|

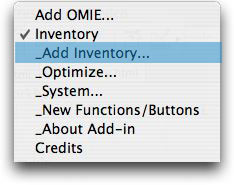

To create a model choose Add

Inventory from the menu. The dialog below is presented. |

Near the top of the dialog

we see the address of the worksheet cell where the top of

the inventory definition will be placed. The Name entered

here is used for naming ranges. The Time Interval defines

the interval used for all rates and time intervals. The Replications

box allows several inventories to be simultaneously

created.

Buttons on the dialog determine the type of model to be created.

The Type buttons determine what kind of inventory is

to be modeled. The Storage inventories are discussed

on the majority of pages in this section of the site. The other

options are for WIP and are discussed on the Work-in-Progress

and Systems pages. The Replenishment Rate

buttons determine if the inventory is to be replenished

by a finite rate process or whether the entire inventory quantity

arrives instantaneously (at an infinite rate). The former case

is appropriate if a manufacturing process provides materials

to the inventory and the latter case is appropriate when a batch

delivery occurs.

Buttons under the Shortages label determine if shortages

are allowed and their effect on the system. We illustrate the

no shortages case here.

When the Quantity Discount button is checked and more

than one replication is specified, the add-in constructs a model

that determines the optimum when discounts are offered for larger

purchases.

The Demand box determines if the product is demanded

from the inventory at a deterministic rate or whether it is

governed by a probability distribution. We illustrate the deterministic

case here and will discuss the stochastic options later.

The Shortage Cost area specifies how shortages affect

the cost of the inventory. Since no shortages are allowed for

this example, the buttons are disabled.

The Params button presents a

new dialog, illustrated below. The dialog allows direct entry

of the parameters associated with the inventory model. The example

shows the default values. The boxes related to stochastic parameters

and shortages are not available because the current model is

deterministic and allows no shortages. Parameters entered with

this dialog are placed on the Excel worksheet. They may be changed

arbitrarily once the model is created, so it is really unnecessary

to set the parameters here.

The Display button on the Inventory definition

dialog presents another dialog with buttons that determine which

results are presented on the worksheet. In some cases the student

may wish to show only a few. The boxes under Instance

will add worksheet rows that compute the items for design variables

specified by the student. Boxes under Optimum will

add rows that compute the optimum results.

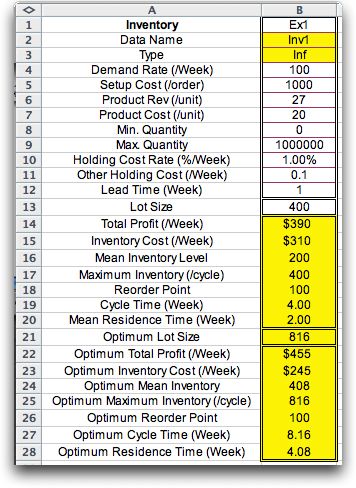

The figure below shows the entries placed

on the worksheet by the add-in. Although the display can appear

anywhere on the worksheet the example is placed in columns A

and B. The titles are in column A and the data and results are

in column B. Four kinds of information appear in the display.

They are separated by the double outlines.

Parameters

The first part of the display holds the

parameters of the model. The number of rows used

depends on type of model. For the example the parameters

are in rows 1 through 12. The first entry is set

by the user to identify the inventory. The other

parameters may be changed except the Data Name

and Type. The data name is used to name

cells on the worksheet. The type is used by the

program and should not be changed. All numeric parameters

are to be nonnegative. |

Instance Variables

For the example there is only instance variable the

lot size in cell B13. For models involving shortages

we also specify the fill rate. For stochastic models

there is an entry for the reorder point. |

Instance Results

These are all computed by functions provided by the

add-in. Cells B14 through B29 are colored yellow to

indicate that their contents should not be changed.

The cells hold functions that depend on the parameters

and the instance variables. Changing the instance

variables causes the formula results to change. |

Optimum Results

These are computed in cells B22 though B28. Again,

the yellow color indicates that the cells contain

formulas and should not be changed. The optimum results

depend on the parameters. Changing the parameters

will result in new optimum results. |

|

On this and the following pages, we consider the several models

that are available and explain the meaning of the parameters

and results for each model. |