| Infinite Replenishment

Rate and Backorders |

| |

In these

models, we allow the inventory to go to 0 some time before replenishment.

There are two assumptions regarding the response of a customer

to the unavailable item. The first response is that the customer

will accept later delivery. This is called a backorder. We provide

three cost models for the backorder case:

- There is an expense for each cycle in which a backorder

occurs. This cost is independent of the number of backorders.

The expense is measured in $.

- There is an expense for each backordered item. This cost

is independent of the time the customer must wait for delivery.

The expense is measured in $/unit.

- The expense for each item is proportional to the time the

customer must wait. For a particular cycle the total cost

is proportional to the integral of the shortage amount during

the cycle. The expense is measured in $/unit-time.

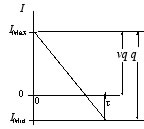

The figure below illustrates on-hand inventory

in blue and backordered quantities in red.

Since replenishments are instantaneous, backordered

items are delivered at the time of replenishment and these items

do not remain in inventory. We signify backorders as a negative

inventory, so the minimum inventory is a negative number. The

difference between the minimum and maximum inventory is the

lot size. |

Notation |

| |

When shortages are

allowed, several new quantities must be defined and several

reinterpreted.

• Backorder cost: When a customer seeks the product and

finds the inventory empty, the demand can either go unfulfilled

or be satisfied later when the product becomes available. The

former case is called a lost sale, and the latter is called

a backorder. We consider the lost sales cost later. The total

backorder cost depends on the measured adopted for backorder

cost.

• Backorder level: This is the average level of backorders

over time. It is the average area of the red areas in the figure

above.

• Fill Rate(v): This is the proportion of the

customers served directly from the inventory. The proportion

of the customers who must wait for a backordered item is 1 -

v. We use this factor as a design variable when shortages

are allowed. For the backordered case the service level is I_Max/q.

• Maximum inventory level (I_Max): Many books

call this quantity the order level. When backorders are not

allowed, this quantity is the same as q. When backorders

are allowed, it is less than q. (units)

• Minimum inventory level (I_Min=I_Max-q): When

backorders are not allowed, this quantity is 0. With

backorders its absolute value is the level of maximum number

of backordered units. (units)

• Mean Residence Time: This is the time a remains in

inventory, given that it is placed in inventory. With shortages,

not all units appear in inventory. Those units that are backordered,

go to the customer as soon as they are available. For the infinite

replenishment rate case, this is when an order arrives. We compute

the mean residence time using Little's law by dividing the average

inventory level by the rate of items entering inventory. This

rate is D(1 - v).

• Mean Backorder Time: When an item is backordered, a

customer must wait for a period of time before the backorder

is satisfied. Again we use Little's law. For the mean backorder

time, we divide the average backorder level by the rate of items

being backordered. |

Single Cycle |

| |

|

The results of the analysis

depend on the lot size and the service level. The figure

shows that the maximum inventory is the same as the order

level. In addition to the other results computed for

the no-shortages case we now can compute:

- Minimum inventory level: This is vq - q.

- Maximum inventory level: This is vq.

|

|

The Inventory Model |

| |

|

As before, we create a model

by selecting Add Inventory from the menu. We select

Allowed from the Shortages frame on the

dialog. We select per unit-time as the Shortage

Cost measure. |

|

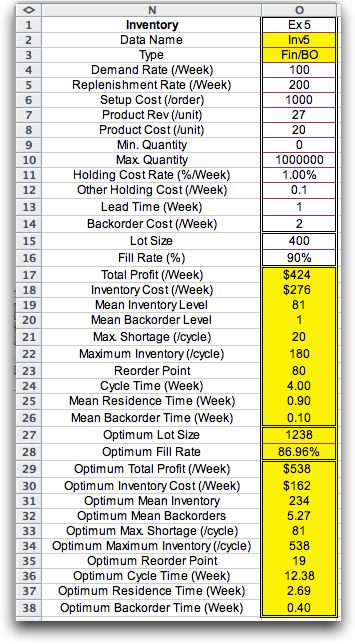

The results for this case

using a backorder cost of $2 per unit-week is shown at

the left. For the evaluation of an instance we choose

a lot size of 400 and a service level of 90%.

