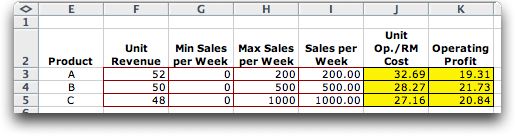

Product Information

|

Range |

Title |

Explanation |

E3:E5 |

Product |

These cells hold the names of the processes. We

associate the output of each product with the process.

The name of the product is the name of the process.

These names are compiled from the process names in

the workbook. They should not be changed. |

F3:F5 |

Unit

Revenue |

This is the revenue

realized per unit of sales for each products. |

G3:G5 |

Min

Sales |

This is the minimum

number of units sold per week for each product. |

H3:H5 |

Max

Sales |

This is the maximum

number of units sold per week for each product. |

I3:I5 |

Sales |

This is the number

of units sold per week for each product. The user

may experiment with these values. The specific

values shown here are those provided by the flow

out entries for the products. When a mathematical

programming model is constructed and run the computed

results will replace these entries. In that case

the range will be colored yellow. |

J3:J5 |

Unit Operating/Raw

Material Cost |

This is the sum of the unit

operating cost for the resources used by the process

and the cost of the raw materials expended for

a unit of product. |

K3:K5 |

Unit

Profit |

This is a computed

number that is the unit revenue minus the raw material

and resource costs for a unit of product. |

|

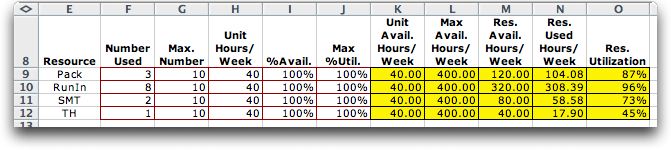

Resource Availability Information

|

Range |

Title |

Explanation |

E9:E12 |

Resource |

These cells hold the names

of the resources. The add-in compiles a list of

resources from those named in the Resource

Type columns of the processes. General resources

also are included in this list. The list is compiled

by the add-in and should not be changed. |

F9:F12 |

Number

Used |

This is

the actual number of resources (machines) used

of each type. |

G9:G12 |

Max Number |

This is the maximum number

of resources (machines) that can be used. |

H9HI12 |

Unit

hours/week |

This is the number

of hours each machine type is available during

a week. The number 40 indicates one 8-hour shift

per day and a five day week. Two shifts per day

would be indicated with 80 in this cell. |

I9:I12 |

%

Available |

This is the percent

of time each machine is available for productive

activities. The number might be less than 100%

due to downtime for maintenance, worker break times,

etc. |

J9:J12 |

%

Maximum Utilization |

This is the percentage

of the available time that the machine is to be

active. This number might be set less than 100%

to allow for statistical variability. |

K9:K12 |

Unit

Available hours per week |

This is a computed

field that indicates the maximum number of hours

one unit of a machine type can be used during a

week. It is the product of the previous three columns. |

L9:L12 |

Max. Available

hours per week |

These entries multiply the Max.

Number by the Unit Availability. |

M9:M12 |

Resource

Available hours per week |

These entries multiply the Number

Used by the Unit Availability. |

N9:N12 |

Resource

Used hours per week |

This is the numbers of hours

used on each resource type for the specified level

of sales (I3:I5). For the example, the time used

on Run-In is more than the amount available.

This is clearly a bottleneck resource. When the

time used is greater than the time available, the

sales quantities are not feasible. |

O9:O12 |

Utilization |

This is the proportion of

the time available that the resource is used. It

is the entry in row N divided by the amount in

row M. |

|

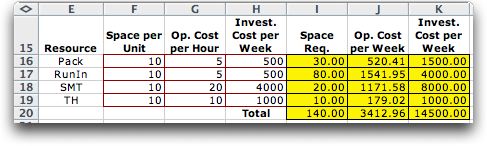

Resource Space Information

|

Range |

Title |

Explanation |

E16:E19 |

Resource |

These cells hold the names

of the resources. The add-in compiles a list of resources

from those named in the Resource Type columns

of the processes. General resources also are included

in this list. The list is compiled by the add-in

and should not be changed. |

F16:F19 |

Space

per Unit |

This

is space measured in some squared space dimension.

The data is useful for a plant layout analysis. |

G16:G19 |

Operating Cost

per hour |

This is the cost to operate

the resource per hour. |

H16:H19 |

Investment

Cost per week |

This is the investment cost

per week. It is used when the number of machines

is to be optimized. The time dimension for the operating

cost and investment cost are the same. |

I16:I19 |

Space

Required |

This

is computed by multiplying the Space per Unit by

the Number Used (F9:F12). |

J16:J19 |

Operating

Cost per Week |

This is computed

by multiplying the Operating

Cost per Hour by the Resource

Used (N9:N12). |

K16:K19 |

Investment

Cost per Week |

This is computed

by multiplying the Investment

Cost per Week by the Number

Used (F9:F12). |

|

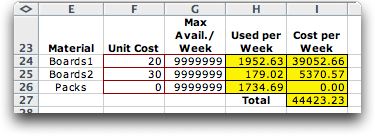

|

Range |

Title |

Explanation |

E24:E26 |

Material |

These cells hold the names of the materials. The

add-in compiles a list of materials from those named

in the Raw Materials Type columns of the processes.

