|

|

|

Vehicle

Routing |

|

-

Model |

|

|

The Model worksheet is

entirely constructed by the Routing add-in. Its purpose

is to collect data from the Data worksheet,

interact with the search algorithms in the Optimize

Sequence add-in, and report solutions on the Results worksheet.

Although users familiar with the add-ins

may experiment by changing some features of this worksheet,

in general it is better to leave it alone.

In the following we divide the model worksheet into three

parts to simplify the discussion. The parts are different in

function. The particular

solution shown in the example is the same one illustrated on

the Results page. |

Optimize Model |

| |

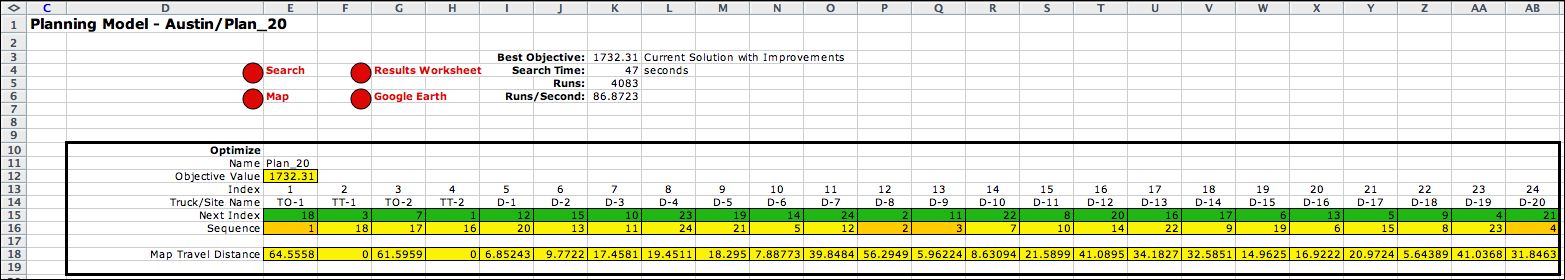

At the top of the model worksheet

shown below are the control buttons and the results of the

most recent computation. Rows 10 through 19 hold the decision

variables, the objective function, the current sequence and

the distances between map locations. A similar form is constructed

by the Optimize add-in

as described on the Combinatorial

Form page. The form is particularly adapted to the TSP on

the Traveling

Salesman page. Here we adapt the TSP form for

the routing problem.

For this model we identify the items to be sequenced as nodes.

Each node is related to a truck origin node, a truck

terminal node or a delivery site. The nodes referring to trucks

are indexed first. For example with two trucks, the first four

nodes are TO-1, TT-1, TO-2, and TT-2. The last ten nodes relate

to delivery sites, nodes 5, 6, ... 14 refer respectively to

D-1, D-2, ... D-10. This one-to-one assignment does not change

during the solution process. The relationships between nodes

and the routing problem elements are stored on the Excel worksheet

in rows 13 and 14.

We seek the sequence of nodes that gives the smallest value

to the objective function in cell E12. E12 holds a formula

that evaluates the complex cost model described on the remainder

of this page.

There are some rules concerning acceptable

sequences. The first rule is that the first node of the sequence

represents the origin node of the first truck. For the example,

node 1 representing TO-1 must begin the sequence. The second

rule is that the last node of the sequence must represent the

terminal node of the last truck. For the example, node 4, representing

TT-2, must end the sequence. Further wherever a truck terminal

node appears in the sequence, the origin node of the next truck

must follow. We see this in the figure where the terminal node

for truck 1 appears as the 7th node in the sequence. The origin

node of truck 2 must be the 8th node of the sequence.

This assures that every delivery is handled by exactly one

truck. The enumeration

process maintains these relationships.

Row 15 describes the sequence by indicating for each node

the next node in the sequence. We see in E15 that node 13 (D-9)

follows node 1 (TO-1). In Q15 we see that node 9 (D-5) follows

node 13 (D-9). This process can be continued to find the complete

sequence. The entries in row 15 are the variables of the problem.

