|

|

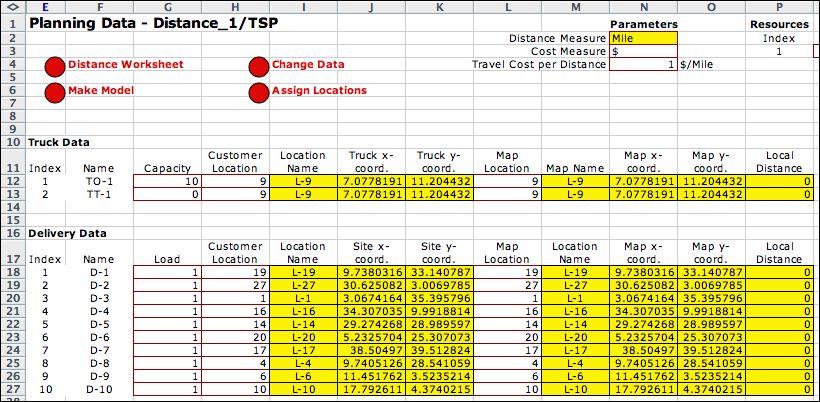

This page investigates the various

options for problem complexity. The examples of this page are

on the routing_demo.xls file. The figure below shows

the distance and customer

lists for all the examples except the last one. We keep the

problems small to more easily show the features of the worksheets

created by the add-in. In this case the customer and distance

locations are the same. The last example on this page shows

a case where they are different.

|

TSP Considering only Distance |

| |

Plans are constructed by clicking

the Make Plan button on either the distance or the data

sheet. The dialog shown below accepts a name for the plan, TSP

for the example. Fields are provided to specify the number of

deliveries, trucks and resources. When clicked the Random

Data checkbox calls a random number generator to choose

the parameters of the problem. The seed controls the sequence

of random numbers generated.

The two checkboxes at the bottom specify the

structure of the model. Leaving both options unchecked, we build

a model that does not include time or time windows. |

| |

|

| |

Clicking OK builds the planning

data worksheet shown below. Column H holds indices to the customer

list. The truck is represented by two entries, one for the

origin location of the truck and one for the terminal location.

Here we assign customer location 9 to both. The location name

and coordinates are passed to this worksheet from the customer

worksheet via Excel formulas.

The map locations are assigned in column L. In general, these

may be different than the customer locations, but when the

distance and customer worksheets have the same location lists,

a customer is assigned to the same map index

as customer index. The location name and coordinates are transferred

by equations from the distance worksheet. The local distance

in column P is the distance from the customer location to the

map location. Since the example has these co-located, the local

distance is zero.

The only resource used for the example is truck capacity.

The numbers in column G give the capacity values for the trucks

and the loads for the deliveries. Loads subtract from the capacity,

so this constraint is not affective for the TSP example. |

|

| |

We more formally list the columns

of the planning

data worksheet below. The TSP model is the simplest type, additional

columns are added for the time and time window options.

| Name |

The default names are assigned as in the example, but can

be changed to identify specific vehicles and delivery points.

Two entries are required for each truck representing its

starting location, TO-1, and its terminal location, TT-1. The

letter O stands for origin, and the letter T stands

for terminal. Each truck occupies two rows of the

table, even numbered rows are out-going and odd numbered

rows and in-coming. |

| Capacity/Load |

The first resource constraint is automatically named the

capacity. The loads associated with the delivery sites use

the capacity of a truck. The default load for each site is

1 and the default capacity of each truck is the total load

divided by the number of trips rounded to the next integer.

