|

|

|

Vehicle

Routing |

|

-

Planning Data |

|

|

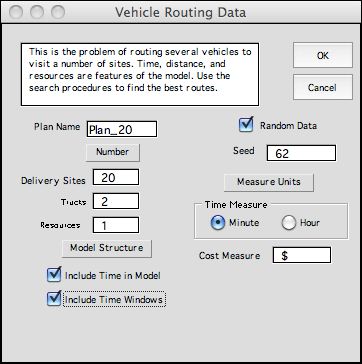

The Planning Data worksheet

holds data specific to a particular routing problem. Clicking

the Make Plan button at the top of the Distance worksheet

for the Austin example creates the worksheet. The Vehicle

Routing Data dialog

accepts data for a plan. A Distance worksheet may

have several plans, but each Planning Data worksheet

is based on a specific Distance worksheet.

A plan has a name that is used to name the worksheet created

at this step. Many named ranges on the worksheet also use the

name. The name may contain only alphanumeric characters with

no spaces or punctuation. It cannot be changed once the worksheet

is created. Do not change the name on the worksheet tab. Three

numeric fields define a plan: the number of deliveries, the

number of trucks, and the number of resources. The Random

Data checkbox causes the add-in to insert random data

into some of the data fields. The Seed controls the

random number stream. The time measure is specified as hours

or minutes. The cost measure is the field on the lower right.

Here is the symbol for U.S. dollars ($).

The dialog accepts the number of deliveries to be made and

the number of individual vehicles (called trucks)

used to make the deliveries. A truck begins its route at

some starting point, visits a collection of delivery sites,

and completes its route at a finish point. The start

and finish points are usually at the same place for a given

truck, but the data can specify different places. Different

trucks will serve their routes simultaneously.

Deliveries use truck resources such as space or weight.

Our example uses a single resource called capacity. Each

delivery requires one unit of capacity (capacity utilized is

called load) and the default value of the truck

capacity is the number of deliveries divided by the number

of trucks rounded up to the nearest integer. For example, two

trucks making 20 deliveries will each have a capacity of 10.

A constraint of this kind partitions the deliveries into trips

with a different truck for each trip. |

Example |

| |

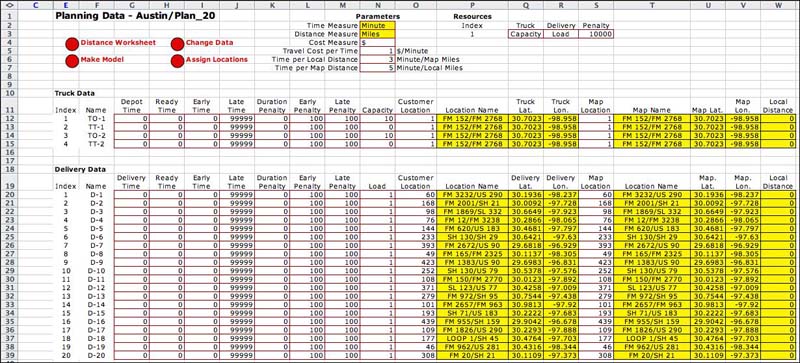

An example plan is shown below. We

discuss the various data items below the figure. Click the picture

to open a window with a larger image. |

|

| |

The data has three parts: the

parameters at the top, the truck data starting in

row 11, and the delivery data staring in row 19. The parameters

in column N define three constants related to time, distance

and cost in N2, N3 and N4. The next entry, N5, requires an

estimate of cost per unit of travel time. The principal mode

of travel for vehicles is on the routes between map locations,

however, truck depots and delivery sites may be located at

geographic locations not on the map. Travel between two

sites on a route has three parts, travel from the local location

of the first site to a nearby map location, travel from one

map location to a another, and finally travel to the local

location for the truck. Entries in cells N6 and N7 specify

the travel time per unit distance for local and map travel.

For the example, we assume the cost measure is dollars

and the time measure is minutes, so the example shows $1

per minute in N5. The entry in N6 is the time required for

distances traveled between locations on the Distance worksheet.

If we measure time in minutes, the example specifies 3 minutes

per mile (20 miles an hour) for travel between map locations.

N7 shows the time required for each unit of distance traveled

from a map location to the site of a delivery. We call this

the local distance. The example shows 5 minutes per mile or

12 miles an hour. This assumes travel between locations defined

by the Distance worksheet

is faster than local travel.