General raw materials also are included in this list.

The list is compiled by the add-in and should not

be changed. |

F24:F26 |

Unit

Cost |

This is the unit cost for purchasing

the raw materials. |

G24:G26 |

Maximum Available |

This is the maximum number of units of raw materials

available per week. |

H24:H26 |

Used |

This is the numbers of units used for each raw

material type for the specified level of sales (I3:I5). |

I24:I26 |

Cost |

This

is computed by multiplying the Space per Unit by

the Number Used (F9:F12). |

|

|

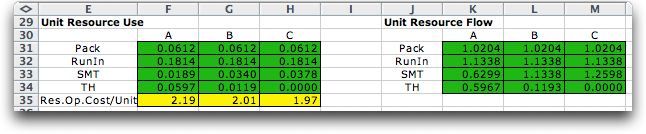

This

information is produced entirely by the computer from

the process definitions. No data is entered by the user.

The entries from the Unit Resource Use matrix

come from the unit time columns of the process

definitions. When a process uses a resource more than

once, the unit times are added. The entries from the Unit

Resource Flow matrix come from the unit flow columns

of the process definitions. When a process uses a resource

more than once, the unit flows are added.

Range |

Title |

Explanation |

F31:H34 |

Unit

Resource Use |

This

is the number of hours required for on each resource

for each unit of finished good for a process. |

F35:H35 |

Resource

Operating cost per unit |

This

is operating cost associated with each resource

type per unit of product. It is included in the

unit profit computation. |

K31:M34 |

Unit

Resource Flow |

This is the

number of arrivals at each resource for each unit

of finished good for a process. |

|

|

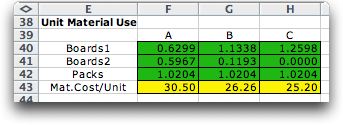

This

information is produced entirely by the computer from

the process definitions. No data is entered by the user.

The entries come from the raw material amount and

the unit flow columns of the process results.

When a process uses a resource more than once, the results

are added.

Range |

Title |

Explanation |

F40:H42 |

Material

used per unit of product |

This

is the number of units of raw material required for

per unit of flow out for each process. |

F43:H43 |

Material

cost per unit |

This

is material cost associated with per unit of product.

It is included in the unit profit computation. |

|

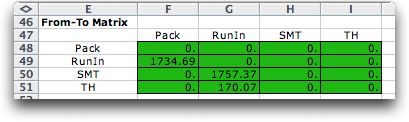

From-To

Matrix

|

The

from-to matrix accumulates flows between adjacent resources

in the process definitions. The matrix is useful for

plant layout analyses. In order for an entry to appear

there must be resources defined for each of two adjacent

operations. If adjacent operations have the same name,

the flows are not accumulated. Thus we have zero flows

on the diagonal. The flow is the sum of the flows for

all three products. The Run-in resource is specified

for the Run-in operation and flow enters this operation

from both the SMT and TH Lines. We see these entries

in the column labeled RunIn.

|

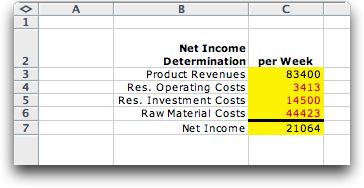

Summary Information

|

Information

on the upper left corner of the Project worksheet shows

the components of net income for the sales volumes specified.

|

|

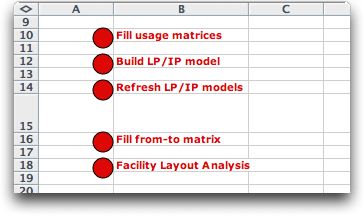

Below

the summary information, we see four buttons that control

the computations of the add-in.

The top button fills the resource and raw material usage

matrices on the Project worksheet. These matrices are

filled when the worksheet is first constructed, but when

the user changes the definitions of the projects the

entries should be recomputed. If the sets of products,

resources or raw materials has changed, it is necessary

to completely reconstruct the Project worksheet. Economic

data previously entered is transferred to the new worksheet.

The second button creates a worksheet defining one

of three mathematical programming models that can be

used for product mix, raw material and resource decisions.

The models are discussed elsewhere in

these pages.

The third button refreshes the LP/IP models that are

in the workbook. These models depend on the economic

and process flow data and when this data is changed,

the models should be refreshed.

The fourth button fills the From-To matrix. Again this

only necessary when the data changes.

The bottom button calls the Facility

Layout add-in and places the space and flow data

into the layout data ranges.

|

|