Capacities may reflect any limitation on trucks and multiple

resources may be defined. Each will receive a column for

data on the plan. There is a penalty for violating the capacity

constraint. The penalty is charged for each unit of capacity

in excess of the amount available. The capacity constraint

for the example, will assure an equal number of delivery

sites for each truck if the penalty is set high enough. |

| Customer Location |

This is the index of the table on the customer worksheet

that identifies the location of the truck or delivery. |

| Customer Location Name |

The names are transferred from the customer worksheet. |

| Customer Geometric or Cartesian Coordinates |

There are two columns that express the coordinates of the

customer locations specified as latitude and longitude for

geometric coordinates and x and y for Cartesian coordinates.

The cells are yellow because formulas in these columns link

to the map location information on the customer worksheet. |

| Map Location |

This is the index of the table on the distance worksheet

that identifies the map location of the truck or delivery.

The map location is assigned as the closest map location

to the delivery site or truck depot. |

| Map Location Name |

The names are transferred from the distance worksheet. |

Map Geometric or Cartesian Coordinates |

There are two columns that express the coordinates of the

customer locations specified as latitude and longitude for

geometric coordinates and x and y for Cartesian coordinates.

The cells are yellow because formulas in these columns link

to the map location information on the customer worksheet. |

| Local Distance |

This is the Euclidean distance between the assigned map

coordinates and the truck or delivery site coordinates. When

travel takes place from one site to another, the trip is

assumed to be the map distance between the two sites plus

the sum of the two local distances. Both local distance and

the distance between map locations are assessed costs that

are proportional to the cost per unit time and travel time

per unit distance. |

|

| |

The Results worksheet for

the example is below. This worksheet shows a solution to the

TSP. The solution is given in column E as the sequence of truck

and

delivery

map locations that will be followed by the single truck. The

solution process starts with an initial sequence that starts

at the truck origin location, visits the delivery sites in numerical

order and finishes at the truck terminal location. The solution

is modified by various heuristics until a local optimum solution

is obtained. That solution is reported below. All the examples

on this page follow the same process, so the results are comparable. |

|

VRP Considering only Distance |

| |

The second example uses two trucks

for the deliveries. We call this the vehicle routing

problem (VRP). Each truck has the

resource capacities of

5, so the solution should have two tours of five deliveries.

The only change in the dialog from the TSP example is the number

of trucks. |

| |

|

| |

Each truck has two rows and each

delivery has one. For this example we assign the trucks to two

different locations, L-9 and L-14. |

|

| |

The results after improvement show

two routes,

one for each truck. The total cost, about 205, is larger than

the cost for the TSP, about 136. |

|

VRP Considering Distance and Time |

| |

Click the Include Time button on

the dialog for the new model. |

|

| |

The planning data worksheet for

this case is shown below. Columns are added to hold the time

data for the trucks and deliveries. Also new parameters transform

distances to times. |

|

| |

The table defines the columns

holding the time data.

| Depot Time or Delivery Time |

This is the fixed time to load a truck or make a delivery.

The time that a truck leaves the site is the arrival time

plus the delivery (depot) time. |

| Ready Time |

This is the earliest time that a particular truck may

start or that a particular site will accept a delivery.

This is a hard constraint. If a truck reaches a site before

the ready time, it must wait to begin the delivery process.

For the origin node of a truck, the time will indicate

the time the truck begins its route. |

| Early Time |

This is a scheduled earliest time for a truck to arrive

at a delivery site. The truck may arrive before this time,

but a penalty will be assessed. The early time differs

from the ready time in that the early time constraint may

be violated, but at a penalty, while the ready time constraint

is never violated by a solution. |

| Late Time |

This is a scheduled latest time for a truck to leave

a delivery site. The truck may leave after this time, but

a penalty will be assessed. A truck leaves a site at the

arrival time plus the delivery (or depot) time. For the

terminal site of a truck, this might be the end of the

working day. |

| Duration Penalty |

When a truck leaves a site, the solution is assessed

a cost that is the duration penalty multiplied by the leaving

time. This parameter can reflect priorities with sites

having greater duration penalties having higher priorities. |

|

| |

The solution to the example is

below. For this model the cost model depends on time. The travel

cost component

is the total distance divided by the velocity and multiplied

by the cost

per minute. The solution mirrors the dual effects of distance

and duration penalties. |

|

VRP Considering Distance, Time and Time Windows |

| |

Time windows express customer requirements

for early and late delivery. For the time window feature

click the Include Time Windows checkbox. |

|

| |

The data worksheet with time windows

is below. |

|

| |

New columns in the data determine

the time windows and the penalties for violating the time windows.