The resource data starting in column Q gives the names for

the resources when applied to trucks, Q3, the names for deliveries,

R3, and the penalties for using more resource than is available,

S3. When a single resource is specified, the default names

are capacity and load.

The penalty value, 1000, for the example, is used by the

optimization to penalize violations of the resource constraint.

One might increase or decrease this number depending on the

flexibility of the resource.

The truck and delivery data have similar columns. All the

data in these columns may be set by the user except the yellow

fields. The customer location column is column O. These entries

are the indices from the customer worksheet. For the example

we assign the start and finish locations for the trucks as

customer location 1. If we look on the customer worksheet we

find this site has the name FM 152/FM 2023, indicating the

intersection of two farm roads. The geographic coordinates

of this location are transferred from the customer worksheet

by formulas using the entry in column O as the index. In a

similar fashion the locations of the deliveries are specified

by indices to entries on the customer worksheet. For the example,

these numbers were assigned randomly. For an actual case they

would be determined by the delivery schedule for the day.

The entries in column S are indices of the table on the distance

worksheet. These define the name, latitude and longitude to

the map location assigned to the truck or delivery. We assign

a map location to as close as possible to the customer location.

For the Austin example, the customer list is the same as the

map table, so the map location assignment is the same as the

customer location. In general, customer locations will not

be the same as map locations. To find the closest map points

to the customer locations click the Assign Locations button

at the top of the worksheet. This button evaluates sequentially

assigns each customer location to the test point cells

on the distance worksheet. The minimum distance point in column

K of the customer worksheet is placed in column S.

The distance between a customer location and the assigned

map location is called the Local

Distance.

This field is computed with Excel formulas. Since the customer

and map worksheets are the same for the example, the local

distances are all zero. |

| |

The several columns of the plan

worksheet are listed below. To keep the example simple, the

example uses the default values of the parameters except the

location indices.

| Name |

The default names are assigned as in the example,

but can be changed to identify specific vehicles and delivery

points. Two entries are required for each truck representing

its starting location, TO-1, and its terminal location, TT-1. The

letter O stands for origin, and the letter T stands

for terminal. Each truck occupies two rows of the

table, even numbered rows are out-going and odd numbered

rows and in-coming. |

| Depot Time or Delivery Time |

This is the fixed time to load a truck or make a delivery.

The time that a truck leaves the site is the arrival time

plus the delivery (depot) time. |

| Ready Time |

This is the earliest time that a particular truck may start

or that a particular site will accept a delivery. This is

a hard constraint. If a truck reaches a site before the ready

time, it must wait to begin the delivery process. For the

origin node of a truck, the time will indicate the time

the truck begins its route. |

| Early Time |

This is a scheduled earliest time for a truck to arrive

at a delivery site. The truck may arrive before this time,

but a penalty will be assessed. The early time differs from

the ready time in that the early time constraint may be violated,

but at a penalty, while the ready time constraint is never

violated by a solution. |

| Late Time |

This is a scheduled latest time for a truck to leave a

delivery site. The truck may leave after this time, but a

penalty will be assessed. A truck leaves a site at the arrival

time plus the delivery (or depot) time. For the terminal

site of a truck, this might be the end of the working day. |

| Duration Penalty |

When a truck leaves a site, the solution is assessed a

cost that is the duration penalty multiplied by the leaving

time. This parameter can reflect priorities with sites having

greater duration penalties having higher priorities. |

| Early Penalty |

When a truck arrives at a site before the early time, the

solution is assessed a cost that is the early penalty

multiplied by the difference between the early time and the

arrival time. When a truck arrives after the early time,

no early penalty is charged. |

| Late Penalty |

When a truck leaves a site after the late time, the

solution is assessed a cost that is the late penalty multiplied

by the difference between the leaving time and the late

time. When a truck leaves before the late time, no late penalty

is charged. |

| Capacity/Load |

The first resource constraint is automatically named the

capacity. The loads associated with the delivery sites use

the capacity of a truck. The default load for each site is

1 and the default capacity of each truck is the total load

divided by the number of trips rounded to the next integer.

Capacities may reflect any limitation on trucks

and multiple resources may be defined. Each will receive

a column for data on the plan. There is a penalty for violating

the capacity constraint. The penalty is charged for each

unit of capacity in excess of the amount available. The capacity

constraint for the example, will assure an equal number

of delivery sites for each truck if the penalty is set high

enough. |

| Customer Location |

This is the index of the table on the customer worksheet

that identifies the location of the truck or delivery. |

| Customer Location Name |

The names are transferred from the customer worksheet. |

| Customer Geometric or Cartesian Coordinates |

There are two columns that express the coordinates

of the customer locations specified as latitude and longitude

for geometric coordinates and x and y for Cartesian coordinates.

