The Inventory

add-in also has a function to estimate average Work in Progress

(WIP) for components of a system. The general call to this

function is written as below with two arguments.

Inv_WIP(instance As Range, inventory

As Range)

Both arguments are ranges. The instance is a range

that specifies the variables controlling the component. The

range inventory holds the parameters associated with

the component that are necessary to compute the WIP and related

results.

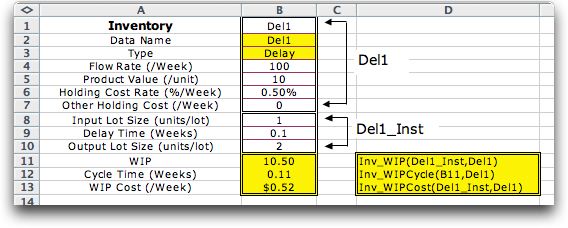

Several different types of components are

analyzed by the same function. The worksheet below shows the

results a delay, one of the simplest of the components. The inventory range

is B1:B7 and has the name Del1. The type of the component is

in B3, Delay. The WIP functions interpret the remainder

of the range based on this type. The instance range

is B8:B10 and has the name Del1_Inst. The controlling variables

are the input lot size (1), the delay time (0.1 week) and the

output lot size (2).

The WIP for this component is computed by the function is

cell B11.

= Inv_WIP(Del1_Inst,Del1)

An alternative entry would enter the ranges explicitly.

= Inv_WIP(B8:B10,B1:B7)

Although the data is arranged by column here,

the function also accepts a row orientation. The value, 10.50,

is the average level of WIP inventory caused by this delay.

Two other WIP related quantities are computed in the example

with two additional functions. The first computes the average

residence time, which is typically called cycle time in WIP

analysis. The second computes the holding cost associated with

the WIP. General call statements are below.

Inv_WIPCycle(Inv_L, inventory As Range)

Inv_WIPCost(instance As Range, inventory

As Range)

The first argument of the Inv_WIPCycle function

is a pointer to the cell holding the average WIP.

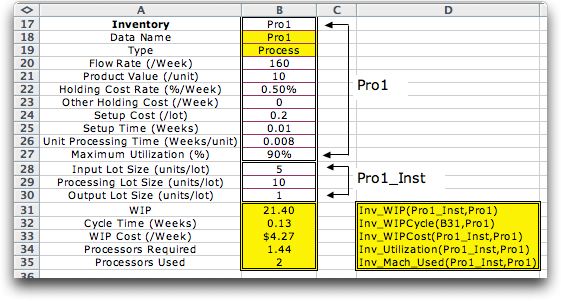

The figure below illustrates another component

type, Process, which represents a processing operation

in a manufacturing system. Although the call statements the

WIP functions are the same, the inventory range is

larger for this component to accommodate parameters relevant

to a processing operation. The instance range still

has three cells, but the middle cell, B29, now shows the processing

lot size.

The results of the WIP function appear in cells

B31 through B35. Two new functions are introduced here to compute

the processor utilization and the integer number of processors

required to accommodate the flow. The general call statements

show that have the two range arguments.

Inv_Utilization(instance As Range,

inventory As Range)

Inv_Mach_Used(instance As Range, inventory

As Range)

Although Excel formulas or functions can implement

special cases of the results, we use functions to provide generality.

Because the functions use all the data and variables associated

the system, they can be used without the data forms constructed

by the add-in.

The WIP functions recognize seven different types

of components as illustrated in the figure below. We show with

x's data that is irrelevant for certain of the components.

The middle cell of the instance variables has different

meanings for the different components. The Change component

does not use the middle cell. |