| Early Time |

This is a scheduled earliest time for a truck to arrive

at a delivery site. The truck may arrive before this time,

but a penalty will be assessed. The early time differs

from the ready time in that the early time constraint may

be violated, but at a penalty, while the ready time constraint

is never violated by a solution. |

| Late Time |

This is a scheduled latest time for a truck to leave

a delivery site. The truck may leave after this time, but

a penalty will be assessed. A truck leaves a site at the

arrival time plus the delivery (or depot) time. For the

terminal site of a truck, this might be the end of the

working day. |

| Early Penalty |

When a truck arrives at a site before the early time,

the solution is assessed a cost that is the early penalty

multiplied by the difference between the early time and

the arrival time. When a truck arrives after the early

time, no early penalty is charged. |

| Late Penalty |

When a truck leaves a site after the late time, the solution

is assessed a cost that is the late penalty multiplied

by the difference between the leaving time and the late

time. When a truck leaves before the late time, no late

penalty is charged. |

For simplicity we have made the duration penalties 0 for this

example. |

| |

The solution for this model tries

to meet the time windows. For the example this is impossible.

D-8 is visited early (Column S) and several deliveries are late (Column

T). Time windows for trucks model the desired leaving and returning

tins for the trucks. Both trucks return to their depots late. |

|

Nonzero Local Distances. |

| |

Nonzero local distances occur

when the locations on the distance worksheet are different

than the distances on the customer worksheet. The example uses

the data below.

|

| |

The example uses the data from

the previous examples, but specifies different customer and

map locations. The local distances are computed in column W.

