models

must have additional variables and additional constraints

to represent the link between products and subassemblies.

The product mix model is shown below. An additional variable

is provided to allow each product to also act as a subassembly.

There is also an additional constraint for each product to

link sales to subassembly use. The solution shows the optimum

sales of each of the products and the associated subassembly

requirements.

The other mathematical programming models

are adjusted in a similar manner.

|

|

| |

Whenever

one or more products is listed as a raw material, the add-in

adjusts the analysis and mathematical programming worksheets

as indicated on this page. When no products appear as raw materials,

the subassembly adjustments are not made. |

| |

|