|

|

|

Process

Flow Analysis |

|

-

Process Definitions |

| |

A manufacturing system

is defined by collection of processes for the one or more products

of the system. Data describes a process in terms of structure,

operation sequence, push or pull flow, setup and operation times,

lot sizes, recycle rates, scrap rates, defect rates, raw material

use and machine requirements. Computations distinguish between

processing and inspection operations, with processing operations

producing defective items, and inspection operations discovering

and scrapping defective parts. The main results of the add-in

are the operation unit flows that indicate the rate of flow

into each operation per unit of finished product. The add-in

builds and formats the worksheet areas necessary for data entry

and inserts the formulas necessary for analysis.

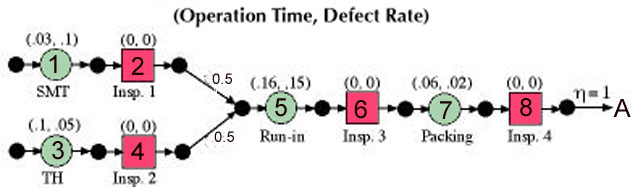

We repeat the process chart for product A for illustration.

Data concerning product A is entered

by selecting the Add Process item from the OM_IE menu. The following

dialog box is presented. Cells are provided for the Location

and Name of the process. The check boxes indicate various

features the data structure is to exhibit. For the present example,

we include defects, proportions, resources and raw materials.

The Tree structure option has been chosen because the

the raw materials combine to make the finished good. The process

chart has the tree structure. The Pull drive option indicates

that the demand for the product is pulled from the final operation.

The other structure and drive options are illustrated later.

|

| |

|

| |

The figure below shows the data structure

after the information for product A has been entered. The

other products differ only in the proportion of cards passing

through the two lines. Note that the columns of the display

include the required columns and columns necessary to model

the items checked in the dialog box.

At the top of the display the name,

structure, drive and flow out of the

process are listed. The first three items are in a yellow

field indicating that these values should not be changed.

If they are mistakenly entered, delete the process and redefine

it with correct values. The flow out can be changed to reflect

different amounts of finished products. The data entries in

cells G1, G2 and G3 define the time dimensions for characteristics

of the problem. The Flow Time Interval is the dimension

by which demand for the finished good is measured. For this

example, the flow out of the process is 200 units per week.The

Operating Time Interval is the dimension by which

processing times are measured. For example the processing

time for the SMT line is 0.03 hours. The Operating Interval

per Flow Interval, tells for this example the number of processing

hours during a week. We enter 40 here to indicate one shift

operation for 5 days per week.

|

| |

|

| |

Also at the top of the display are

summary results. In cell K1 we see the total time spent in

the operations of the process measured in hours. Cell K2 holds

the total Work-in Process for this process. The contents of

these cells are computed with formulas as described below.

The table below shows the meanings

of the various data columns. We only define here the columns

used in the example. The data columns start in the worksheet

column A in the example, and we use the Excel column designations

to describe the items. There is no requirement, however, that

the process definitions begin in column A, and the columns

used by a particular data item will depend on the items selected

in the dialog.

|

| |

Data

Items Describing a Process

Column |

Title |

Explanation |

A |

Name |

Name to identify operation.

The example has eight operations. The Start and End operations

are added by the program.

|

B |

Type |

The type is identified by the first

two letters of this field. "Op" identifies

a processing operation, delay or inventory. Defects introduced

in "Op"

operations are accumulated but not discarded. "In" identifies

an inspection operation. "In" operations discard

some proportion of the defects as waste.

|

C |

Index |

This column specifies a unique

number identifying an operation. The column is colored

green to indicate that the add-in controls its contents.

The numbers in this column will be sequential integers

and the index assigned to a particular operation will

change when operations are added or deleted using the Change

Process command. The

user should not bother these numbers.

|

D |

Next |

This column gives the index of

the following operation in the process. For the pull/tree

option illustrated here all operations must have a unique

following operation. The following node of the "End" operation

is 0. Every pull/tree structure defines a unique vector

of Next indices. This column is labeled Previous for

a push tree. For the Network structure, this

column will not be included unless the Defects option

is selected on the dialog.

|

E |

Pull Out |

The numbers in this column describe

flows out of each node relative to 1. For the example,

the only non-zero entry is the end operation (9). The

total flow out of the process is the product of this

number and the number in cell B4. Other numbers

in this column are also relative. If 1/2 were entered

in E10, flow in the amount of (1/2) times the number

in cell B4 would be removed from the TH line. This allows

the process to have several outputs. Note that all outputs

are proportional to the number in B4.

|

F |

Operation Time |

This is the time to process one

item passing through the operation.

|

G |

Defect Rate |

This is the percentage of products

passing through a processing operation that receive defects.

We assume a single defect warrants discard of an item,

however, the defects are only discovered by an inspection.

Defects do not change the flow except at an inspection

operation. For an inspection operation, the defect rate

is the proportion of defects not discovered and

discarded.

|

H |

Proportion |

For a pull system, this

is the proportion of the flow entering the next node

that comes from the operation specified by this data

line. For product A, 50% of the flow of finished product

comes from the SMT Inspection and 50% of the product

comes from the TH Inspection. The other products differ

with respect to these proportions. For a push system,

this parameter is the proportion of the flow leaving

the operation that goes to the next operation.

|

I |

Resource Type |

This is the machine resource

used by the operation. Machines are identified with

names or numbers. Different operations and processes

may use the same resources. The resource types are

used to construct the from-to matrix. See

the page describing this matrix for more details.

|

J |

Resource Amount |

This is the number of resources

used by the operation. For machines it is usually 1.

For those rows without resources, the number has no meaning.

|

K |

Raw Material Type |

This is the raw material identifier

used by the operation. Raw materials are identified with

names or numbers. Different operations and processes

may use the same raw materials.

|

L |

Raw Material Amount |

This is the number of units of

raw material used by the operation. It has no

meaning if the associated Raw Material Type is blank

or 0.

|

|

| |

The example includes two additional

products, B and C. The products differ in the proportion of

product that passes through the SMT and TH lines. In the case

of B, 90% of the boards come through the SMT line, while 10%

come through the TH line. All of the boards for product C

come through the SMT line. The TH portion of the process could

have been left out, but we leave it in to keep the three processes

similar.

|

| |

|

| |

|

| |

Note that we have defined all the processes

in the example on the same worksheet with all process definitions

starting in column A. This is not necessary as processes may

be defined on different worksheets and at different locations

within a worksheet. All the processes are assumed to comprise

the complete system for the economic analysis. Use a different

workbook for each system.

There is no limit to the number of

operations in a process for the tree structure. The network

structure is limited to about 50 operations. The analysis

of the network structure requires a matrix inversion. Excel

limits that computation to a matrix with fewer than 50 rows

and columns.

The add-in limits the number processes,

resources and raw materials to 50 for each. These numbers

may be changed by changing the associated variables in the

Declaration module of the add-in.

|

Change Process |

| |

Operations

may be added or deleted with the Change Process item

on the OM_IE menu. The example below will add a new operation

after the operation indexed 1 (SMT Line). The start and end operations

are fixed. Operations cannot be added before the start or

after the end. Use the third button

to delete an entire process.

|

| |

|

|