They are controlled by the program that implements the heuristic

solution process.

Row 16 describes the sequence more directly by listing the

nodes in sequence order. E16 holds the first node in the sequence,

node 1 (TO-1). F16 holds the second node in the sequence, node

13 (D-9). G16 holds the third node in the sequence, node

9 (D-5). The process continues until the last node in the sequence

is reached. This is node 4 representing the terminal node of

the second truck,

TT-2. Row 16 is computed with Excel formulas

from decisions in row 15.

Row 18 holds the map distances between the locations of adjacent

nodes in the sequence. For instance the value of E18 is the

distance between the location of node 1 and the location of

node 13. For the example, the location of node 1 is L-9, and

the location of node 13 is L-6. E18 is the distance between

L-9 and L-6. The numbers in row 18 are Excel lookup functions

that reference a matrix further down on this models page. |

|

| |

For

the example, the sequence is (1,

13, 9, 8, 6, 14, 2, 3,

11, 5, 7, 10, 12, 4).

The colored indices in the sequence are nodes related to

the trucks. The particular sequence defines the route (1,

13, 9, 8, 6, 14, 2)

for truck 1. The route begins at the origin location of truck

1 and ends at the terminal location of truck 1. The route for

truck 2 is (3,

11, 5, 7, 10, 12, 4).

