|

|

|

Vehicle

Routing |

|

-

Results |

|

|

The Make Plan button

at the top of the Data worksheet creates two worksheets,

the Model worksheet and the Results worksheet.

The Model worksheet implements our model of the vehicle

routing problem. It is used by the Optimize Sequence add-in

to evaluate and improve solutions. The Results worksheet

reports the results of the solution algorithms. For the casual

user, it is not really necessary to learn all the details of

the model worksheet, so we present the results worksheet first.

Most of the figures on this page are reduced for presentation.

A larger version shows when the picture is clicked. |

Results Worksheet |

| |

The figure below shows the results worksheet

as it first appears and before any attempt to find a good solution.

Click the figure to open a window with a larger illustration.

The solution is described by the sequence shown in column E.

The origin and terminal truck sites and the delivery sites

are each assigned a unique index with the trucks numbered first

and then the delivery sites. For the example, the first truck's

origin and terminal sites are numbered 1 and 2. The second

truck has sites numbered 3 and 4. The twenty deliveries are

indexed 5 through 24. The initial sequence is in index order

with one exception. The first three truck sites are first in

the sequence, followed by the delivery sites, and finally site

4, the terminal site of the last truck. This means that the

initial solution has all the deliveries assigned to the last

truck. Although this is not often a good solution, it is used

as a starting solution for the heuristic search methods to

be described later.

The Sequence column is shown in green to indicate

that the user may change the sequence. When one of the search

routines in invoked, the add-in fills this column with the

solution obtained. |

|

| |

Some of the columns of this form are taken

from the data worksheet and others are transferred from the

model worksheet. We list below the meanings of the

various columns. The contents of the columns are controlled

by the add-in so any user changes, except in the sequence column,

are neglected. The yellow cells at the top of the page hold

Excel formulas that hold the various cost components as computed

on the model worksheet. Our goal is to find a sequence that

minimizes the Total

Cost computed

in cell L7.

Red lines on the table indicate the start and finish of truck

routes.

For the initial solution the first truck begins at time 0,

visits no delivery sites, and immediate returns to its finish

site. The second truck then handles all the remaining deliveries.

Of course this not a good solution, but it will serve to illustrate

the columns of the form. |

| |

| Column C |

This is the untitled column C on the figure.

The column identifies where each truck begins its trip. |

| Column D |

This column is also untitled. It holds the indices of

the display |

| Sequence (E) |

The sequence is given by the indices assigned to the truck

and delivery sites. The initial sequence is in column E.

The solution sequence determined by the add-in will

be placed here. |

| Name (F) |

The names are assigned on the plan-data worksheet. |

| Location (G) |

The map locations are assigned on the plan-data worksheet. |

| Location Name (H) |

The map location names associated with the locations of

the truck and delivery sites. |

| Type (I) |

T indicates a truck origin and its terminal site

is R. Deliveries have the type D. |

| Trip (J) |

Trips are numbered sequentially. Truck 1 is always assigned

trip 1, but the trip numbers of other trucks and deliveries

depend on the sequence. |

| Time Available (K) |

This is assigned on the plan-data sheet. The default value

is 0. |

| Early Time (L) |

This is assigned on the plan-data sheet. The default value

is 0. |

| Arrive (M) |

This is the arrival time at a site. The arrival time is

computed considering the distances between adjacent sites

on the route, the delivery times and the available times.

Trucks run routes independently. A truck begins its trip

at the truck's available time, 0 for the example. The arrival

times for subsequent deliveries are determined on the model

worksheet. |

| Site Time (N) |

These times are defined on the plan-data sheet. |

| Late Time (O) |

This is assigned on the plan-data sheet. The default value

is 9999. |

| Depart (P) |

A truck departs from the site at the arrival time plus

the site time. The departure times are multiplied by the

duration penalties to compute the cost component of L3. |

| Local Travel Time (Q) |

After a truck departs a site, it must travel to the assigned

map location. The time for this trip is in this column. |

| Travel Time to Next Site (R) |

On leaving the customer location the truck travels the

local distance to the map point nearest the customer location.

The truck then travels to the map location of the next site

in the sequence. It then travels for the local time to reach

next customer location. Each of these distances are divided

by the velocity of the truck. This column shows the total

of these three times. |

| Early (S) |

This is the amount of violation of the early time constraint. |

| Late (T) |

This is the amount of violation of the late time constraint. |

| Cumulative Capacity (U) |

Each truck contributes to capacity and each delivery

takes capacity away. The cumulative capacity computes the

amount of capacity remaining at any point in the sequence.

For the example, each truck has capacity for ten deliveries.

