|

|

|

Process

Flow Analysis |

|

-

Computation for Flow Analysis |

| |

Spreadsheet formulas are included to compute

a number of characteristics associated with the process. We repeat

the data for the example together the results. The descriptions

of the results columns follow. All of the cells in the analysis

columns are colored yellow on the worksheet. The colored cells

indicate that the cells contain formulas that should not be changed

by the user. Some of the cells use functions defined by the add-in.

If a model is created on one computer and opened on another, these

functions will not compute. Use the Refresh Functions command

to rewrite the functions. Not all the results column are shown

in this example. We describe all the result columns below using

the Excel column letter for identification. |

| |

|

| |

Results

for the Process Analysis Example

Column |

Title |

Explanation |

M |

Defects

Out |

For a processing operation ("Op"),

this is the proportion of the items leaving an operation

that have defects. We assume that the defect

producing mechanisms in different operations are independent.

The function in this cell combines the probabilities

of defective parts entering the operation with the

defect probability for the operation to obtain the

probability that an item leaving the operation is defective.

The computations are implemented in the defect user-defined

function.

For an inspection operation ("In"), the

probability of a defective part leaving is zero if

the inspection is perfect, that is inspections find

and remove all defective items. If the inspection is

not perfect, the function computes the probability

that a defective item leaves the inspection.

|

N |

Flow

Removed |

For a processing operation, this

cell contains the adjusted scrap rate for the operation.

When the operation is an inspection, defective items

are removed as waste. The proportion discarded is shown

in this column. Again, these cells are computed with

a function, remove1, provided by the

add-in.

|

O |

Ratio |

This is the ratio between output

flow and input flow for an operation. When material

is removed, the ratio is less than 1 as in the example.

The ratio is also affected by the grouping factor for

the operation.

|

P |

Unit

Flow |

For this example, this is the

flow into the operation per unit flow out of the process

(out of operation 9). In general for a pull

system, there may be several operations from which

flow is removed as described by the pull out column

of the data. The unit flow is the effect of the combined

output flows from the process.

For the pull tree structure these cells are

computed with an algebraic formula based on the unit

flow of the next cell and the ratio and proportion for

the operation. For a pull network structure

the unit flows are computed with a matrix computation

using the Excel matrix inverse function.

|

Q |

Unit

Time |

This is the resource

(machine) time used by this operation per unit

of the flow out from operation 9. For the example

this is just the time used by a unit of product A.

|

R |

Operation

Flow |

This is the total flow rate into

the operation. It is the Unit Flow multiplied by the flow

out. For product A the flow out is in cell B4. The

Operation Flow is this output flow divided by the number

of operating hours per week that appears in cell G3 multiplied

by the Unit Flow.

|

S |

WIP |

This is the flow rate through the

operation multiplied by the residence time in the operation.

It is the operation flow (flow rate) multiplied

by the operation time (residence time) .

By Little's law, this must be the average work-in-process

that resides at the operation, or

the WIP.

|

|

| |

In column K near the top of the display

we see two computed quantities. Cell K3 computes the total

WIP in the process. It is the sum of the operation WIP values

appearing in column S of the process display. Cell K2 holds

the total WIP divided by the total flow rate out of the process.

For the Pull system, the total flow rate out of the process

is the sum of the external flows from column E of the data

multiplied by the contents of cell B4. When the operations

are arranged in a series system it is the average time interval

between when raw materials enter the process and when the

finished good leaves the process. Sometimes we call this the

cycle time. When the structure is more general than a series

system, it is the average time materials remain in the system.

|

| |

|

| |

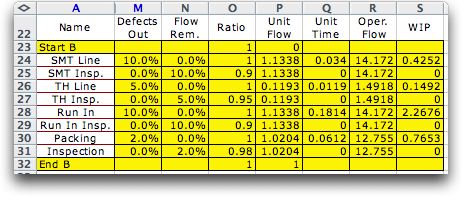

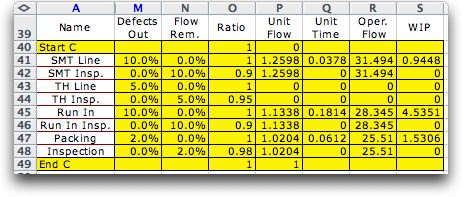

The process results for products B

and C are below.

|

| |

Results

for Process B

Results for Process C

|

| |

|

|