It begins at the origin location of truck 2 and ends at the

terminal location of truck 2. The travel distances associated

with the links of the trip are selected from the distance matrix

using a LOOKUP equation. For example, the value, 8.83899,

in cell E18 is the Euclidean, or straight-line distance, from

node 1 to node 13. The other entries in row 18 are

similarly computed. |

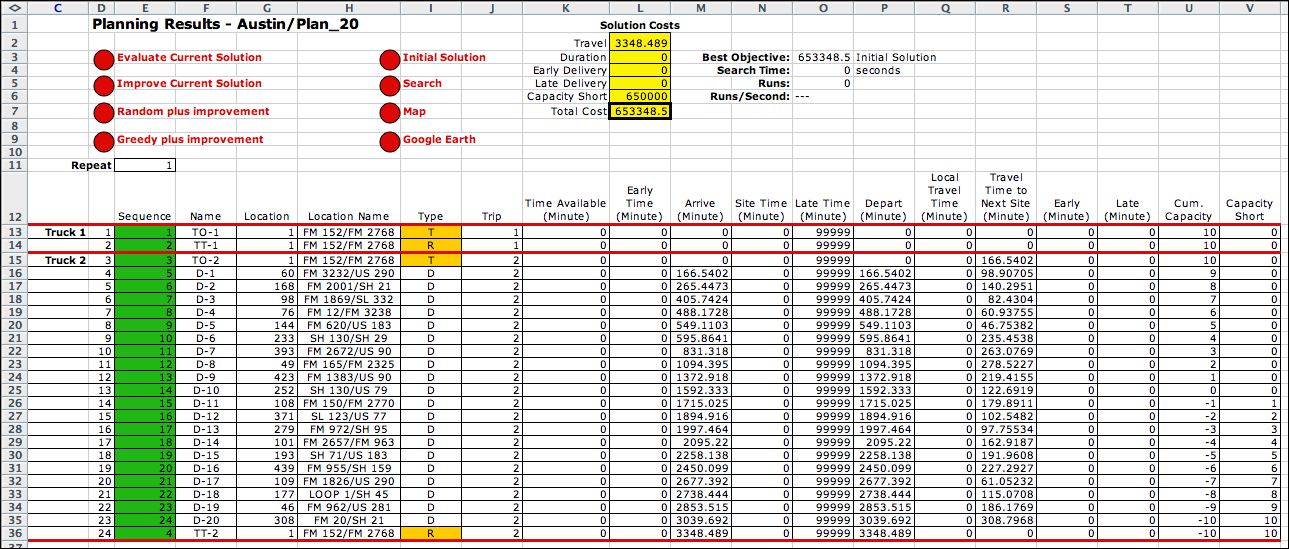

Data Cells |

| |

The sequence of trucks and delivery nodes is described

in row 42. Most of the rows on this form have similarly

named columns on the Data worksheet. The rows 28,

29 and 34 hold parameters related to distance that are provided

by single entries at the top of the data worksheet. The data

cells shown below do not depend on the current sequence. They

are colored yellow to indicate that the cells hold formulas

that link to the data worksheet and remain fixed throughout

the solution process. |

|

Results Cells |

| |

The results cells starting in row 41 are controlled

by the current sequence. All the cells are colored

yellow to indicate that they contain Excel formulas. The columns

are ordered by the current sequence. The display is dynamic in

that the columns change as the decision variables in row 16

change. For each trial solution, the objective value is computed

from this portion of the worksheet.

The sequence of trucks and delivery

nodes is in row 42. Row 43 identifies the type of the node,

T for origin truck nodes, R for truck terminal nodes, and D

for delivery destinations. The trip row (44) gives an integer

index that indicates the components of the sequence that are

assigned to the various trips. The current example has two

trips representing the routes of the two trucks. The times

available, early times, site times, late times, and local travel

times are transferred by index functions from the data cells.

An arrival time in row 47 is computed as the sum of departure

time of the previous node plus the travel time to the next

node. If this turns out to be earlier than the time available,

the time available becomes the arrival time. The departure

time in row 50 is computed as the arrival time plus the site

time. The travel time to the next node in row 52 is the sum

of: the local travel time from the current node to its map

location, the map travel time between the current node and

the next node, and the local time to the next node.

Row 46 shows the arrival time at each node and row 50 shows

the corresponding departure time. Notice that starting at truck

1, the times increase through the route of truck 1 until the

terminal node for truck 1 is encountered. The

terminal node for truck 1 is immediately followed by the origin

node for truck 2. The arrival time for truck 2 is 480. This

is the beginning of the second trip. The second trip occurs

simultaneously with the first trip. The second trip is completed

by the terminal node for truck 2. |

|

| |

The evaluation of the sequence in terms of

the early and late times and the resource shortages begins

on row 54. Row 55 shows the deliveries that are early, D-4

and D-6. Row 56 shows the deliveries

that are late, D-1 and D-3. Row 57 shows the cumulative capacity

for the sequence. When a new truck is assigned to a trip,

the cumulative capacity for the trip is the capacity of that

truck. As the truck visits delivery nodes, the loads of the

delivery sites decrease the cumulative capacity. A negative

number in this row indicates a shortage. Row 58 reports the

amounts of the shortages. Since the current sequence has no

shortage, the contents of this row are 0.

Rows 61 through 65 numerically evaluate the solution. Row

61 shows the travel costs. The duration costs in row 62 are

computed by multiplying the departure times by the duration

penalties. The example uses 0 as the duration penalties, so

the entries are all 0. The early and late costs multiply

the sum of the early and late amounts by the penalties

for these factors. The contributions of each node to the objective

function are computed in row 66.

All the costs and penalties are accumulated in column T that

is not shown in the figure. The total amount is transferred

to the objective function cell E12 at the top of the worksheet. |

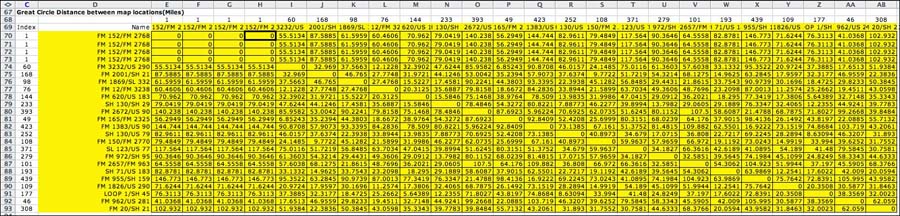

Distance Matrix |

| |

Starting in row 67 is a square matrix holding

the distances between the map locations in the plan. This matrix

addresses data on the distance worksheet. When a table provides

intersite distances and the distance page, the entries to the

matrix on the model page are simple lookup functions addressing

the distance matrix. When the locations are described by the

Cartesian coordinates, the

entries in the model matrix are equations computing the Euclidean

matrix (Pythagorean theorem). When the locations are described

by the geometric coordinates, the

entries in the model matrix are equations computing the Great

Circle distance.

