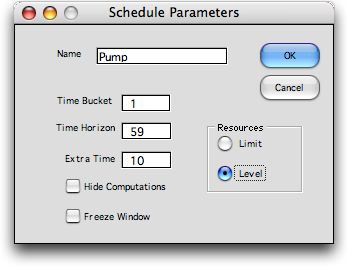

For this model

we choose the Level button in the schedule dialog.

For

the level model we want to minimize the variation of resource

usage about the amount of the resource available. The objective

reflects the goal of having a uniform amount of the resource

used during the life of the project without great variations

above or below the amounts available in the different periods.

The mathematical development is below. The variation of the

resource depends on the schedule through the x variables

and the amount of variation is represented by the s

variables. The variation in any one period may be positive or

negative, but the squared value used in the evaluation is always

positive. As for the limit model, the amounts available (R)

may vary over the periods in T. Although we allow the

cost of variation (c) to vary over time and resource,

for most cases it would be appropriate to use 1 for all values.

An interesting observation occurs if we say that the amount

of the resource is constant over time. In the following we assume

all variation costs are 1 and that the resource available (R)

does not vary with time. We expand the squared term

In the final expression for the cost of variation

we identify two terms using the large brackets. The first is

a constant that does not depend on the schedule. The second

term does depend on the schedule and is the sum of the squares

of resource usage over time. For optimization, any constant

term can be neglected without affecting the optimum solution,

so the optimum only depends on the sum of the squares of resource

usage. The values used for resource availabilities (R)

do not affect the optimum solution when the goal is to minimize

the cost of variation.

This result is not true if the resource availability

changes over time. The analysis also depends (in the second

line from the bottom) on the fact that the total time required

for each activity, and thus the total resource required, does

not depend on the schedule. This is not true if some of the

activities using resources are variable

time activities.

The analysis also assumes that the time required

for the project (T) is constant and does not depend

on the schedule. This is not true if the optimization allows

the total time to change with the schedule. If we allow the

time to change, it may be possible to reduce the sum of the

squares by spreading out the project into more periods. This

may or may not reduce the total variability or the average

variability in time. We do not adjust the analysis for this

because it is unlikely that the project duration will be

allowed to extend many periods beyond the due date. The resultant

approximation is small.

When variability is more important for one resource

than another, the cost parameters (c) many be different

for different resources. This does not change these results

unless the costs vary over time.

The figure below shows the Gantt chart when variance

is the measure to be minimized. Rows 31 and 32 show the amount

used and available in each period. Row 33 shows the difference

between the amount used and the amount available squared. The

variance cost is evaluated in row 35. Since the unit cost is

1, rows 33 and 35 are the same. When there is more than one

resource, rows are provided for each. |