| Local Distance |

With Cartesian coordinates this column holds the Euclidean

distances between the assigned map coordinates and the

truck or delivery site coordinates. For geometric coordinates,

the Great Circle distance is the metric. When travel takes

place from one site to another, the trip is assumed to

be the map distance between the two sites plus the sum

of the two local distances. Both local distance and the

distance between map locations are assessed costs that

are proportional to the cost per unit time and travel time

per unit distance. |

|

|

| |

When time is not included in the

model, such as the TSP in the first example, nonzero local distances

do not matter. When time is included, the local times are added

to the map travel times to find the total travel times between

two sites. This increases the time consumed by all parts of the

routes. Greater

total duration costs and time window costs are to be expected. |

|

Maps |

| |

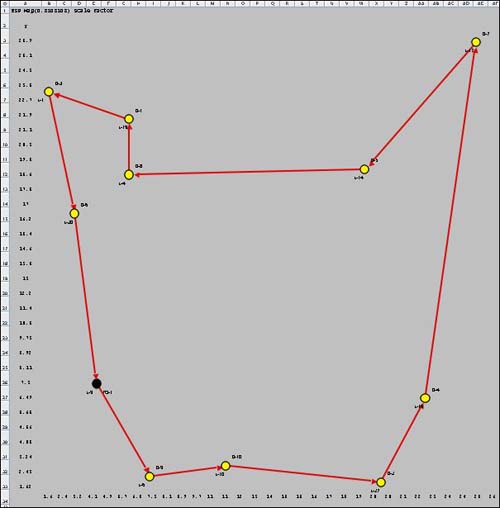

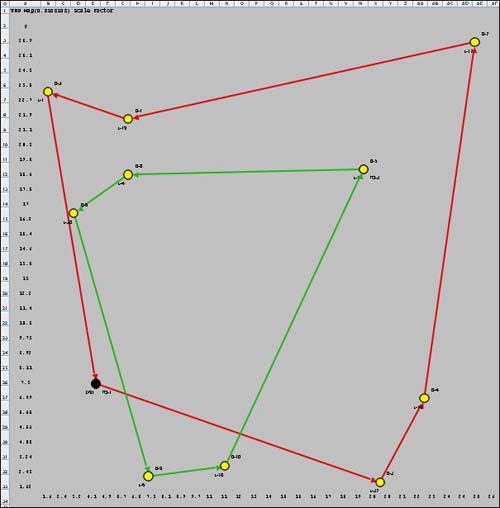

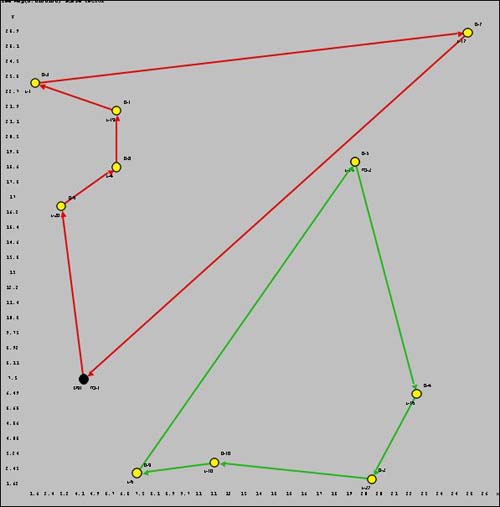

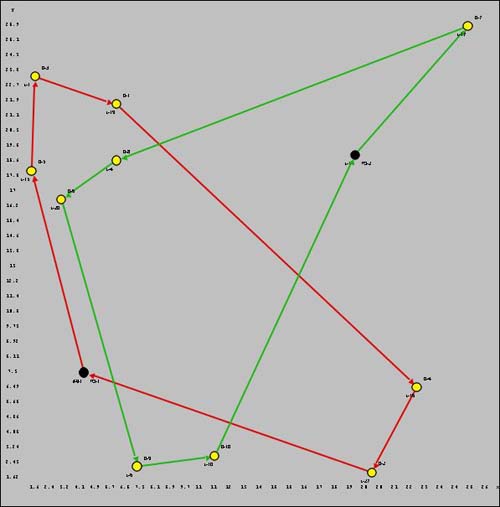

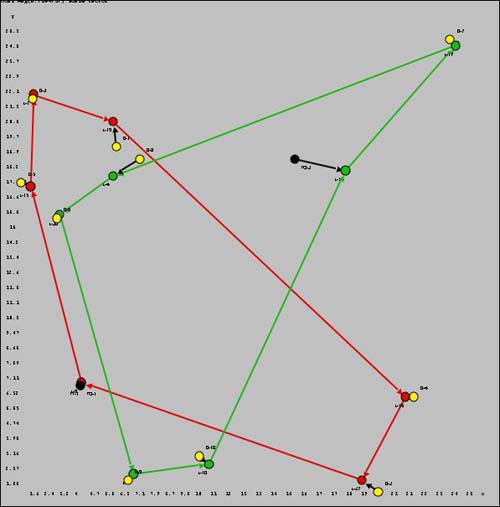

It is interesting to compare the

maps of the five cases considered above. The TSP has a single

route

where all others have two. Yellow dots show delivery locations

and black dots show truck locations. In the green route

for the VRP map, one of the deliveries has the same location

as the truck. The yellow dots take preference. |

TSP Map

|

VRP Map

|

VRP with Time

|

VRP with Time and Windows

|

VRP with nonzero Local Distances

|

For the last example, local distances are nonzero. The

local distances are shown with black lines outside the routes.

The black and yellow dots are not directly on the routes

but connect to red or green dots on the route. The red and

green dots are map locations. |

|

| |

We provide these examples to illustrate

the options available for problem definition. We return to these

examples to discuss solution procedures. |

| |

|