In all cases the matrix does not change with the solution,

so the computation time associated with building the matrix

is experienced only when the matrix is created by the add-in.

This speeds up computation during the solution process. |

|

Location Coordinates |

| |

Row 94 begins a series of rows that compute the

coordinates of the map points in the solution. Geometric coordinates

are used for the map construction of Google Earth. Euclidean

coordinates are used for the Map graphics created by the add-in. |

|

Sequence Optimization |

| |

The Optimize Sequence add-in is used to search

for the optimum sequence. To illustrate the solution process,

we will use the initial solution shown below. The initial

solution is created by clicking the Initial Solution button

on the Results worksheet. The solution is feasible, but it

assigns all the deliveries to the last truck. We will use search

heuristics to find a better solution.

Because it uses heuristic procedures there is no guarantee

that the search will obtain the optimum solution unless all

possible sequences are examined. The algorithm incorporates

several search heuristics that are designed for general sequence

problems but adapted for the routing problem. The process manipulates

the variables in the green cells of row 15 and observes the

resultant objective function in cell E12. |

|

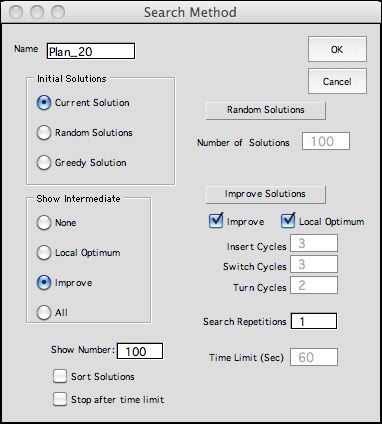

| |

To improve the current solution, click the

Search button at the top of the worksheet. The dialog below

is presented. Click the Improve checkbox at the right

side of the dialog. Also check the local optimum box.

The Improve button on the left of the dialog indicates

that you want to review all the improved solutions encountered

by the process.

|

| |

As the search progresses, each solution is placed on the worksheet

and the solution is evaluated by the Excel worksheet functions.

The results of the evaluations are used to direct the search

process.

If the Show Improve button is clicked, the

search process maintains a list of improving solutions. The

figure below shows the results of the search leading to the

example solution. The cells involving truck nodes are highlighted.

These displays are on the Results worksheet. Note

that the objective value at the first run is the initial solution,

subsequent runs have decreasing objective values. The bottom

row is the result of run 2988. It is a local optimum solution

and cannot be improved. |

|

| |

To the right of the next-index solutions,

the associated sequences are also listed. The first few insert

moves divides the deliveries among the two trucks, and the remaining

steps interchange pairs of nodes in the sequence. |

|

| |

Although an acceptable solution

was obtained for this small problem, the search becomes more

difficult as the problem size grows. It also becomes more difficult

as we add complexity to the problem by making the early and

late times restrictive and as more resources are added. The

worksheet evaluation for each solution depends on the size

of the problem. Even one pass through the improvement

process takes a large number of individual evaluations. |

Buttons |

| |

At the top of the page there are

four buttons. The first button displays the Search dialog

shown earlier. The Map button creates the map of the

current solution. This is the same map as the one created by

a similar button on the results page. The buttons on the right

open the unique Results worksheets

corresponding to the Model worksheet.

The yellow cells in the Model worksheet are linked

by formula to the data on the Data worksheet. Any

value changes there are immediately reflect on the model worksheet.

If the number of trucks or deliveries is changed the model

worksheet must be regenerated by the button on the data worksheet.

To the right of the buttons are statistics concerning

the computations obtaining the solution. The example required

4083 solution evaluations (called runs). The average number

of runs per second depends on the speed of the computer. The

runs per second decreases as the size of the problem increases.

The total search time is 44 seconds. A local optimum was obtained.

The heuristics used for searching the solution

space are described on the next page. |

| |

|

|