The cells are yellow because formulas in these columns link

to the map location information on the customer worksheet. |

| Map Location |

This is the index of the table on the distance worksheet

that identifies the map location of the truck or delivery.

The map location is assigned as the closest map location

to the delivery site or truck depot. |

| Map Location Name |

The names are transferred from the distance worksheet. |

Map Geometric or Cartesian Coordinates |

There are two columns that express the coordinates of the

customer locations specified as latitude and longitude for

geometric coordinates and x and y for Cartesian coordinates.

The cells are yellow because formulas in these columns link

to the map location information on the customer worksheet. |

| Local Distance |

This is the Euclidean distance between the assigned map

coordinates and the truck or delivery site coordinates. When

travel takes place from one site to another, the trip is

assumed to be the map distance between the

two sites plus the sum of the two local distances. Both local

distance and the distance between map locations are assessed

costs that are proportional to the cost per unit time and

travel time per unit distance. |

|

| |

The information entered on the Data worksheet

defines the set of the deliveries required for some interval

of time, perhaps a day of operation. The add-in tries to develop

a schedule that will meet the delivery requirements with the

trucks provided. The criterion is a composite cost

that includes the cost for travel, the total duration penalties,

the total early and late penalties, and the total resource violation

penalties. The model involves both time and distance as will

be reflected on the model worksheet.

We have entered sample data to the data worksheet. It represents

a problem with two trucks and twenty deliveries. Default values

are used for the time aspects of the problem. |

Alternative Data Forms |

| |

|

Although the example has columns for

time parameters, they did not effect to the solution.

The time delays for loading and unloading trucks are

all set to zero, so the time features of the model are

not effective. Options on the data dialog allow models

to exclude time and exclude time windows. The dialog

shows how to make a model that does not include

time. The checkbox for Include

Time in Model is simply left unchecked.

The planning data worksheet shown below is simplified

with the columns holding time data left out. The results

and model worksheets are similarly simplified. Note that

the cost only depends on the travel cost per mile. When

time is included the objective is to minimize the total

cost depends on the travel distance through the time

per travel mile and the cost per travel time parameters. |

|

|

| |

The map of the solution of the model

with no time features is below. This solution has the goal of

minimizing total distance where the two routes divide the deliveries.

The solution may not be optimum because heuristic solution methods

are used. |

|

| |

|

If the model is to represent time

but not time windows, leave the Include Time Windows box

unchecked. The plan in This case is shown below. We have

entered nonzero parameters for depot and site times. The

solution depends on the finish

time for each customer. On the data form we provide nonzero

penalties for the ten customers with the greatest indices. |

|

|

| |

The solution map shows the effect

of penalties. The solution has all the sites with nonzero penalties

visited first. |

| |

|

Changes |

| |

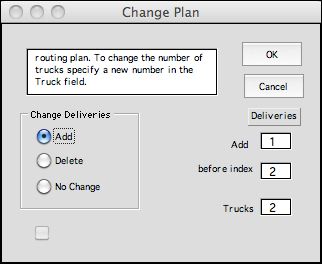

Once constructed, the number of

deliveries and the number of trucks

may be changed using the Change button.

The dialog below specifies the number of deliveries to be added

or deleted and the location of the change. To change the number

of trucks, specify a new value in the associated field. The

example adds a new delivery to the plan and places it above

the delivery that is currently second. The deliveries will

be re-indexed after the addition. New deliveries can't be added

before index 1. The last delivery cannot be deleted.

|

Buttons |

| |

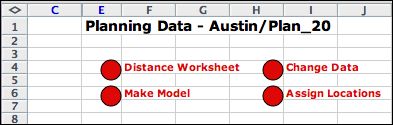

At the top of the page there are

several buttons.

The Distance Worksheet button makes

the distance worksheet active. Each plan has a unique associated

distance worksheet. The Change Data button allows

changes in the plan. All features of the model can be changed

except the number of resources. The Assign Locations button

determines the closest map location to each delivery or depot

location. This is useful when the plan is given coordinates

for each truck and delivery site that are different than the

map locations. The Make Model button constructs the model and results worksheets

discussed on the following pages.

Data on the model worksheet are

directly linked to the contents of the planning data worksheet.

There is no need to create a new model when the data is changed,

however, if the numbers of trucks or deliveries change, a new

model is required. |

| |

|

|