The optimum lot size is greater, 876, and the optimum

fill rate is 86.96%. The optimum solution balances ordering,

inventory and backorder costs. |

|

Infinite Replenishment

Rate and Lost Sales |

| |

A second

response of the customer to an inventory stock out is for the

customer to leave without purchasing the product. This is a

Lost Sale. The cost of a lost sale is measured in $

per unit. The cost should be at least the lost profit from the

sale, but will probably be greater due to penalty costs and

to loss of good will from the disappointed customer.

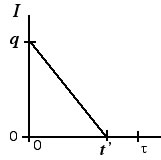

The figure below illustrates the on-hand inventory

in blue. The inventory reaches 0 before the end of the cycle,

but no shortage is shown since a shortage is never recovered.

The lot size is the maximum inventory level.

|

Notation |

| |

The shortage cost

has a different meaning with lost sales.

• Lost sales cost: When a customer seeks the product

and finds the inventory empty, the demand goes unfulfilled in

the lost sales case. In this case the shortage cost is the lost

profit of the lost sale plus any other any costs associated

with the lost sale. ($/unit-time)

• Order level (q): The maximum level reached

by the inventory is the order level. With lost sales, the order

level is q. (units)

• Fill rate (v): This is the proportion of the

customers served directly from the inventory. The proportion

of the customers that are lost is 1 - v. We use this

factor as a design variable. |

Single Cycle |

| |

|

The results of the analysis

depend on the lot size and the service level. The figure

shows that the maximum inventory is the same as the order

level. In addition to the other results computed for the

no-shortages case we now can compute:

- Maximum inventory level: This is q.

- Minimum inventory level: This is 0.

- Service Level: This is v. The satisfied

demand in a cycle is Dt', where t' = v*(cycle

time).

|

|

The Inventory Model |

| |

|

As before, we create a model

by selecting Add Inventory from the menu. We

select per lost sale from the Shortage Cost

options frame on the dialog.

|

| The lost sales case is interesting because

the optimum solution is to allow no shortages or to satisfy

none of the demand. The two cases are below for an example.

On the left, Ex4 A, when the unit cost of a lost sale is

$3, the optimum policy is the same as the policy when no

shortages are allowed. In the case at the right, Ex4 B,

when the lost sales cost is $2, the optimum policy has the

lot size and service level both at 0. The optimum cost is

the cost when all demand is lost. We have modified the example

for this illustration by setting the product revenues and

costs both to zero. The lost sales cost represents the net

revenue loss on a sale plus any additional penalties due

to the lost sale. |

|

Finite Replenishment

Rate and Backorders |

| |

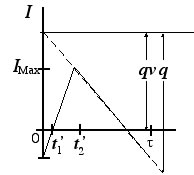

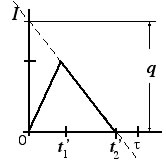

The figure

below illustrates this case. On-hand inventories are in blue

and backordered quantities are in red.

No new notation is required for this case. |

Single Cycle |

| |

|

At the start of the cycle,

the inventory grows at the rate P - D until the

lot size is produced and then declines at the rate D.

From time 0 to t1' the production is satisfying backorder

demand and current demand. From t1' to t2' production

adds to inventory. From t2' until the end of the cycle,

the inventory decreases at the demand rate D. |

|

The Inventory Model |

| |

|

As before, we create a model

by selecting Add Inventory from the menu. We

select Finite from the Replenishment

options and per unit-time from the Shortage

Cost options on the dialog.

|

|

The results depend on both

the lot size and fill rate.

The optimum solution balances order cost, inventory cost

and backorder cost. |

|

Finite Replenishment

Rate and Lost Sales |

| |

The figure

below illustrates this case. Inventories are blue. Since shortages

are lost there is no backorder region.

No new notation is required for this case. |

Single Cycle |

| |

|

At the start of the cycle,

the inventory grows at the rate P - D until the

lot size is produced and then declines at the rate D.

From time 0 to t1' the production is satisfying current

demand and building inventory. From t1' to t2' inventory

decreases until it reaches 0. From t2' until the end of

the cycle, the inventory remains at 0 while sales are lost. |

|

The Inventory Model |

| |

|

As before, we create a model

by selecting Add Inventory from the menu and

select the appropriate options

Again we see the result that the optimum either has no

shortages or satisfies none of the demand. With a shortage

cost of $2 per unit, the optimum policy is to allow no

shortages as shown on the left. With a cost of $1 per

unit, no inventory is maintained as shown on the right. |

|

| |

|