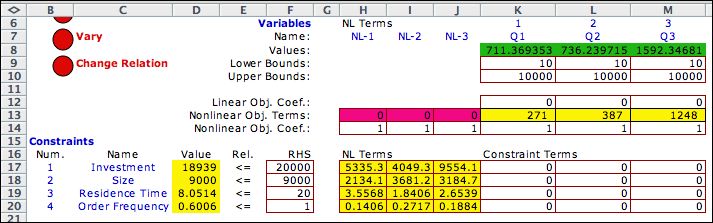

The mathematical programming

model is placed in the first 20 rows of the worksheet and the

range for the inventory data is placed below, starting in row

23 for the example. The cells in rows 23 through 33, excluding

rows 24 and 25, can be changed to reflect the data for the problem.

The specific data included depends on the type of inventory

defined by the dialog. In the example, we have chosen to have

an infinite replenishment rate and allow no shortages. The data

for the items has been selected for illustration.

Row 34 holds the lot sizes for the items. These cells have

formulas that link their contents to the math-programming solution

in row 8. The contents in these cells, as well as other yellow

cells, should not be changed. They all hold Excel formulas.

Rows 35 through 39 hold functions provided by the add-in that

compute quantities necessary for the constraints or objective

function of the math-programming model. They all depend on the

lot size in row 34.

The nonlinear programming model is repeated below for convenience.

The variables for the model are the lot sizes

of the three items. We use 10 as the lower bound and the default

of 10000 for the upper bound. The lower bound is chosen to keep

the lot size from going to zero, where some of the functions

are undefined. The objective is to maximize net profit for the

system. The linear coefficients are zero for this application.

The nonlinear objective function terms all point to row 35 of

the inventory definition where the profit for each item is computed.

We have selected four constraints for the example.

The nonlinear terms for the inventory items appear in the

yellow cells of columns H through I. The constraint

values depend on the lot sizes and are computed in the Value column.

The restrictions on the quantities are provided by the user

and are listed in the RHS column. The model requires for each

constraint that

Value <= RHS.

- Investment: This constraint restricts the average inventory

investment for the system. The yellow areas for this constraint

hold formulas that multiply the item costs (row 29) by the

mean values of the inventories (row 36). The sum appears

as the quantity under the word Value. It is limited

by the number in the RHS cell to 20,000. The constraint

is loose for the optimum solution.

- Size: This constraint restricts the maximum space or size

of the inventory. The yellow areas for this constraint hold

formulas that multiply the item sizes (row 32) by the maximum

values of the inventories (row 37). The total size appears

as the quantity under the word Value. It is limited

by the number in the RHS cell to 9,000. This constraint

is tight.

- Residence Time: This constraint restricts the weighted residence

times for the items. The yellow areas for this constraint hold

formulas that multiply the weights (row 33) by the mean residence

times (row 39). The sum appears as the quantity under the

word Value. It is limited

by the number in the RHS cell to 20 weeks. This constraint

is loose.

- Order Frequency: This constraint limits the number of replenishment

orders per time interval (per week for the example). The yellow

areas for this constraint hold the inverses of the cycle times

(row 38). The sum appears as quantity under the word Value.It

is limited by the number in the RHS cell to 1 per week. This

constraint is also loose.

Clicking on the Solve button automatically calls the Excel

Solver, loads the model and initiates the solution procedure.

Be sure to open and close the Solver dialog before

using this button. If the model was created on a different computer,

use the New Functions and Buttons command on the menu

to create a new button.

Since this is a nonlinear programming model, the solution may

not converge to a globally optimum solution. Try several different

starting points for the variable values in row 8, and choose

the solution with the greatest profit. There is no guarantee

that the global optimum will be obtained by this process, but

it improves the chance that a good solution will be found. |