In the initial solution the first truck makes no deliveries,

so its capacity is essentially wasted. The second truck makes

all 20 deliveries. Column U shows that after the tenth

delivery the cumulative capacity becomes negative. This indicates

a shortage in capacity for the second truck. |

| Capacity Short (V) |

This column reports a positive value equal to the cumulative

capacity when the later number is negative. This indicates

how much the resource constraint is violated. The total short

is multiplied by the resource violation penalty to compute

the cost component in L6. |

|

| |

The information entered on the Planning

Data worksheet

defines the set of the deliveries required for some interval

of time, perhaps a day of operation. The add-in tries to develop

a schedule that will meet the delivery requirements with the

trucks provided. The criterion is a composite cost

that includes the cost for travel, the total duration penalties,

the total early and late penalties, and the total resource violation

penalties. The model involves both time and distance as will

be reflected on the model worksheet. The results worksheet is

not dynamic. Changing the information in some cells does not

automatically reflect in the values of other cells. |

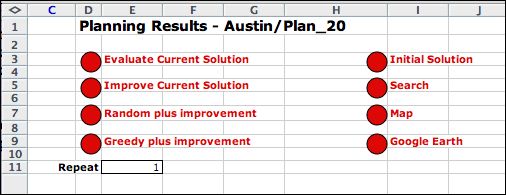

Buttons |

| |

At the top of the page there are

several buttons. The first button on the left evaluates the

current solution. If the sequence is changed in column E, click

this button to see the results of the change. The second button, Improve

Current Solution, uses insert, switch and turn heuristics

to improve the solution. The third button, Random plus

improvement option generates a random solution and improves

it to a local minimum. The Greedy plus improvement option

generates a greedy solution and improves it to a local minimum.

The first button on the right creates the feasible initial

solution. The Search button opens a dialog that allows

the specification of more complicated search options. The Map button

creates a worksheet with a map of the current solution. The Google

Earth button

creates a program the is used to show the solution on the Google

Earth application. This button only appears when locations

are given geometric coordinates.

The cell E11 allows the heuristic to be run several times

in succession. It is only effective for one of the improvement

options that involve random starts. For example if the repeat

number is set to 10 and we choose the Random plus Improvement option,

the improvement process is carried out ten times. If more than

one local optimum is reached. The solution found is the best

of these.

To illustrate the improvement process we choose

the Random plus Improvement button. The results are

shown below. Click the figure to see a larger illustration. The

first truck visits delivery sites 14, 13, 12, 16, 9, 7, 20, 17, 1, and 8. The

second truck visits sites 3, 6, 10, 18, 5, 15, 2, 11, 4, and 19. There is no

shortage in the capacity, since each truck makes 10 deliveries. The

sequence of trucks and deliveries defines the two trips. There may be better

solutions than this one since a heuristic solution cannot guarantee

the optimum. |

|

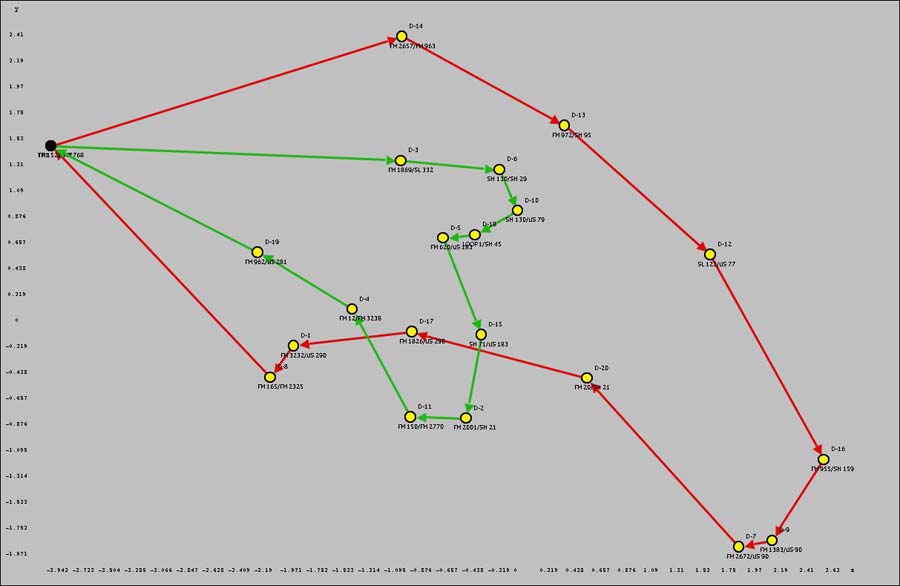

Map |

| |

Clicking the Map button creates a map

showing the two trips. Trips routes between map locations are

colored green and red. Delivery

locations are yellow and truck locations

are black. |

|

| |

There is no guarantee that this

is an optimum solution. The multiple vehicle routing

problem is a hard problem. There are optimization models that

can assure optimality, however, large problems may lead to

prohibitive computation times even on powerful computers.

On a later page we show examples of this problem with other

parameters, but the next page considers the model worksheet. |

| |

|

|