|

The line is a series of operations that all carry the same

flow. For the push line, the flow is enters the first operation

and passes through the line to the last one. We show as an example

a line with five operations with flow pushed from the first.

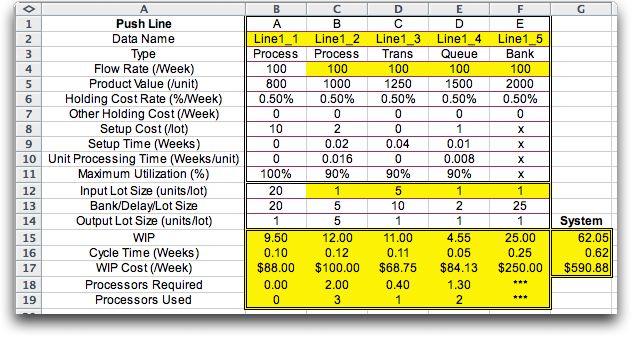

The Excel worksheet for a numerical example is shown below.

Note that the titles in the display are more general than for

individual operations since the columns of the system display

represent different kinds of operations. Row 1 holds the operation

names provided by the modeler. Row 2 holds the name used for

named ranges created by the computer. These entries should not

be changed. Row 3 defines the types of operation. The types

available are the WIP component types

described previously. The program uses the first 3 letters to

identify the type.

Rows 5 through 11 hold data describing the individual operations.

We have created a hypothetical situation for our example.

The push line has all flows determined by the flow rate entry

for operation A, cell B4. This cell has a white background indicating

that it is under the control of the modeler. The cells to the

right in row 4 are colored yellow to indicate that they are

determined by formulas. The flow formula makes the cell value

equal to the value of the cell on the left.

Operation A represents the raw material ordering process where

the lot size is 10 units. The material passes through process

B with nonzero setup time and unit processing time. To reduce

the effect of the setup time we produce lots of 5 units. We

then pass to the transportation operation, C. The setup time

in this case is the fixed time to move 10 items. We move lots

of size 10, but then separate the lots into individual items.

Operation D is a process with a queue. Although we are assuming

a constant flow rate, the queuing models assume variability

in the arrival and service activities. Operation D processes

lots of 2 and then sends individual items into operation E.

Operation E is the finished goods inventory. The policy is to

have an average of 25 units in this inventory, represented as

a bank. The bank operation, E, has data items indicated

by x. The numbers in these cells do not affect the results.

Row 5 holds the unit values. For a line system, the values

increase as the product passes through the line. The difference

between the value at an operation and the value at its predecessor

is the value added by the operation.

|